Additive manufacturing: Metal vs. composites

3D printed metals seem to be moving into aerospace production at lightning speed. In reality, they face significant issues including standards and certification.

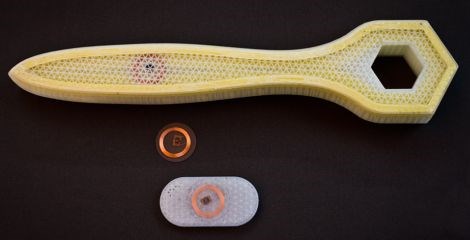

This Formula One racecar brake duct bracket is additively manufactured using nylon powder with short strand carbon fiber (e.g., milled fiber) and resembles some of the 3D printed metal brackets below. SOURCE: Graphite Additive Manufacturing.

I attended a CAMX 2014 education session on additive manufacturing (AM) last October, and though it primarily featured metals technologies, composites did enter the discussion. I was somewhat educated about AM with plastics and composites, but not so much with metals. I knew Airbus (Toulouse, France) was qualifying what it calls additive layer manufacturing (ALM) and that GE Aviation (Cincinnati, OH, US) was printing jet engine fuel nozzles, but that’s about it. I had the impression that AM metals were über materials, quickly taking over brackets in commercial airframes — a market where composites have made great inroads vs. traditional metals — and possibly eroding future opportunities for composites in aerospace and other industries. What I learned was that AM metals, just like composites, have applications where they fit and many where they don’t and, though they’ve been in serious development since the 1990s, still face significant issues with regard to cost of raw materials, standards (including best practices), certification and qualification.

A lightweight turbine cover door hinge for an Airbus A380, laser sintered from EOS Titanium Ti64 powder (lower right) may cut 10 kg per aircraft vs. conventional cast steel bracket (upper left). Source: castingssa.com and Airbus Group Innovations.

AM in Aerospace

According to a Nov 2014 article by Kathryn Creedy, Airbus has been 3D printing metal parts for three years, flying a seat belt buckle on an Air Transat A300 since February and a titanium bracket on an A350WXB — replacing aluminum and integrating 10 different parts for a 30% cost reduction — since June. Airbus’ Peter Sander says the company is aiming to print that part in series by 2016 and expects to print 30 tons of metal parts per month by 2018, aimed purely at replacing current milled components.

Airbus is qualifying ALM with a titanium airfoil demonstrator (foreground) and topology optimized A380 bracket made from stainless steel powder (midground) which offers cost and weight savings vs. the conventional bracket behind. SOURCE: Airbus.

GE’s fuel nozzle for the LEAP engine is the first AM part to fly in the hot section of a jet engine. It reduces part count from 18 to 1, and also the number of brazes and welds, drops weight by 25%, cost by 30% and reportedly increases durability by a factor of 5. The nozzle has been in flight tests since last fall, and with 19 per LEAP engine, GE estimates it will build over 100,000 AM parts for the LEAP and GE9X engines.

In 2013, GE and GrabCAD held an open 3D-printing challenge to redesign a

jet engine bracket. The winner was able to reduce the bracket weight 84%

from 2,033g to just 327g. SOURCE: GE Reports.

Advanced Manufacturing insight’s review of the Additive/Aerospace Summit 2014 (Nov. 3-6, Los Angeles, CA, US) gives a concise overview of players, trends and issues, with the latter an echo of what I learned at CAMX.

Promises vs. reality

AM metal structures are oft cited as producing no waste. Compared to subtractive manufacturing, waste reduction should be dramatic, but apparently not for every single application. Steven Woods, senior project manager at GE Power & Water gave an example of using 40 lb of powder to make a 10 lb part and then explained the challenge of how to reclaim that 30 lb and certify that it is good to reuse? He noted that GE will mandate that issue be solved, because at $50/lb for some of these materials, that loss cannot be tolerated. Woods noted there is no “closed loop” AM metals process yet.

This also highlights the issue of standards. How does a company recertify AM powders? What are the best practices for housing the machines and keeping them clean? What are the best practices for production? What do you do if there is a power glitch? Do you just throw away the part? GE has looked at a whole range of solutions for ensuring backup power during production, but there are many solutions possible. GE is developing its own standards for certification, for example, because they have no choice. The industry simply isn’t there yet.

