Antiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Ongoing concerns about threats to infrastructure security are contributing to the growth of new markets and applications for armor and other antiballistic materials. In an attempt to maximize performance yet minimize cost, suppliers and manufacturers of these products are increasingly turning to designs that integrate not only a variety of materials, such as ceramics and steel and composite laminates, in a single armor solution, but also are making use of multiple reinforcement forms in composites by combining carbon, aramid, glass and other fibers in preforms and prepregs. These hybrid composites take advantage of the unique benefits offered by each material. Armor manufacturers also are taking full advantage of developments in nanotechnology to improve the performance of composite matrices. HPC canvassed the growing antiballistics community and found a number of recent product developments that illustrate the trends.

CNTs enhance z-integrity

Riley Solutions Inc. and NanoRidge Materials Inc., both located in Houston, Texas, have joined forces to launch what may be the first commercial armor application built with carbon nanotube-reinforced composites. The carbon nanotubes (CNTs), supplied by NanoRidge, are dispersed into ceramic-fiber fabrics in a reaction vessel under heat and pressure. The CNTs attach to the fibers, creating a linkage between individual layers of fabric, which in turn imparts strength in the z-direction. The laminate fabric is infused in a heat press or autoclave with either an epoxy or urethane resin that contains additional carbon nanotubes. As a direct result of the use of nanotubes, the panels, which can be made to any length or thickness, reportedly have improved strength-to-weight ratio and enhanced backface deformation properties. John Tidrow, president of Riley Solutions, says the proprietary process and materials have been in development for years. In addition to ceramic fiber, supplied by Superior Technical Ceramics (St. Albans, Vt.) a variety of other fibers are used in these panels, including aramid fiber, and a high-molecular-weight polyethylene (HMWPE) fiber from DSM Dyneema (Geleen, The Netherlands), “The process of making cost-effective carbon nanotube-reinforced armor involves tweaking every individual component of a composite, from the fibers to fabric to the resin,” he says.

Riley Solutions opened a new manufacturing facility in January, and Tidrow says the first commercial application will be panels for a military aircraft. The panels will provide antiballistic protection on the flight deck and other sensitive areas that are susceptible to small arms fire when the aircraft takes off or lands. The fabric can be cut to shape, enabling the company to easily customize panel dimensions. One panel, for example, is 3 inches/76.2 mm thick at one end, 7 inches/177.8 mm thick at the other end and only 10 inches/254 mm in length. Tidrow says the company also is working with a major armor manufacturer to commercialize lightweight, nanotube-reinforced composite body-armor insert panels.

Adapting E-glass for antiballistics

Historically, antiballistic material designers have preferred tough but expensive aramids, high-density polyethylenes and the like, passing over conventional E-glass as too brittle to have ballistic stopping power. But Waco Composites Ltd. (Waco, Texas) now manufactures bullet-resistant fiberglass panels, sold under the trade name ArmorCore. The panels are designed to provide firearm-resistant ballistic protection specified by eight of the nine levels of the Underwriters Laboratories’ (UL) Standard of Safety for Bullet-Resisting Equipment, UL 752 (see Table 1, p. 40). Company president Wayne Hampton says the panels are made with an E-glass woven roving infused with “proprietary additives, fillers and a resin system that enhances performance.” The panels are sold in several sizes, the most common being 4 ft by 8 ft (1.2m by 2.4m), and in thicknesses ranging from 0.25 inch/6.35 mm, which satisfies Level 1 requirements, to 1.4375 inches/36.51 mm for Level 8 protection. The panels are pressed and shaped in a heated platen in a process similar to that used to make plywood.

Founded in 1995, Waco Composites initially entered the market with ArmorCore panels that meet standards for UL 752 Levels 1 through 4. The product line was primarily targeted to federal, state and local judiciary buildings, following a government mandate that all judges’ benches be built with bullet-resistant materials. Although the benches remain one of the core markets for the company’s panels, Hampton reports that, over the past five years, the company has seen 10 percent growth per year in sales of panels used in wall-armor applications for high-level building security, residential safe rooms, tornado shelters and other structures. Notably, a safe room helped protect the crew of a British-flagged tanker, thwarting a hijacking attempt by Somali pirates in the Arabian Sea in January of this year.

