Infusion success starts with “R2O”

Vectorply’s “Road to Optimization” crucial in Cruisers Yachts 390 Express Coupe infusion

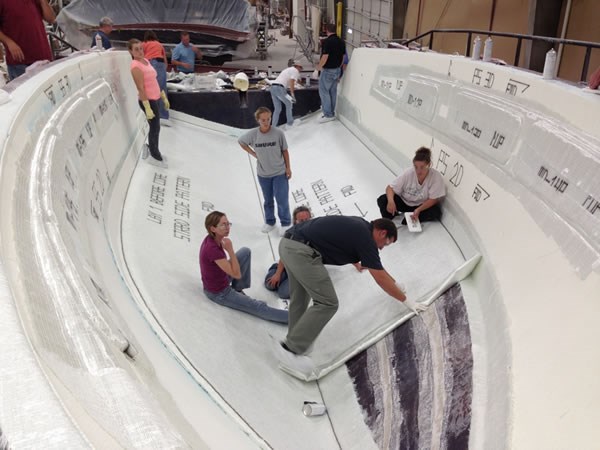

Making the switch from open molding to vacuum infusion can be a daunting challenge, particularly when the first large part to be infused is a newly designed 39’ boat hull. In order to help transition their new 390 Express Coupe to infusion, KCS International, manufacturer of Cruisers Yachts, enlisted the help of Vectorply’s Engineering Services Team.

Vectorply employs four full-time engineers to help lead customers down the Road to Optimization (R20) where the goal is to optimize customer’s workflow from initial audits, part and laminate design, to material selection and processing.

The work began before the hull mold, which was split down the middle due to complex geometry and to reduce major repair hours, was even delivered. The hull bottom and sides were analyzed using the requirements outlined in ISO 12215 with Vectorply’s VectorLam software. VectorLam is an Excel-based classical laminate theory (CLT) analysis program that allows users to compare laminates, design plates and stiffeners, as well as analyze hull scantlings using requirements from ISO 12215 and DNV High Speed, Light Craft and Naval Surface Craft.

Once initial laminates were developed, a team consisting of Vectorply, Composites One, 3A Composites (Baltek) and CCP assembled to produce test panels to verify resin flow characteristics and mechanical properties as well as surface cosmetics. Multiple iterations of test panels were made which included changes in reinforcement fabrics, core materials, resins, barrier coats, and catalysts in order to meet Cruisers’ surface cosmetic requirements.

The final hull side and bottom laminates utilized Vectorply’s E-QXM 3515, which is a 35 oz/yd2 quad-axial fabric with a 1.5 oz/ft2 chopped strand mat attached. Also utilized were balsa core and Lantor Soric products from 3A Composites as well as gelcoat and resins from CCP. Fabric and core materials were all kit cut by Mahogany Company.

The surface profile of the chosen infusion laminate schedule rivals most open mold laminates with quality and consistency unattainable in traditional open molding. Staff from Vectorply, Composites One, 3A Composites, CCP and Mahogany were all on-site for the infusion of the first hull to provide training to Cruisers employees and demonstrate best practices. The results of the switch from open molding to infusion were easy to see. Cruisers was able to reduce the finished hull weight by over 800 pounds, and they also reduced layup time from 6 days to 4 days, all while improving laminate quality and consistency.

Why not let the Vectorply Engineering Services Team lead you and your next project down the Road to Optimization!

In this photo, the skin coat is complete and the team is preparing to load the dry fabrics.

Vectorply Field Engineer Mike Ditzler helps load the hull’s outer skin

Mike Ditzler inspects the infusion half-way through

With the hull infusion complete, the team monitors the part for leaks.

Pictured is the completely-infused hull ready for transom installation.