9T Labs assesses AM for medical, aerospace applications

9T Labs conducts two studies to assess the viability of its Red Series additive manufacturing system to manufacture a carbon fiber/PEKK aerospace hinge and a surgical tool.

Share

Read Next

Rendering of design for 9T Labs 3D-printed aerospace bracket. Photo Credit: 9T Labs

9T Labs (Zürich, Switzerland) manufactures the Red Series of Additive Fusion Technology (AFT) systems for the fabrication of continuous fiber-reinforced polymer parts. The system features three components: Fibrify design software, a 3D printer called a Build Module and a Fusion Module that consolidates the printed part. The build volume of Red Series is 350 x 270 x 250 millimeters and materials available are carbon fiber/PEKK and carbon fiber/PA12, with 60% fiber volume fraction (FVF).

9T Labs recently revealed details of two recently completed studies that assessed the feasibility of using Red Series to replace an existing metallic part. One is an aerospace hinge and the other is a surgical tool, called an aiming arm.

The hinge is currently made from steel and features a vertical plate mounted on a base plate with four fastener holes in it. The study evaluated topology optimization and redesign, multi-body strategy, reinforcement strategy, weight reduction and cost analysis. Topology optimization led to an optimized redesign, followed by development of a manufacturing strategy. The decision here was to fabricate the hinge in parts — vertical plate and a two-component base plate — and then join those during consolidation in the “fusion” process. The Fibrify software guided development of a fiber layup strategy for each hinge component, which involved multiple layouts for each. Material is a combination of neat PEKK (35%) and carbon fiber/PEKK (65%). Part volume is 18.3 cubic centimeters; part weight is 27 grams, which represents a 78% savings compared to the steel version. 9T Labs’ production cost analysis evaluated tooling, material, equipment and labor costs and determined that the composite replacement would cost 50% less to manufacture than the steel legacy part.

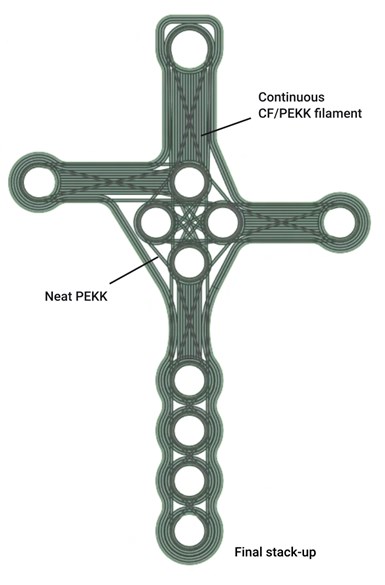

Final stack-up for 9T Labs 3D printed surgical tool. Photo Credit: 9T Labs

The surgical aiming arm is a T-shaped aluminum alloy device with multiple holes in it, used to align surgical tools during an operation. It sees relatively modest mechanical loads, but undergoes multiple sterilization cycles and must maintain excellent dimensional accuracy. X-ray translucency is also critical. The layup strategy focused on development of robust external surfaces and dimensional stability of the holes, which was achieved by directly interconnecting the holes via fiber placement. The final design features 90 additively manufactured layers to create a through-thickness of 20 millimeters. Materials are neat PEKK (60%) and carbon fiber/PEKK (40%). Part volume is 62.5 cubic centimeters; part weight is 88 grams, which represents a 48% weight savings compared to the aluminum version. The production cost analysis performed was the same as that for the aerospace hinge and showed potential savings of up to 68%.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.