PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

This is a follow-up to the recent series of articles on thermoplastic composites (TPC) that I have written plus the thermoplastic tapes feature Jeff Sloan wrote in the February 2018 issue.

TPC materials have been flying on aircraft since the 1990s and in primary structure since 2010 — Gulfstream’s G650 features a carbon fiber/polyphenylene sulfide (PPS) rudder and elevator produced by GKN Aerospace’s (Solihull, U.K.) aerostructures business GKN Fokker (Hoogeveen, Netherlands) using Cetex prepreg supplied by Toray Advanced Composites (TAC, previously TenCate Advanced Composites, Nijverdal, Netherlands). Since that time, much work has been done to prove out polyetherketoneketone (PEKK) and polyetheretherketone (PEEK) materials. And low-melt polyaryletherketone (LMPAEK) is now another option.

I think sometimes we forget how much experience we have in TPC technology already (see CW’s thermoplastic composites page). In the past, we have asked “why aren’t more TPCs flying on aircraft?”. Perhaps now, with Boeing’s preparation for the New Mid-market Airplane (NMA) and the European aircraft industry’s progress via Clean Sky 2 and other development programs, we may finally see a new round of applications enter service.

In the meantime, there is an extensive supply chain already established with an array of veteran companies, including TAC (also based in Morgan Hills, Calif., U.S.), Teijin Carbon Europe (Wuppertal, Germany) and Solvay (Alpharetta, Ga., U.S.). Each has a different view as to which polymers and processing technologies offer potential.

Toray Advanced Composites — TPC veteran continues advancing technology

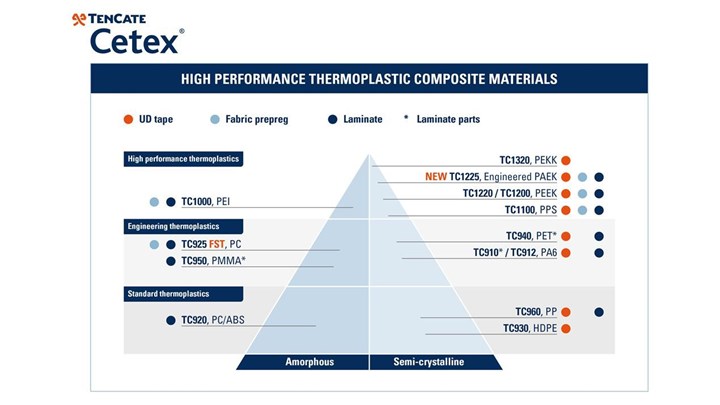

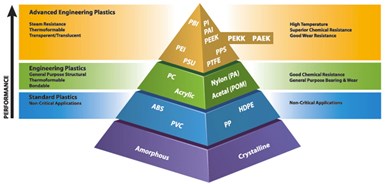

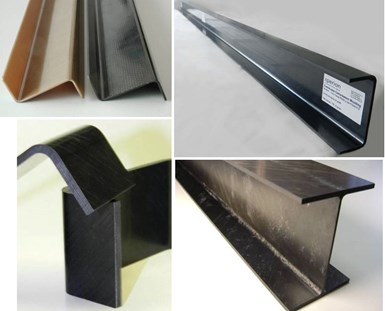

Cetex thermoplastic tapes are available in a wide variety of matrix polymers from lower melt temperature/performance to higher melt temperature/performance. Photo Credit: TAC (top), Tri-Mack Plastics (bottom) with PEEK, PAEK added by CW.

Through its acquisition of TenCate Advanced Composites in 2018, TAC claims more than 40 years of experience in developing thermoplastic composites. Its Cetex brand is well known for prepreg and preconsolidated laminates (also called organosheet) but also extends to bulk molding compound (BMC) as well as unidirectional (UD) and woven tapes. The company has a long track record with the complete range of thermoplastics (see graphic below). These materials are used in applications supported by TenCate’s Aerospace and Industrial divisions, as well as more mass market products like consumer electronics and athletic shoes via the company’s Performance Composites division.