AM metal parts are also touted as providing a way to produce very complex parts in less time. Again, while that definitely is true for a number of parts, Woods indicated that production of the LEAP fuel nozzle still requires 22 steps. Part of this is due to the porous nature of the printed metal part, requiring subsequent heating, chemical and coating operations, while part is because AM is less accurate than machining, so that additional finishing steps are required.

There is also a tremendous amount of process control and inspection technology that remains to be developed. One review of metal AM noted that microstructure and mechanical property anisotropy are ubiquitous with the z-direction being the weakest in general. Prabhjot Singh, manager of GE’s Additive Manufacturing Lab observed in 2011: “[An AM] part is made out of thousands of layers, and each layer is a potential failure mode. We still don't understand why a part comes out slightly differently on one machine than it does on another, or even on the same machine on a different day."

Reportedly, GE has spent over 15 years building databases of process knowledge, characterizing parameters and sensitivities, and qualifying each machine. But it makes sense that its first AM engine part into production is an application where a few out of the 19 actually failing would not be catastrophic.

The LEAP fuel nozzle also shows where AM makes the most sense: low volume, complex parts that are hard to produce by conventional means and where 3D printing eliminates costly tooling. Well, LEAP is not exactly a low volume program, hence GE’s reported $50 million investment into its Auburn, Alabama facility, including 300 personnel and an initial 10 printers which could potentially grow to 50.

In addition to the issues discussed above, a near-term development wish list for AM includes: “first part correct”, multi-material integration, process robustness built into equipment, surface finish and speed.

The Mark One now allows users to easily embed electronics, sensors, ball bearings, hard mounting points and more into 3D printed parts made with carbon, glass and/or KEVLAR fiber. SOURCE: MarkForged.

Composites

Composites entered the discussion via Dr. Michael Ohadi, professor of Mechanical Engineering at the University of Maryland (College Park, MD, US), who holds numerous patents and is internationally recognized for his research in heat and mass transfer and smart energy systems. He sees AM enabling radically new heat/mass exchanger designs using polymers, metals and composites that have the potential to double the coefficient of performance (COP), and thus drastically reduce, or even eliminate, cooling water consumption. He explains that composites offer unlimited potential in AM because you can essentially create the precise material you need. When designing heat exchangers with fins twice the thickness of human hair (to achieve huge increases in surface area) the ability to design materials on a micro- and nano- scale becomes revolutionary and AM falls in line as the enabling manufacturing process.

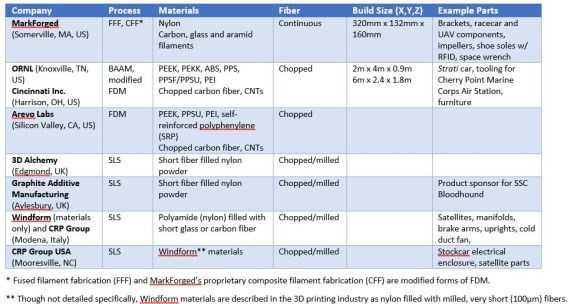

Composites in AM is definitely growing, in the number of companies involved, the material properties possible thanks to continuous filaments and in the size of parts possible. The latter was demonstrated at the 2014 IMTS show (Sep 8-13, Chicago, IL, US) with the printing of the carbon fiber reinforced plastic carStrati using big area additive manufacturing (BAAM) by Local Motors (Chandler, AZ, US), Oak Ridge National Laboratory (ORNL, Knoxville, TN, US) and Cincinnati Incorporated (Harrison, OH, US). (Watch for CW’s exposé on the project and its evolving technology in March 2015). Below is a table listing some of the players and technologies to date.

I have a much better understanding now of where AM metals stand and where they are headed. They are über materials, and do represent a competitive technology. But they are also a nascent technology still requiring a lot of development, and currently aimed squarely at low volume, extremely complex parts and those traditionally made from machined metals. AM also offers significant potential for composites, albeit perhaps using less fiber and shorter fiber formats. Rest assured, CW will continue to watch the trends and share what we find with our readers.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)