Antiballistic composites: Course corrections

Changes in the military theater are rewriting the script for composites in ballistic protection applications.

Earlier this year, HPC reviewed composites trends in the antiballistics arena (see “Antiballistic: Better defense, less expense," under "Editor's Picks," at top right). Much has changed since then. Military presence on the ground in Afghanistan has plateaued and, in Iraq, is winding down. The demand for new vehicle armor, therefore, is tailing off and once prodigious output of new antiballistic solutions from R&D programs has slowed. Armorers, however, are adjusting and supplier adaptability is ensuring that composite technologies will continue to find a place in this still opportunity-rich market segment.

Composite-armored spare parts

For vehicles, the most common use of composites, to date, is in add-on armor panels and spall liners, which are attached to a steel or aluminum base structure to provide additional ballistic protection. And although there has been some successful R&D for all-composite armored vehicle solutions, in the current market a realistic next step for composite growth in armored vehicles could be replacement parts for key steel components in fielded vehicles.

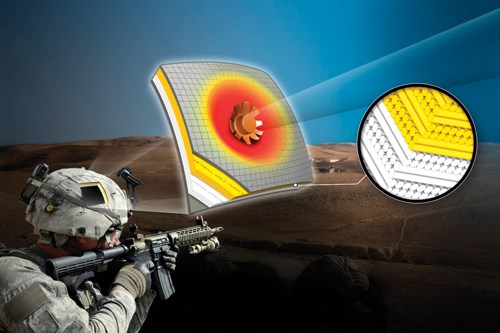

“Modern vehicle armor must defeat armor-piercing projectiles that typically contain a pointed steel or tungsten core of remarkable hardness,” explains Paul Bourke, head of R&D at TenCate Advanced Armour (Almelo, The Netherlands). “To achieve protection in steel would require slabs of armor close to 50 mm [2 inches] in thickness,” he adds, which is why composites have been so successful in the add-on market.

Yet the weight of the steel structure plus the add-on composite panel and any necessary integration components or hardware can present a real challenge to armored vehicle platforms already groaning under the weight of many other additional systems designed for modern, asymmetric warfare, he adds.

As an alternative, TenCate has developed a 3-D molding method for its patented Liba armor system, designed to not only replace but improve upon existing steel components. “In the same way as composites entered the aerospace sector, TenCate is initially targeting small components to build market confidence,” explains Bourke. “Hatches, doors, access panels and bonnets are all examples of steel components that can easily be removed and replaced.”

“Often we are able to increase the level of protection significantly while still reducing weight over a steel component,” Bourke reports, citing a recent 3-D structural armor hatch that measures ~0.7m2/~7.5 ft2 at a weight savings of more than 40 kg/88 lb compared to add-on armor of a similar protection level.

Further, Bourke claims, “it is possible to take a steel component designed to protect against a handheld rifle and replace it with a composite component of equivalent or less weight that can protect against heavy machine gun fire.”

“The major challenge ... was ensuring the properties of the structure did not adversely affect the ballistic performance,” explains Bourke. “In many cases, these materials are optimized for ballistic resistance, which results in poor stiffness, low interlaminar strength and challenging bonding behavior.”

TenCate’s process, therefore, begins with layup of a structural outer skin, which could comprise glass fiber-reinforced high-performance epoxy, carbon fiber-reinforced epoxy or custom-weaved carbon/aramid hybrid fabrics and epoxy resin, depending on the application. This is followed by the layup of the Liba ceramic into a 3-D shape, the structural confinement layer that holds the ceramic in place and the 3-D shaped, no-cut aramid backing layer. During final assembly the inner skin is added and structural inserts are installed. TenCate’s Rosist coating protects the composite from environmental attack, UV degradation and impact damage from rough handling.

Accurate fiber placement is the key that enables engineers to duplicate, in the composite parts, the rigidity of the steel components they will replace, stresses Bourke. “We ensured there were no ballistic weak points in the design by constantly seeking to achieve the correct weave architecture and avoiding cuts. Every time a gap or overlap has to be reinforced it adds to the parasitic weight that we are trying so hard to avoid in the first place.”

One prototype is undergoing field tests by a customer/partner. Lessons learned will inform the design and manufacture of the production-ready product.

Composite blast chimney

Hardwire LLC (Pocomoke City, Md.) has developed and demonstrated a vehicle blast protection system that uses Dyneema HB26 and HB50 ultrahigh molecular weight polyethylene (UHMWPE) fiber from DSM Dyneema (Geleen, The Netherlands). Central to the approach is the Structural Blast Chimney (SBC), designed to protect occupants of light military vehicles from improvised explosive devices (IEDs).

The SBC channels energy from an explosion under the vehicle toward the center and then up through the chimney, not only shielding the soldiers from the blast, but also acting as a pressure release, allowing the vehicle to stay on the road. A structural component, the chimney also connects the vehicle’s heavily reinforced floor to its roof, resulting in a more rigid cab structure.

Blast tests conducted at the Army’s Aberdeen Test Center in Aberdeen, Md., reportedly demonstrate that an SBC-equipped Humvee (at a gross weight of 16,300 lb/7,394 kg) could provide a survivability level comparable to the M-ATV, which, at roughly 30,000 lb/13,608 kg, is the lightest version of the military’s mine-resistant, ambush-protected (MRAP) vehicle.

Building a better combat helmet

Military withdrawals notwithstanding, R&D work toward lighter but more ballistic-resistant combat helmets is yielding production contracts. The U.S. Army’s Program Executive Office (PEO) Soldier, a government entity responsible for the development, procurement and fielding of equipment for Army personnel, has awarded Honeywell Advanced Fibers and Composites (Colonial Heights, Va.) a three-year contract to provide its Spectra Shield and Gold Shield materials for evaluation in next-gen combat helmets.

“Under the contract we have with PEO Soldier, we’re looking to further reduce the weight and improve the capabilities of the enhanced combat helmet [ECH] through the development of new Spectra Shield materials,” says James Thagard, Honeywell’s global marketing manager/helmets. Honeywell also is focusing on developing hybrids of its Spectra Shield UHMWPE and the Gold Shield aramid materials that would better balance the ballistic and nonballistic performance of a new helmet, says Thagard. “Our goal is to take weight out ... while maintaining or improving on ballistic capability.”

Reportedly able to stop 7.62-mm rifle rounds, the Honeywell version of the ECH is undergoing field tests this fall. Prototype testing suggests ballistic improvement of more than 35 percent over the helmet currently in the field. The Army is expected to order 200,000 ECH helmets.

“During the ECH development, the curved shape ... was the biggest challenge,” says Thagard. “Using new technologies, such as slitless preforms, manufacturers are able to form the shape ... without cutting slits in or seaming the material,” he adds. “The ability to maintain a continuous reinforcement allows for higher ballistic performance in the helmet configuration.”

Related Content

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreRead Next

Future combat helmet: Promising prototype

Tape laying, thermoforming methods hold hope for rapid coforming of thermoplastic shell and ballistic liner for U.S. Army’s future warfighter headgear.

Read MoreAntiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)