Designing composite parts and structures, because of their complexity, has always been a challenge, but the shift by OEMs toward digital twins and traceability is putting new pressure on the composites industry to more tightly integrate CAD/CAE data with as-manufactured data.

Further, the advent of promising new materials and processes is spurring demand for rapid qualification and certification. One way to achieve this is to increase the use of virtual testing and qualification to give OEMs and fabricators the confidence they need to specify new materials. This CW Tech Days will assess the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

Your $149 investment will provide valuable, high-utility information to help you understand how design engineering is evolving in composites manufacturing.

During nine 30-minute Tech Day webinar sessions, materials and design engineering experts will assess the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

Application of digital engineering methods to support the development and certification of composite unmanned air vehicles

Presented by Gerardo Olivares

Digital engineering (DE) is a formalized methodology used to support the requirements, design, analysis, verification and validation associated with the development of complex systems. In contrast to document-centric engineering, DE puts models at the center of system design. This presentation will describe the five elements required to apply digital engineering principles to develop and certify composite aircraft structures. An application of this approach will be presented to show how NIAR envisions the use of DE to support the development and certification of future composite UAVs.

Validated simulations for additive manufacturing

Presented by Eduardo Barocio

Additive manufacturing has enabled producing complex geometries that could not be produced with traditional methods and at scales of multiple meters. However, the multiple phenomena developed during the printing process can lead to residual stresses, warpage or delamination that can result into expensive print failures. Hence, validated simulations are paramount to enhance the confidence in additive manufacturing (AM) technologies and to accelerate product development. Simulation predictions for large scale additive manufacturing carried out with Additive3D (a physics-based simulation workflow for additive manufacturing) will be demonstrated in this presentation.

De-risking the hybrid overmolding design process

Presented by Pete Levesque

Thermoplastic composites have gained significant traction in aerospace and automotive markets in the past decade. New polymers such as LMPAEK have proven to be enablers for consolidation, welding and forming due to their wide and forgiving processing windows. These processing windows also enable designers to more easily achieve complex geometries by hybridizing thermoplastic composites with traditional injection molded plastics. In this presentation, Pete Levesque will review how Victrex is leveraging existing software packages for designing and de-risking thermoplastic composite hybrid overmolded designs.

Material trades strategies for composite structures

Presented by Craig Collier

Weight savings (or lightweighting, as referred to in the auto industry) remains very important to aerospace and is achieved with advanced composite materials. When making composite structures, commercial transports (like a 737) and UAMs (like eVTOLs) are taking advantage of new materials. Whereas the UAM manufacturing focus is on high volume shipsets, the commercial airframe OEMs are focused on manufacturing rate—the speed at which they can produce a plane to meet airline demand. Meeting these needs is realized with the full potential of newer material systems such as next generation thermosets, thermoplastics and resin infusion. These newer materials and their processing offer the opportunity to open the design space of vehicle configurations and design concepts. Along with material technology advancements are new software tools just now available. HyperX is one such tool that enables efficient trade studies of design possibilities that interactively steps a practicing engineer through a series of design optimizations from conceptual to preliminary rapid sizing to critical detail sizing and all the way to part release and certification reports. Consistent analyses and material allowables are used throughout the process. This presentation is a live demonstration of optimizing the acreage surfaces and the fastened and bonded joints of a commercial transport stiffened panel wing and that of a UAM sandwich panel wing.

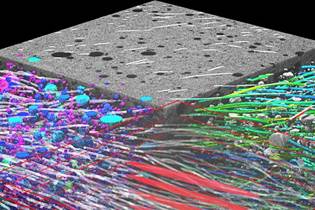

Computed tomography: from R&D to inline quality assurance for composites

Presented by Pascal Pinter

Computed tomography (CT) is a great tool for material characterization and quality assurance throughout the entire product life cycle of composite structures—from research and development to production and complaints investigation. For example, in material and component development, fiber orientations can be calculated based on CT scans to validate flow or draping simulations. The same data can also be used for finite element (FE) simulations in structural mechanics to improve material efficiency, to design cheaper and lighter components with the same or higher reliability, or to investigate the integrity of entire components at end-of-line inspections.

The integration and democratization of multi-scale material modeling, manufacturing simulation and structural simulation to advance composite design and analysis

Presented by Jeff Wollschlager

Composite design and analysis technologies have advanced significantly since the technology of the late 20th century. Unfortunately, much of this technology is currently not being applied by the mainstream user base, but indeed still resides with early adopter experts. In order to make steps toward the future in advanced composite design and analysis, integration and democratization of two main topics needs to be developed. First, more accurate and computationally efficient advanced material modeling with multiscale technology is needed to capture more “correct” physics at the constituent scale. Second, the integration of induced residuals and orientations available from manufacturing simulations as initial conditions into structural simulations is required to capture the correct homogenized stress/strain states. In the end, what this means is migrating from a homogeneous isotropic world to a heterogeneous anisotropic world and making that transformation easy for users. To highlight the integration and democratization developments occurring within the Altair Composites Solutions team, a demonstration of the injection molding and composite pressure vessel (CPV) workflows within the Altair HyperWorks product suite will be shown and discussed.

New space: use of digital tools to enable the digital factory and to create digital twins

Presented by John Courter

Firefly Aerospace is an emerging leader in economical launch vehicles, spacecraft and in-space services. Founded in 2017, Firefly has rapidly innovated and developed products for the marketplace that include the largest liquid-propellant, all-composite orbital launch vehicle Alpha, Blue Ghost Lunar Lander and in-space transportation solutions.. Firefly uses many commercial off-the-shelf (COTS) materials in non-standard ways to populate products digitally and rapidly iterate both through digital optimization and a "make it, break it, make it, fly it" approach. John Courter, director of the aerospace structures group at Firefly, will share some of these experiences and expand on what Firefly believes to be a mutually-beneficial supplier-consumer relationship.

Using material digital twins and machine learning to more accurately predict as-manufactured performance

Presented by Pierre-Yves Lavertu

Integrated computational materials engineering (ICME) enriches CAE analyses by connecting the manufacturing process, material properties and part performance to create a deeper connection between physical and simulation worlds. Manufacturing processes for composite materials are known to impact material microstructures and this needs to be captured in order to predict accurate and reliable part performances. Using ICME increases lightweighting potential while reducing product development time and cost. Based on a multi-scale material modeling technology, material digital twins provide an accurate understanding of the material behavior and enable predictions on the performance of composite materials. Virtual material testing reduces the number of experimental tests to be performed and is used to efficiently screen different materials and microstructures for an optimized performance. In addition, machine learning techniques can be leveraged to further accelerate the material data generation and selection. The following example will be used to highlight the benefit of material digital twins and ICME-based simulations: automatic fiber placement induces fiber orientations and the presence of tow gaps or defects during the manufacturing process of parts.

Design automation for composite airframes

Presented by Bruce Gabel

This presentation will show how Spirit AeroSystems fully automated the design of composite frames within CATIA. It will show how a complex part can be broken down into discrete segments to facilitate the automation of design across a family of parts.