TPRC joins aviation projects with thermoplastic composites focus

TPRC advanced materials expertise will be applied to Luchtvaart in Transitie and FENIKS with a primary aim to make aviation more sustainable.

ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) is kicking off two separate projects, Luchtvaart in Transitie and FENIKS, whose primary goals are to accelerate aviation sustainability through the development and application of thermoplastic composite parts and structures. TPRC will be applying its advanced materials expertise through both.

The Luchtvaart in Transitie kick-off meeting took place in December 2023. Translated as “Aviation in Transition,” the Dutch project features more than 60 parties participating in 12 subprojects. The subproject STC, translated from Dutch as “Materials, production technology and constructions for ultra-efficient airplanes,” has recently been granted. It will focus on the development of innovative manufacturing technologies for complex thermoplastic composite parts and integrated structures. Specifically, the innovations to be developed will focus on minimizing environmental impact, from incoming materials to delivery to aircraft manufacturers such as Airbus and Boeing, with a target of at least 30% compared to current comparable products. To reduce air resistance, techniques are being developed to apply functional coatings and microstructures, with an estimated fuel saving of 2-5%.

In 2023, knowledge development processes were started. The first choices for product concepts and technological demonstration products have also been made. Consortium members hope to demonstrate new materials, production and product concepts for new aircraft platforms and the selection of promising technologies by 2026. TPRC is looking forward to contributing to these project goals with a dedicated team of experts and essential lab facilities in the coming years.

The project is in collaboration with the Ministry of Infrastructure and Water Management and is co-funded by the National Growth Fund. Learn more about Luchtvaart in Transitie and its partners here.

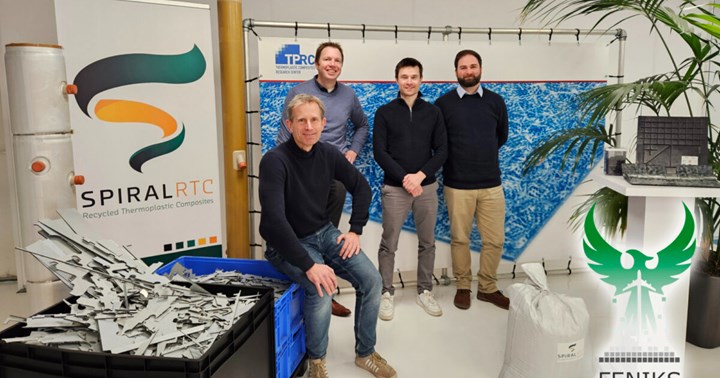

“FabricagE New cIrcular fiber-reinforced KunstStof components for aerospace,” or FENIKS, is another project, spanning 4 years between TRPC and Spiral Recycled Thermoplastic Composites (Enschede, Netherlands). Supporting the use of recycled thermoplastic composites in the manufacture of aerospace applications will be a focus topic to meet project goals. FENIKS is funded through the Dutch Ministry of Economic Affairs and Climate and the Netherlands Enterprise Agency (RVO).

For related content, read “TPRC brings composites expertise to NxtGen HighTech program.”

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.