“We had some of our Level 3 [0.4375-inch/11.1 mm thick] panels installed in the interior walls of the Pentagon when the jet crashed into that wing on 9/11,” notes Hampton. “After the crash, it was determined that the panels helped limit the damage.” Since that time, the company has supplied panels used to armor interior and exterior walls of the entire Pentagon, as well as numerous U.S. federal buildings, including those occupied by the Department of Treasury, the Federal Bureau of Investigation and the Central Intelligence Agency, says Hampton. Exterior walls are reinforced with panels that meet UL 752 Level 4 (1.375 inches/34.9 mm), Level 5 (1.5 inches/38.1 mm) or Level 8 (1.4375 inches/36.5 mm). The panels are most commonly installed as structural wall boards and then covered with drywall for interior walls or faced brick or other cladding materials for exterior walls. Hampton says the company also is supplying armor kits to military branches to up-armor combat vehicles, helicopters and naval vessels. “In the last seven years we have helped up-armor 3,500 Humvees,” he reports.

Hampton says Waco Composites is supplying ArmorCore panels to act as spall liners in the construction of an armor system capable of providing protection against .50-caliber armor-piercing rounds. DefBar Systems LLC (Lebanon, Mo.) manufactures and markets the .50-caliber-resistant product as part of its trademarked Zouline family of opaque armor, designed for vehicle, architectural and aviation applications. The armor system combines parabola-shaped ceramic strike-face tiles with 2.5-inch/63.5-mm thick ArmorCore panels that weigh approximately 29.5 lb/ft2. When a projectile strikes the parabola-shaped ceramic tiles, it is deflected away from the target and its energy is dissipated.

Elsewhere, Fiber-Tech Industries Inc. (Washington Court House, Ohio) is planning to launch an antiballistic-grade panel designed to meet UL 752 Levels 1 and 2 sometime this year. If the testing is successful, the new product will be targeted for ballistic protection of commercial buildings, such as those that house banks and courtrooms, according to Terry Keegan, president of Fiber-Tech. Keegan says the panels will be made of woven E-glass and a thermoset resin. The product represents the company’s second attempt to enter the antiballistics market. “In 2008 we qualified some ballistic-grade panels, but the product is at a price point too high for today’s market,” Keegan says. “This time we plan to qualify a more competitive product.” The company also manufactures fiberglass-reinforced panels for the transportation, construction and agricultural markets. The company uses E-glass produced by Owens Corning Composite Materials (Toledo, Ohio) and PPG Industries (Pittsburgh, Pa.)

3-D weaving expands armor apps

Historically, 3-D weaving has been used to make thick, complex preforms that, when infused with resin, produce robust, high-strength parts for aerospace, military and other industries that demand high performance. Yet these same characteristics and properties also make 3-D preforms suitable for cost-effective production of panels and components destined for heavy-duty armor applications.

T.E.A.M. Inc. (Textile Engineering and Manufacturing, Woonsocket, R.I.) employs a customized jacquard loom to manufacture net-shaped, woven-fabric polymer matrix composite (PMC) preforms from glass, carbon and other fibers in thicknesses ranging from 0.25 inch to 2 inches (6.35 mm to 50.1 mm). The PMC preforms are generally infused with polyester resin by a conventional vacuum-assisted resin transfer molding (VARTM) process. Aaron Tomich, T.E.A.M. Inc.’s program manager, says that making similar preforms by traditional methods would require laminating 40 or more plies of fabric, and the resulting 2-D multi-ply laminate would have inherently inferior multihit ballistic performance compared to 3-D woven preforms. “From a structural point of view, the woven preforms we produce have fibers oriented in the x, y and z planes, which imparts excellent ballistic properties that prevent that structure from delaminating upon impact,” says Tomich. “The superior multihit performance of 3-D woven preforms compared to 2-D laminates is quite clear.” T.E.A.M. uses S-2 Glass from AGY (Aiken, S.C.) and carbon fiber supplied by Hexcel (Dublin, Calif.). The company also manufactures preforms from 3M’s (St. Paul, Minn.) Nextel high-temperature ceramic fiber. The ceramic preforms are then infused with molten metal to create a metal matrix composite (MMC) that serves as an armor backface.

According to Tomich, T.E.A.M. Inc. is supplying PMC hybrid (multifiber) and single-fiber preforms, as well as MMC preforms, to the U.S. Army to evaluate armoring “several new tank-like vehicle platforms.” The project is part of the Army’s initiative to lighten and reduce the cost of next-generation armor solutions, and hybrid preforms are helping on both fronts. The company’s customized loom facilitates rapid, cost-effective production of hybrid preforms via computer control of up to 7,000 independent warp fibers at once. Independent control of fibers, in turn, gives designers the freedom to mix and match fiber types to achieve the desired antiballistic performance at a lower cost.

For example, T.E.A.M. manufactures a 1-inch/25.4-mm thick preform consisting of 10 percent carbon fiber and 90 percent S-glass by volume, a design that optimizes cost and weight compared to a preform of identical thickness made entirely of S-glass (see inset image, p. 38). Further, Tomich says the company is looking at ways to substitute E-glass for S-glass in a hybrid preform design. E-glass is one-tenth the cost of S-glass, and it exhibits less strength and stiffness. This lack, however, could be offset by nominal use of high-density polyethylene, aramid or carbon fiber in the design.