During the interviews for my series on in-situ consolidated TPC, low-melt PAEK (LMPAEK) polymer developed by Victrex (Clevelys, U.K.) came up as a potential alternative to PEEK and PEKK in the quest for faster processing. When I asked TenCate about this, Dr. Hans Luinge, director of thermoplastic composites research & product development for TenCate, recapped the difference in melt temperatures:

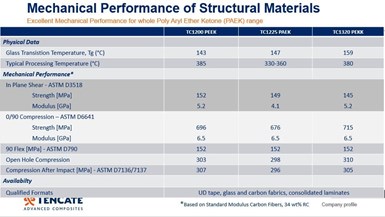

- TC1225 Carbon fiber (CF)/LMPAEK tape 305°C

- TC1320 CF/PEKK tape 340°C

- TC1200 CF/PEEK tape 350°C

Note that actual temperatures used when processing these composite tapes may be higher, but TC1225 LMPAEK is still attractive due to its much lower melt point.

“Cetex TC1225 LMPAEK was introduced in the TAPAS1 development program, in which we were a key participant,” Luinge recalls. He points out that by 2013, the TC1225 material had already been used in a demonstration aircraft structure. Airbus Nantes exhibited a fuselage panel with integrated stiffeners at the 2013 Paris Air Show. It was fabricated using the CF/LMPAEK tape supplied by TenCate, with press-formed omega and butt-jointed T stringer elements that were welded to the skin, made with automated fiber placement (AFP).

“LMPAEK works well in AFP, stamp forming and welding,” says Scott Unger, TenCate global chief technology officer. But with the lower melt temperature, aren’t the mechanical properties for LMPAEK lower than PEKK and PEEK? Unger says no, they are all roughly the same. “PEEK, PEKK and LMPAEK are all good structural materials, and from a cost perspective, TC1225 is priced competitively with TC1200 CF/PEEK and is lest costly than TC1320 PEKK.”

Low-melt PAEK speeds up in-situ consolidation

Furthermore, TC1225 LMPAEK holds promise for in-situ consolidation, which Unger concedes “is potentially the Holy Grail. But what we’ve seen in the past is that your AFP speeds must be very slow in order to achieve in-situ consolidation.” He explains, “You can’t get to in-situ consolidation without using a tape that demonstrates a much lower void level than what is ultimately acceptable in the final laminate or structure. There are two key factors: tape quality and how well the matrix resin and fiber are distributed in the UD tape.” Unger claims TenCate’s UD tape manufacturing processes have been designed to produce extremely low void levels to enable processes like rapid AFP followed by out of autoclave/vacuum bag only (OOA/VBO) consolidation as well as one-step, in-situ consolidated AFP.

“Our tape is extremely consistent with 0 to 0.5% voids maximum,” says Winand Kok, TenCate director of expert services EU. “Our tape thickness is also very consistent, which is why we can achieve very accurate ply thicknesses in consolidated laminates. This consistency is also important for thermoplastic welding processes and in-situ consolidation.” Unger comes back to the second requirement he outlined above: “LMPAEK has much better flow versus PEKK and PEEK. It also can be processed at higher speeds than PEKK and PEEK.”

