Composites Materials Testing

Within the context of composites testing, the standard “building block approach” is a step-by-step series of mechanical tests of increasing complexity, coupled with analyses performed at each step, that serves as a framework for designing composite structures. In the building block approach, the levels or “blocks” each serve specific purposes and are addressed sequentially, starting from the bottom: Level 1, Coupon-level testing Level 2, Element testing Level 3, Subcomponent testing Level 4, Component testing

Latest Materials Testing Articles

VIEW ALLRadalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

WatchORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

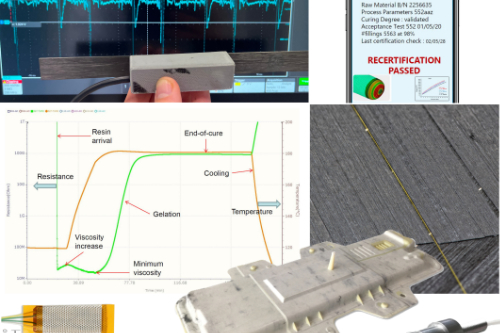

Read MoreThe evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreUniversity of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

Read MoreAsahi Kasei launches cloud-based CAE platform for FRP deformation prediction

An on-demand mapping tool for anisotropic materials and polymer material fracture prediction model, i-Lupe, aims to help predict impact, crash behaviors.

Read MoreKnowledge Centers

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Materials Testing News And Updates

Thermoset prepregs meet lightning strike protection specifications

CAMX 2024: A.P.C.M. highlights how its range of epoxy prepreg offerings undergo and surpass lighting strike testing.

Read MoreDigital chemistry platform leverages physics-based modeling for enhanced workflow

CAMX 2024: Schrödinger introduces a digital chemistry software platform, designed to enable researchers to tackle materials challenges across diverse polymer resin and carbon fiber applications.

Read MoreUniversal test system, testing fixtures provide standardized composites testing

CAMX 2024: MTS Systems showcases the Criterion 43 universal test system with a custom software interface, as well as composites testing fixtures and contact and noncontact extensometers.

Read MorePrecision universal testers optimize materials testing, analysis

CAMX 2024: Fast and flexible AGX-V2 Series by Shimadzu provides more intelligent operability for testing tasks, supporting composites, plastics, metals and finished products.

Read MoreNoncontact digital gage enables precise materials, structural testing

CAMX 2024: Trilion Quality Systems is showcasing the Aramis optical strain gage, a material-independent measurement device with 3D-DIC capabilities.

Read MoreComposites lab launches fresh rebrand to highlight material services

JEC World 2024: With new logo and rebranding in hand, Composite Test & Evaluation Ltd. invites industry and potential partners to learn more about its decades experience in material, evaluation services.

Read MoreFeatured Posts

Laser-excited acoustics provide contact-free, nondestructive composites inspection

Xarion’s couplant-free NDT technology uses laser physics and a membrane-free optical microphone, eliminating the requirement for fluid coupling, widening the scope for NDT technology.

Read MorePhotothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

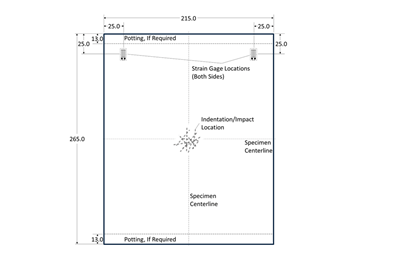

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreNotched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreRemembering Don Adams

When one thinks of composites test methods, one thinks of Don Adams. Don passed away at the end of 2022. We remember him here.

Read More

.jpg;maxWidth=300;quality=90)