BigRep, Teton Simulation partnership integrates SmartSlice into large-format 3D printing

High-quality, production-level parts capability now available for large-format 3D printing, with current compatibility with BigRep PRO HT and HI-TEMP CF filament materials.

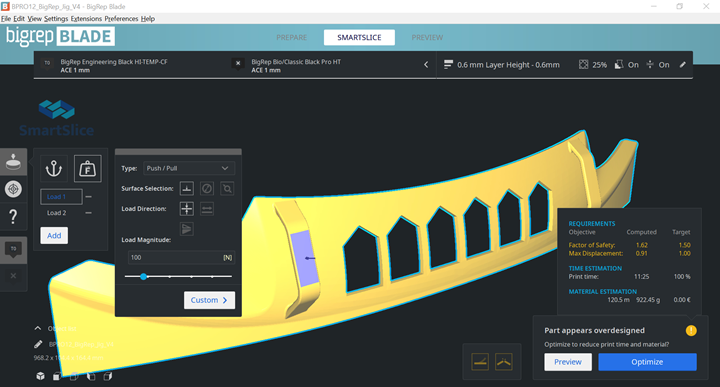

BigRep (Berlin, Germany), a large-format fused filament fabrication (FFF) 3D printing company, and Teton Simulation (Layramie, Wyo., U.S.), the creators of SmartSlice technology for optimizing 3D printer performance, have partnered to bring the benefits of performance requirements-based validation and print parameter optimization to industrial large-format prints.

“We are excited to work with Teton Simulation and explore the possibilities of their advanced FEM technology,” says Dr. Sven Thate, managing director of BigRep. “We are convinced their industry-standard design verification will boost large-format FDM [fused deposition modeling] usage even in the most load-critical applications. We also see the possibilities of their load based design optimization to deliver significant time and materials savings and make FDM usage on industrial level easier than ever.”

SmartSlice helps industrial users to quickly define load cases for parts they intend to print and validate the as-printed performance of these parts against mechanical limits of the material but also against part deflections. With built-in optimizer features, users can also let the software find the ideal slicer settings individually for each section of a 3D geometry, guaranteeing load-performance with minimal amount of material. The product currently works for FFF 3D printing for plastics and polymers, but other variations are in the works.

“Teton Simulation is excited to announce our collaboration with BigRep to bring the power of SmartSlice to large-format prints. BigRep’s ability to create high-quality, production-level parts at such a large scale provides a great opportunity to reduce material waste, increase efficiency and save project costs,” adds Teton Simulation CEO Doug Kenik. “And with BigRep BLADE slicer software we have the perfect vehicle to harvest the full power of SmartSlice, bringing significant benefits to the users.”

The output of this partnership is expected to bring confidence that parts meet functional and performance requirements as well as time, money and material saving possibilities with automated part analysis and optimization from small- to large-format 3D printing. Currently working with BigRep materials, including PRO HT bio-performance filament and HI-TEMP CF, a high-strength and heat-resistant engineering-grade filament, the integration will be previewed at Formnext 2021, Nov. 16-19, 2021, in BigRep’s booth.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Aurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.