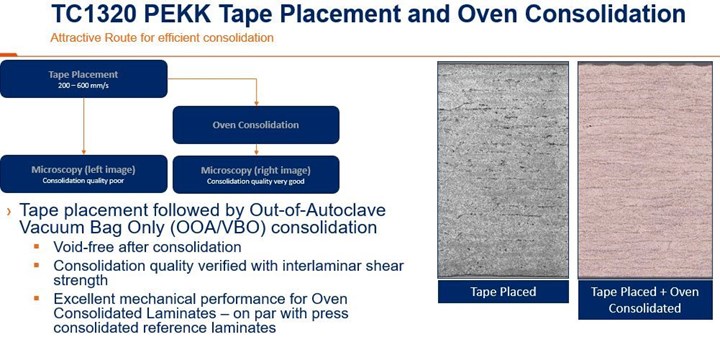

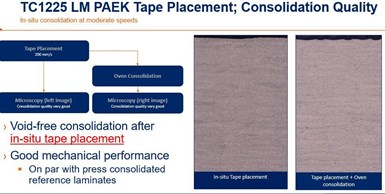

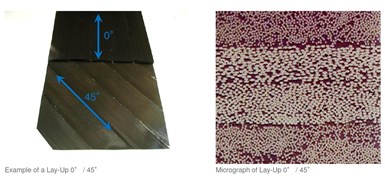

CF/PAEK made with AFP in-situ consolidation (no secondary step) showed the same consolidation properties as CF/PEKK made with rapid AFP + consolidation in oven (top). Photo Credit: Toray Advanced Composites

This last point was demonstrated in a laminate-to-laminate comparison. “We made TC1320 CF/PEKK laminates using a Coriolis laser AFP machine at the ThermoPlastic composites Research Center (TPRC) in Twente, The Netherlands,” says Unger, “at a rapid speed of 600 mm/s. We then consolidated this laminate using vacuum bag only in an oven.” He acknowledged there was porosity in between the plies due to the rapid AFP layup, but these voids were remediated during the second consolidation step, illustrated in the photo micrographs of the laminate. “We also fiber placed the TC1320 material at 200 mm/s and found that the porosity between the plies was not eliminated with the slower speed. We then made an equivalent laminate using the same AFP machine but this time using TC1225 CF/LMPAEK tape without any secondary OOA/VBO consolidation step — i.e., full in-situ consolidation via AFP. We achieved the same consolidation properties as in the PEKK 2-step panel.”

Unger notes the AFP speed of 200 mm/s for the in-situ consolidated CF/PAEK laminate is more than twice that claimed by Henri de Vries, senior scientist, composites, in the Structures Technology Dept. at the Netherlands Aerospace Centre (NLR, Amsterdam), in my article, “Consolidating thermoplastic composite aerostructures in place, Part 2”:

De Vries agrees, noting there is still a noticeable gap between ISC AFP rates and processes in which consolidation is completed in a second step. “We can lay at 60-100 mm/sec for in-situ-consolidated thermoplastic composites, but if we lay as fast as possible and then post-autoclave, the speed is 600-700 mm/sec.”

“Now, we’re looking at how far we can push the in-situ consolidation AFP speed while maintaining acceptable void levels and mechanical properties within the laminate,” says Unger. “We’ve done a lot of work on laying a stiffened TPC panel using automated processes. Now the goal is to build the technology readiness level.” Kok says TAC continues to do this, working with industry partners, including customers and R&D institutes.”

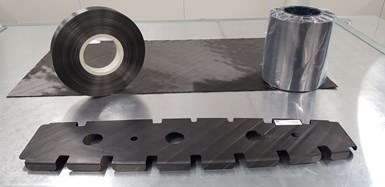

Slit CF/PEKK tape and laminate made using automated tape laying and a press-formed rib produced by DTC. Photo Credit: DTC

“One example,” he continues, “was the engine pylon made using TC1320 CF/PEKK tape on display in our stand at JEC 2018. We worked with both the pylon shell fabricator, NLR, as well as Dutch Thermoplastic Components (DTC, Almere), which press-formed ribs that were welded to the shell as stiffening elements. Though this part was made using AFP and then consolidated in an autoclave, Kok notes, “We are also exploring how to further optimize tapes for 2-step consolidation using only vacuum bagging in an oven instead of an autoclave.”

Unger notes that unsized carbon fiber as well as carbon fiber with sizing are used in TenCate’s CF/LMPAEK products for demonstration of primary aircraft structures. He says that although five years ago it may have been uncommon to see LMPAEK, PEKK and PEEK prepreg tapes that used carbon fiber with sizing because of adverse effects on the mechanical properties associated with the sizings, that certainly is no longer the case today.

