GE Aviation delivers 25,000th CMC component

The Asheville, NC, US facility has reached a production milestone for its ceramic matrix composites components for commercial aviation.

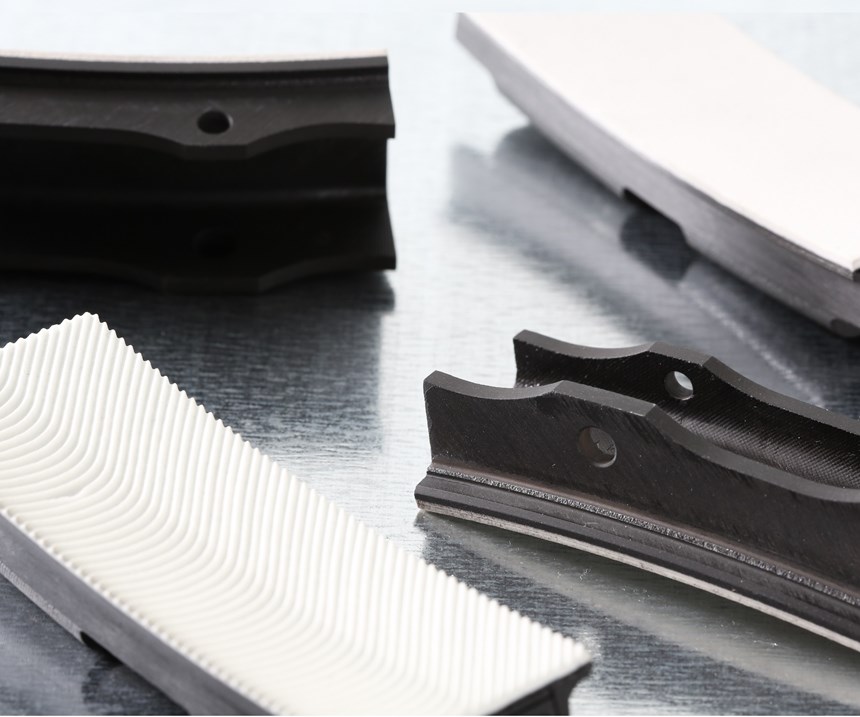

GE Aviation (Evendale, OH, US) announced on Aug. 8 the delivery of its 25,000th CFM International (Cincinnati, OH, US) LEAP engine turbine shroud by its Asheville, NC, US facility. This ceramic matrix composites (CMCs) production milestone for the company arrives just five years after the opening of its Asheville site. Shroud production rates for the LEAP program have more than tripled each year since the site opened. Today, these Asheville-produced shrouds have surpassed more than 1.5 million flight hours on the 800+ LEAP engines in commercial airline service.

CMCs are around one-third as heavy as metals and can operate at 2,400°F — 500° higher than the most advanced alloys. According to GE Aviation, the next generation CMC material technology being will improve fuel efficiency at 1 to 2 percent.

In May, GE Aviation Asheville began delivering CMC components for the GE9X, the world’s largest commercial jet engine. With an 11-foot diameter, the GE9X can generate more than 100,000 pounds of thrust. By the end of 2018, GE Aviation Asheville will deliver five separate CMC parts for the engine, which is scheduled to enter service by the end of the decade on the Boeing 777X.

Related Content

-

GE Aerospace awarded demonstration contract for NASA HyTEC project

Turbofan engine small core technology development with CMC-coated components targets enhanced fuel efficiency in single-aisle aircraft by mid-2030s.

-

MATECH’s FAST technology achieves ultra-high density C/C composites

Targeting demanding hypersonic missile applications and ballistic reentry, the patent-pending process increases C/C composite ablation and oxidation resistance by 20 times.

-

ORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

.jpg;maxWidth=300;quality=90)