Thomas Tison, nlcomp head biocomposite ecoFoiler development

The fully recyclable, 3.80-meter foiling dingy concept, as demoed at JEC World 2023, sets the bar for watercraft that are accessible to a broad spectrum of sailors.

French firm Thomas Tison Yacht Design & Engineering (Lorient, France) and Northern Light Composites (nlcomp, Monfalcone, Italy), a Northern Light Sailing Team spin-off, are developing an ecoFoiler, a 3.80-meter foiling dinghy, made with nlcomp’s recyclable rComposite materials, with a focus on sustainability and performance.

According to the partners, the ecoFoiler design will make it easy to handle before and after takeoff, unlike other high-performance foiling dinghies that can be challenging to sail and tend to fly very high. This feature makes it an ideal product for serious sailors of all levels, offering a thrilling sailing experience. The ecoFoiler also caters to sailors who value optimized design details, ease of use and environmental sustainability.

Thanks to Thomas Tison’s expertise in composites engineering and designing advanced racing yachts, and to nlcomp’s expertise in biocomposites manufacture, the ecoFoiler weight will be comparable to its non-eco-friendly alternatives.

“While there are several foiling concepts in the market, the ecoFoiler is going to set the bar high,” the designers say. “It will be the first production foiling dinghy to be designed with biocomposite materials, offering a refined, fast design that ensures ease of sailing.”

In 2022, Thomas Tison launched a custom sailboat featuring a high-tech wooden hull and conducted research and a lifecycle assessment (LCA) to measure the impact of its design on reducing the boat’s carbon footprint. Now, its partnership with nlcomp represents an opportunity to drive innovation in this field using biocomposite materials, embodying the same spirit of progress and innovation seen in the America’s Cup, now applied to sustainable construction.

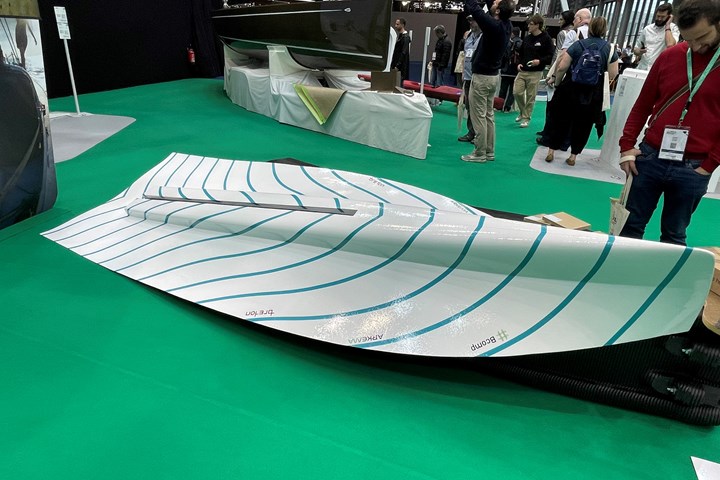

3D printed mold by Breton, used to produce the ecoFoiler prototype. Photo Credit: Nlcomp

“I’m glad to have the opportunity to work with nlcomp as they are a passionate team and they are leading the way with their vision for sailing in a sustainable way,” Thomas Tison says. “Eco-composite and foiling projects are now reaching a wider audience. We will analyze and optimize every phase of the construction and production process to ensure that the ecoFoiler is accessible to a broad spectrum of sailors seeking the thrill of foiling with a minimal carbon footprint. Our goal is to transform this concept into a boat that can provide this unique experience to as many people as possible.”

The ecoFoiler hull prototype was unveiled at the JEC Industry Planet at JEC World 2023 (shown above) using Bcomp’s (Fribourg, Switzerland) ampliTex reinforcements to replace traditional glass fibers, recyclable Arkema (Colombes, France) Elium resin and produced via a Breton SpA (Castello di Godego, Italy) 3D-printed mold, using the company’s Genesi machine and a recyclable thermoplastic polymer. The team, led by Thomas Tison, will optimize the hull shape, develop the deck, the sailplan and the foiling system to ensure optimal performance.

“We are really looking forward to collaborating with Thomas on this project,” Fabio Bignolini, cofounder and CEO of nlcomp, says. “I had been following his work for the past few years, and after meeting him at The Yacht Racing Forum, I immediately knew that he was the perfect partner to help us develop the ecoFoiler.”

Nlcomp’s previous project, the ecoracer25, already proved to the industry that sustainable performance is possible. In 2022, the company’s first recyclable sport boat won the Italian Sportboat championship held in Lake Garda against a fleet of 40 fiberglass competitors.

Related Content

REGENT progresses seaglider prototype development, prepares for crewed testing

All-electric composites-intensive maritime craft will enhance coastal transportation capabilities by mid-decade.

Read MoreNlcomp launches recyclable composite sailing boat Ecoracer30

Italian startup featured its 30-foot sustainable production boat at the Ocean Race Grand Finale in Genoa, Italy, citing the challenges, highlights and future related to its development.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreOrbital Composites installs robotic AM system at University of Rhode Island

The 12-axis Orbital S system designed to print continuous fiber-reinforced parts will be used to advance research in composites for underwater unmanned vehicles.

Read MoreRead Next

INCA secures $40 million funding commitment for biocomposites development

INCA Renewable Technologies targets commercialization of hemp-based biocomposites line for automotive, wind, marine industries, moves forward with processing facility construction.

Read MoreThis foiling racer is crazy fast thanks to composites

The Exocet racer’s hull and its foils, designed via computer model, are fabricated using hand layup and resin infusion methods, respectively, with PRO-SET epoxy.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)