One last point stressing the potential of LMPAEK is that NIAR and the FAA are in the process of completing the first public database for a thermoplastic composite material, using TenCate’s TC1225 CF/LMPAEK. The database is to be released early next year, and this material was chosen because of its mechanical properties and ease of processing.

Teijin — Longtime CF producer moves into TPCs

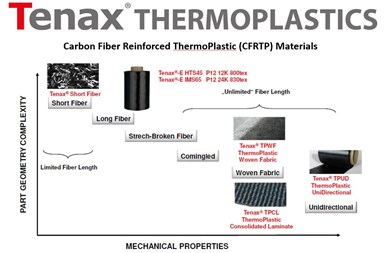

The carbon fiber (CF) producer previously known as Toho Tenax Co. Ltd. (Tokyo, Japan) is now rebranded globally as Teijin Carbon, with Tenax Thermoplastic tape production in Heinsberg, Germany.

“We spent a lot of time developing thermoplastics 15-20 years ago,” says Jean-Philippe Canart, previously thermoplastic semi-products product manager for Toho Tenax Europe and now aerospace market engineer for Teijin Carbon America. “One of our strategies was to develop unidirectional (UD) thermoplastic tape, which we introduced in 2013.”

Canart explains the building blocks for this development, “One of our core technologies is thermoplastic sizing for CF, which helps with tape processing. Standard CF sizing must be removed due to the high processing temperatures required for thermoplastics. In addition to temperature resistance, thermoplastic sizing also gives extra performance with fiber-to-matrix adhesion in the finished composite. One of our biggest lines in Europe produces 1,700 tonnes/yr of CF equipped with TP sizing. From here we developed UD tape with PEEK, PEKK and PPS thermoplastic matrices for use mostly in aerospace applications but we are also working on oil & gas and industrial applications.”

Canart says that Teijin’s first focus with TPC was on press forming (stamping) of clips and brackets for the Airbus A350, using CF fabric coated with PEEK: “This was the first big wave of aerospace applications. We see this now moving to larger, more structural parts produced with a mix of AFP laminates followed by consolidation via stamping.” Canart acknowledges that in-situ consolidation (ISC) has been in development for decades, but contends, “we don’t see it as mature yet. We are supporting R&D projects and institutes in further development.” He says ISC is possible, “but the question is how quick can you make parts? And how robust is the process?” He believes it will be 2025-2030 before ISC parts are in production for commercial airframes. In the meantime, Teijin sees expansion in TPC tapes for 2-step, AFP + stamping production lines. “We have already invested in our European tape line and are also supporting new process capacity like continuous compression molding (CCM). The supply chain is growing.”

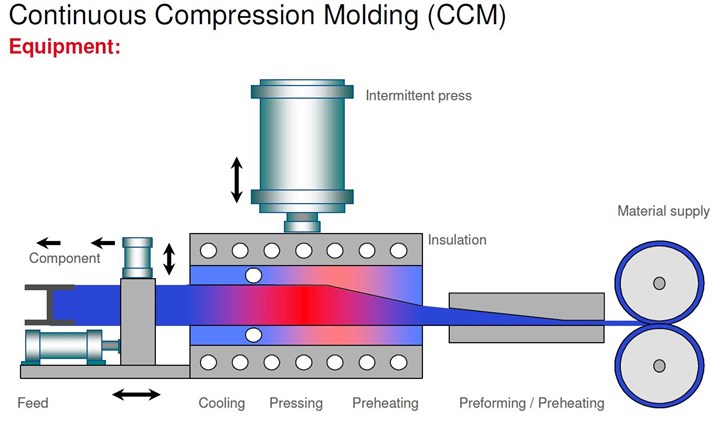

Supporting TPC mass production — CCM

Continuous Compression Molding (CCM) is a process that I wrote about in 2010: “Aerospace-grade compression molding”. It is trademarked as X-CCM by xperion (Markdorf, Germany), the company that initially developed and commercialized the process over two decades ago. X-CCM offers high-quality thermoplastic composite laminates using a fast, quasi-continuous process. “We are working with xperion as a materials supplier,” says Canart. “This is a mature technology, used for many years by both Airbus and Boeing. Now it’s really growing, used to produce shaped consolidated laminates. CCM is great for cost but the cross-section needs to remain constant.”

