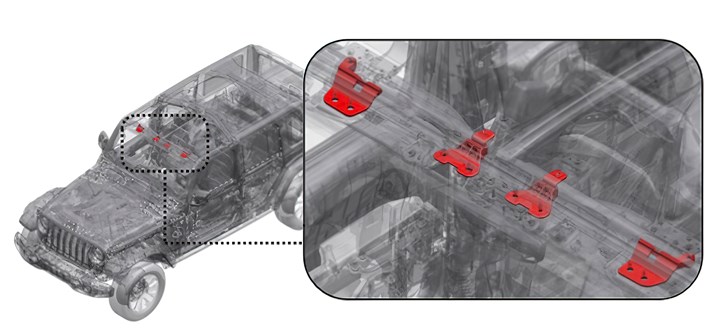

What is said to be the first high-volume structural body application in a weatherable, molded-in-color (MIC) carbon fiber-reinforced thermoplastic (CFRTP) debuted on a series of roof receivers (brackets) to secure hardtops and soft tops on 2021 Jeep Wrangler SUVs (shown above) and Gladiator pickups from Stellantis. The composite material offered comparable mechanical performance at significantly lower weight than the benchmark steel. Photo Credit (for this image and image in line with title): Stellantis

Decades of experience and conventional wisdom have taught that the longer the fiber reinforcement, the higher the mechanical performance of the resulting composite. Although the introduction of nanocomposite additives have, to some extent, challenged that assertion, a family of ultrashort (but not nanoscale) carbon fiber (USCF)-reinforced thermoplastics (CFRTP) designed for injection molding has been shown to consistently outperform short- and long- (glass or carbon) fiber thermoplastics. This is particularly true in complex geometries where it is difficult to achieve good fiber penetration in fine or tall part details. In fact, not only can these compounds — called KyronMax and available from Mitsubishi Chemical Advanced Materials Inc. (MCAM, Mesa, Ariz., U.S.) — outperform conventional thermoplastic composites, but they also outperform metals. A great example of this is a series of roof receivers (structural hold downs/brackets) used to secure removable soft tops or hardtops on 2021 Jeep Wrangler sport utility vehicles (SUVs) and Gladiator pickups from Stellantis (Auburn Hills, Mich., U.S.). This is the story of how the application came to be.

Strong enough for aerospace, fast enough for automotive

KyronMax compounds were originally developed for aerospace and later expanded into performance sporting goods applications where a high-temperature thermoplastic matrix was an advantage and where the ability to achieve high fiber penetration in intricate geometry was vital to meet demanding mechanical requirements at low weight. Not surprisingly, these materials are gaining interest in automotive, since the injection molding process is well suited to meet that industry’s high production volumes, high repeatability and reproducibility (R&R) requirements and very competitive cost targets.

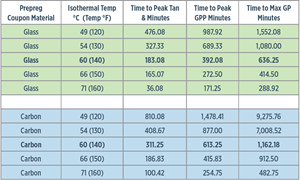

Image illustrated by Susan Kraus.

Development of the composite roof receivers began with a meeting to discuss new materials that MCAM had in its portfolio that might be of use to the Innovation Group at then Fiat Chrysler Automobiles (FCA, now Stellantis). After a discussion about the KyronMax product line and a review of datasheets for several products with different matrices and fiber weight fractions (FWFs), which were then shown to and discussed with multiple FCA application engineering teams on different vehicles, FCA’s Innovation Group decided to explore these materials further and started looking for an application where the compounds’ capabilities could be evaluated.

The Jeep roof receivers, which were originally produced in investment die-cast steel, were identified as a good choice since the parts were structural and were of modest size but had complex geometry where it would be important to achieve good fiber penetration. Additionally, given their location at the top of the roof, if a significant weight reduction could be achieved, then that would contribute to lowering the center of gravity (COG) of the vehicle, which would improve handling and stability for vehicles designed for off-roading in rough terrain. Yet another consideration was that the steel receivers were being produced by an offshore supplier.

Design opportunities

As originally designed for 2018-2021 Jeep Wranglers and Gladiators, there were three types of steel receivers, all roughly the same size but with different geometries and each with a left and right side version: There were two outboard and two inboard with strikers — both mounted to the front roof cross-member — and, for Jeep Freedom Panel hardtops molded in sheet molding compound (SMC), two additional rear receivers mounted to the rear roof cross-member.

Vehicles with soft tops use only the front outboard receivers while SMC Freedom Panel hardtops use all six receivers. The steel parts were powder coated for corrosion resistance, UV protection and appearance. In use, the brackets are permanently mounted to the vehicle; panels can be removed by actuating a release handle and can be reinstalled after re-engaging the handles.

