Troubleshooter Column

Avoiding pitfalls in the design of LFAM composite components

Recoat temperature, part orientation and bead geometry are some key design variables to consider for a successful and reliable large-format additive manufacturing (LFAM) process.

Nondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreAerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreGuidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Louis Dorworth

Direct Services Manager, Abaris Training Resources

Proper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

Read MoreThe importance of resin mixing procedures in the composites shop

What is considered to be common knowledge when storing, handling, weighing, mixing and deploying epoxy resins and adhesives has brought to light the need for tighter control, improved practices.

Read MoreWhy does my composite mold leak under vacuum or applied pressure?

Louis Dorworth of Abaris Training Resources outlines key considerations to make when fabricating quality composite molds to minimize risk of leakage under pressure or vacuum.

Read MoreDoing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreTroubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

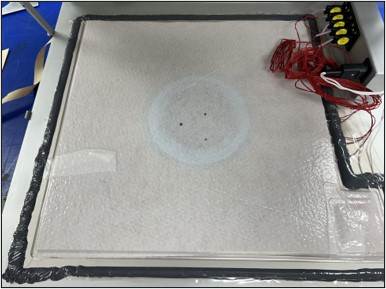

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Louis Dorworth

Direct Services Manager, Abaris Training Resources

Alternate heat sources for hot-bonded composite repairs

Successfully using an alternate heat source for repairing composite structures requires an awareness of thermal dynamics and effective heat transfer management.

Read MoreA second look at cobonded tapered scarf repairs for composite structures

Composites repairs, such as cobonded tapered scarf repairs, seek to sufficiently restore structural loads so that components perform without failure

Read MoreAvoiding the pitfalls of vacuum infusion processing

Understand the fundamentals of vacuum infusion processing (VIP), including pressure, permeability and race tracking, to prevent issues and produce consistent results.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreChallenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

Read MoreFastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Troubleshooting failures in adhesive-bonded composite joints

Cause of adhesive bonding inconsistencies or failure may be numerous. According to Louis Dorworth, the following points should be examined to determine the culprit.

Read More