Teijin is supporting growth in TPC tape-based parts manufacturing processes like continuous compression molding (CCM). Photo Credit: Teijin, SAMPE Seattle 2014.

According to Laurens de la Ossa, senior sales manager for xperion, “Our X-CCM process is more advanced now, capable of producing more complex shapes, including asymmetric profiles like T- and J-profiles.” He adds that the process can produce consolidated TPC laminates up to 24 inches in width. “We are part of a whole technology infrastructure that is moving toward mass production of thermoplastic composites. We have a very sleek process for consolidated TPC parts — there is no vacuum bagging, and we can handle thick laminates of 60 plies and beyond, 8-10 mm in thickness.”

What kind of parts does X-CCM target? “Interior fuselage stringers, floor beams and other framework around the floor or ceiling, structural components and semi-structural applications which demand the highest material performance,” says de la Ossa. “By 2025, when the new aircraft platforms start to enter production, we will hit 6-10 times the volume of material annually just to provide what we have responded to with quotations to date.”

As part of this continued push toward higher volume production, Teijin is focused on reducing tape material cost and increasing capacity, says Canart. What about the industry’s requests for thicker tape? Specifically, de Vries at NLR had said:

standard material is .13mm thick but tapes up to .18mm thick are being explored in the TAPAS2 program. Ideally, de Vries would go even further: “We would like to go to .25 mm thick in both PEEK and PEKK, but it’s hard to get high-quality.”

“We have already developed tape with fiber areal weight ranging from 145 to 200 g/m2,” Canart replies. “With these products, a thickness of .18mm is already quite standard for us. We have modified our lines for this thickness and also up to .20 mm, so I think 0.25 mm even would not be a big jump.”

Airbus A350 fuselage clips were made using PPS and PEEK composites. Cetex CF/PPS laminates used woven T300 carbon fiber from Toray and Tenax TPCL laminates were based on its TPWF thermoplastic woven fabric products. Photo Credit: Teijin, Premium Aerotec Group

And what about tape quality? “We think all tape needs to be modified for higher-quality parts at faster speeds,” says Canart. “The resin content may not match what in-situ consolidation requires and the distribution of the resin within the tape may need to be optimized as well. The time and speed of melting is so different for the different resins and processes. We are supporting further development in a variety of areas, including the polymer systems and the architecture of the tape, including the surface.”

Solvay — market for both PEEK and PEKK

Solvay’s high-performance thermoplastic products for composites include Ketaspire PEEK, Novaspire PEKK, Radel Polyphenylsulfone (PPSU), and Ryton Polyphenylene sulfide (PPS). In a statement submitted by Solvay, the company asserts that these polymers are produced at industrial scales that will allow consideration for large-volume aerospace composite applications and can be used to produce high-quality prepreg.

Thermoplastic composite horizontal tail demonstrator manufactured by GKN Fokker using Solvay APC(PEKK-FC)/AS4D. Photo Credit: GKN Fokker.

Solvay currently provides APC unitape prepregs with both PEEK and PEKK polymers, with pricing primarily differentiated by the cost of the selected fiber rather than the polymer when produced and used at high volumes. Therefore, it believes that selection of which thermoplastic matrix to use for a given application will be driven by customer preference. Factors affecting that choice include temperature performance, mechanical performance, part fabrication processing, material database availability and workforce experience, to name a few. Solvay’s view is that both PEKK and PEEK serve a need in the marketplace and that it is able to offer high-quality, comparatively priced fiber-reinforced prepregs independently of which polymer is selected.

So for thermoplastics, as in all other composites, the choices in materials and processes are not limited. In fact, they seem to be expanding. Which will gain ascendancy in future aircraft production? That remains to be seen. CW will keep watching and reporting what we see.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More