Shown above on top left and bottom images, there are two outboard receivers (left and right side) and two inboard receivers with strikers (left and right sides) — both types are mounted on the front roof cross-member (bottom image closeup). For SMC Freedom Panel hardtops, two additional rear receivers (left and right side, not shown) are also used. Critical loads seen by each type of receiver are shown in the top right image. Photo Credit: Stellantis

The Jeep engineering team identified a series of critical loads that each type of receiver saw in use: X, Y and Z loads for the outboard, Z loads for the inboard and rear and asymmetrical loads for both inboard and outboard. To pass the full battery of CPN (Chrysler Part Number) validation testing, the CFRTP receivers would need to pass the same tests as the steel receivers, including accelerated weathering in wet/hot and dry/cold operating conditions, shaker tests to evaluate noise/vibration/harshness (NVH), color matching and the receivers had to demonstrate excellent dimensional stability/zero flexural creep to ensure good roof panel sealing. Additionally, no packaging or assembly line changes would be permitted; composite receivers would have to provide steel-like performance in the same package space and be assembled to the vehicle in the same manner.

Another requirement was that the composite receivers needed to visually match the benchmark steel components to ensure they were backwards compatible for service/aftermarket replacement. Hence, the candidate material would need to pass demanding mechanical requirements, be lightweight, provide a Class A weatherable surface and meet the OEM’s cost targets.

A collaborative team comprised of Jeep, MCAM and toolmaker Maple Mold Technologies (Auburn Hills, Mich., U.S.) began work on potential designs for the composite receivers. From a pool of five initial sets of designs for the various receivers, two went forward to be prototyped and tested, including production of four prototype tools by Maple Mold. The outboard prototype tool enabled multiple designs to be injected for testing. The more conservative of the two outboard designs featured a metallic insert in the composite while the other did not. Receiver designs were slightly modified to provide poka-yoke/error proofing so no left-hand versus right-hand side assembly errors could be made on the assembly line.

Significant consideration was paid to conducting a design of experiments (DOE) for materials selection. A total of 26 metal and composite options were initially evaluated — more than 15 of which were high-temperature polyamide (PA) options, either polyphthalamide (PPA) or PA9T. Both families are characterized by high resistance to heat, chemicals, humidity/moisture and abrasion while offering excellent dimensional stability and moldability. For each matrix, a number of FWF and fiber type and length options were evaluated, including USCF, short glass, long glass and long carbon fiber. Several different polymer/fiber options moved forward from virtual to physical prototyping in the two sets of designs. A final two composite material/design combinations advanced to vehicle validation testing just four months before kickoff.

All the performance at far less mass

The composite formulation with the best overall physical test performance was KyronMax S-4330, a new grade specifically developed for this application. The compound is 30% USCF/PPA. Interestingly, the all-composite roof receivers actually mechanically outperformed versions that featured a metal insert. Additionally, the 30% USCF/PPA also outperformed a 50% short glass as well as a 40% long carbon fiber PPA in key metrics. KyronMax compounds are said to mold like neat resin and offer isotropic properties (like metals) versus short or long fiber thermoplastics.

Despite the rigors of the injection molding process, fiber length is said to be retained and not be reduced further. Hot runners with direct valve gates on the production tools minimize gate vestiges. Additionally, the USCF compounds exit the mold with lower residual/internal stresses, thereby offering better knitline/weldline strength, reduced warpage for higher dimensional accuracy and better aesthetics.

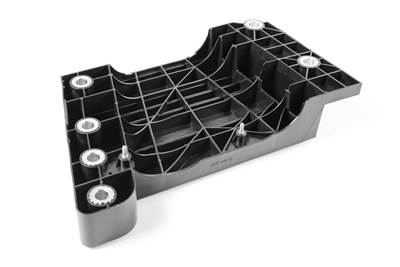

Shown above are the final three types of composite roof receivers as well as the pelletized ultrashort CFRTP injection molding material. Photo Credit: Mitsubishi Chemical Advanced Materials Inc.

The injection molded composite provided comparable part strength at 79% lower mass (for the six receiver/hardtop version) and 38% lower cost, while meeting or exceeding all Stellantis performance requirements for load deflection, torque and torque retention to the body-in-white, ensuring closure seal integrity. Additionally, scratch and mar were improved in a weatherable, molded-in-color (MIC) formulation that matched benchmark steel aesthetics with selective texturing on customer-visible surfaces. Finishing steps like sanding and powder coating were eliminated.

Switching from offshore-produced metal parts to onshore-produced composite parts shortened the supply chain and reduced energy requirements to ship relatively heavy parts over longer distances. Consequently, the composite receivers have a lower manufacturing and in-use carbon footprint than the benchmark steel parts (calculated as a CO2 reduction of 1,137 tonnes annually), helping support sustainability targets. This application is said to be the first high-volume structural CFRTP MIC and weatherable body application. A mid-cycle, running change was made to switch from steel to composite and start of production (SOP) was Feb. 26, 2021.

Related Content

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Riding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

Read MoreContinuous Composite Systems (CCS) – enhanced strength and rigidity

With our Continuous Composite Systems (CCS) products and process, L&L Products can deliver a cost-effective, lightweight, ultra-high strength reinforcement solution that brings extensive engineering knowledge, advanced CAE modeling, and the ability for adhesive use in a variety of applications. (Sponsored)

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)