ModuleWorks, Cetim partner to simplify cost estimations for manufacturing

Capable of supporting composite materials, integration of Self-Drive CAM with TechniQuote software speeds up, enhances accuracy of toolpath-based cost estimation for machining operations.

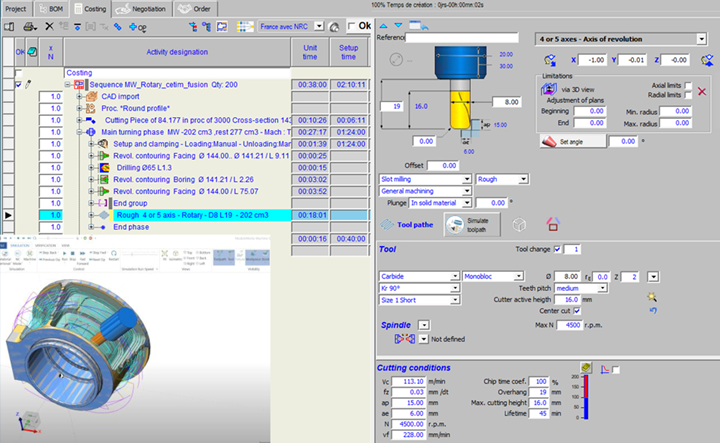

Cetim (Senlis, France), the Technical Centre for Mechanical Industries, has integrated software component provider ModuleWorks’ (Aachen, Germany) Self-Driving CAM into its TechniQuote cost estimation software. The self-driving technology with built-in toolpath generation simplifies and speeds up cost estimations for milling. TechniQuote software, already compatible with composite materials, is also capable of creating cost estimates for a variety of composites with the integration of Self-Driving CAM.

TechniQuote cost estimation software is used to generate detailed cost breakdowns and make informed decisions about pricing, process optimization and resource allocation for mechanical manufacturing. To generate an estimate, users load a CAD model and set up the machining scenarios. For milling jobs, the integrated Self-Driving CAM enhances TechniQuote with pre-defined machining templates to simplify and accelerate the cost estimation process.

“Estimations based on toolpath data are more accurate than those based on other costing methods, but both skill in machining and time are required to enter relevant CAM parameters,” Hervé Lallemand, costing product manager at Cetim, explains. “With machining rules and data provided by TechniQuote and with Self-Driving CAM, users now just select very few parameters that control pre-defined CAM templates. This greatly speeds up the estimation process and users can respond rapidly with accurate pricing.”

TechniQuote uses automatic feature recognition in addition to the machining templates to help engineers quickly set up and run comparative cost analyses. The integrated Self-Driving CAM is built upon the ModuleWorks toolpath algorithms which deliver precise information on the length and complexity of the toolpath, enabling TechniQuote to accurately estimate the total machining time as well as other cost factors such as tool wear, waste material and overall energy consumption.

.jpg;maxWidth=300;quality=90)