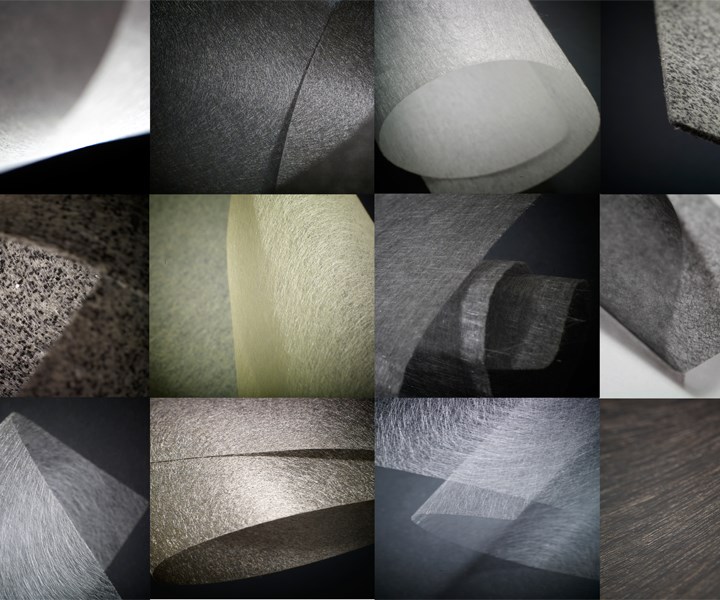

TFP's new lightweight veils target high-temperature applications

The new polyimide and basalt veils are part of TFP’s OPTIVEIL range and have been developed specifically to expand TFP’s selection of high-temperature materials.

Source | TFP

Editor’s note: CompositesWorld received several new product and technology announcements ahead of JEC World 2020, which had been scheduled for March 3-5. Although that exhibition was postponed to May, CW is now publishing the announcements we received. This is one of them.

Technical Fibre Products (TFP; Burneside, U.K.) is introducing new, lightweight veils designed for high-temperature performance in composites. The new polyimide and basalt veils are part of TFP’s OPTIVEIL range and have been developed specifically to expand TFP’s selection of high-temperature materials.

The polyimide veil is the highest temperature stable polymer veil that TFP manufactures, with a maximum service temperature of above 260°C, which, TFP says, is significantly higher than that of other polymers such as polyester and PPS. The material was developed as a high-performance insulation material for space applications, designed to offer the temperature stability necessary to withstand missions to Mercury and the sun.

The basalt veil has been developed as a more temperature stable alternative to TFP’s standard E & ECR glass veils. It is stable up to 850°C and retains its integrity when in contact with an open flame, making it suitable for applications requiring a fire barrier. Basalt, like glass, also has a high resistance to acid and alkali, which makes it ideal for use in corrosive environments.

As well as increased temperature stability, these new materials also offer the uniformity and surface quality synonymous with TFP’s OPTIVEIL and OPTIMAT ranges, which include carbon, glass, metal coated, aramid, recycled carbon and thermoplastic nonwovens. This quality of dispersion makes the materials suitable for a wide range of composite applications including surface finish, improving resin flow, adhesive carriers and imparting functionality where required.

TFP is also be exhibiting new TECNOFIRE developments for the fire protection of composite structures. The company’s latest E8AI Mat is formulated with AES fiber, which has a classification temperature of 1100°C to 1300°C and also offers improved temperature stability for fire protection applications. Other TECNOFIRE development materials on display include a lightweight intumescent veil for use in aircraft, which is incorporated into aerospace composites to improve the fire smoke toxicity (FST) with minimum weight addition.

Related Content

-

Park Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

-

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

-

Heat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

.jpg;width=70;height=70;mode=crop)