Another weaver of 3-D fabrics, 3TEX Inc. (Cary, N.C.), manufactures 3-D woven and braided preforms on customized looms built entirely in-house. The company’s line of ballistic materials, trademarked 3WEAVE, is made with reduced crimp (bending at warp/weft crossover points), which can damage fiber and reduce fabric performance. The fabrics are sold in thicknesses ranging from 0.02 inch to 3 inches (0.51 mm to 76.2 mm). Don Wigent, product manager for 3TEX, says the company has been selling preforms at high volume, with thicknesses of 1 inch/25.4 mm or more. The preforms can be stacked to build ultrathick sections of armor, ranging from 6 inches to 12 inches (152.4 mm to 304.8 mm).

Currently, the company’s preforms are used in a variety of heavy armor applications, such as armored doors, floors and panels for military vehicles and naval vessels. 3TEX also produces thinner preforms for body-armor insert panels. Wigent reports the company also has an ongoing program with the U.S. Department of Homeland Security to develop and manufacture a composite panel system for ballistic protection of internal and external walls of government buildings.

3TEX’s customized looms can make hybrid preforms from aramid fiber (Kevlar from DuPont Protection Technologies, Richmond, Va.), glass fiber (E-glass from PPG Industries and S-2 Glass from AGY), high-molecular-weight polyethylene (HMWPE) fiber from DSM Dyneema, and carbon fiber supplied by Hexcel and Toray Carbon Fibers America (Flower Mound, Texas). The resulting preforms have “as many as 20 discrete layers that are stitched together from top to bottom with z-direction fibers,” says Wigent. Given a specific ballistic performance level, cost vs. weight optimization drives hybrid preform design. Moreover, the company’s computer-controlled looms enable designers to quickly alter fabric construction to meet the requirements of different applications. Wigent maintains that the technology can be used to tailor thickness and stiffness in discrete areas of the preform and create armor with property gradients across the width and length of the structure.

T.E.A.M. Inc.’s Tomich thinks applications for 3-D woven hybrid preforms are likely to grow. “From a commercialization point of view, I think what is most interesting is that hybridization, enabled by 3-D weaving, might allow us the ability to substantially reduce cost while maintaining equal performance and weight relative to other designs,” he says. For armor designs that comprise a ceramic-tile facing and a composite backing, Tomich claims there is a clear-cut advantage, in terms of performance and weight, in substituting a hybrid 3-D woven backing in constructions currently built with a 2-D laminate backing.

New materials optimize solutions

The U.S. Army is conducting final tests on its next-generation soldier headgear, known as the Enhanced Combat Helmet (ECH). Expected to be released this year, the helmet comprises a carbon-fiber inner cage overmolded with a preform made from Spectra ultrahigh-molecular-weight polyethylene (UHMWPE), supplied by Honeywell Advanced Fibers and Composites (Colonial Heights, Va.). The design of the ECH reportedly results in 10 percent ballistic protection improvement at a lighter weight compared to the previous-generation helmet it will replace, the Advanced Combat Helmet (ACH), which is made of DuPont Kevlar and phenolic resin (see “Editor's Picks,” under "Learn More" at right).

Improvements in the ECH notwithstanding, designers and suppliers are already seeking ways to build an even better helmet, with some tangible results. Once again, new types of hybrid structures show the greatest potential for achieving the often contradictory objectives of improving ballistic performance and reducing weight and cost.

Researchers at DuPont Protection Technologies have conducted Taguchi-style design-of-experiments testing to evaluate the economic and ballistic benefits of different combinations of fibers, resins, fabric density and processing conditions on helmet design. The investigation covered a broad range of helmet types, variously designed to meet standards used in military and nonmilitary applications.

As a result, DuPont introduced a new design for a multipurpose (military and nonmilitary) helmet at the 2010 Association of the U.S. Army (AUSA) trade show. The helmet comprises a ballistic core (consisting of the company’s new aramid-fiber grade Kevlar XPH 170) sandwiched between inner and outer shells featuring a polyvinyl butyral (PVB) phenolic resin supplied by Lewcott Corp. (Millbury, Mass.). With a commercial prototype in trial with several helmet manufacturers, the helmet is approximately 20 percent lighter than the ACH, according to Jeffery Hanks, senior research associate at DuPont. Hanks says the commercialization of lightweight, lower-cost, hybrid-material helmets hinges on the development of new resins. “When designing helmets consisting of hybrid materials, you often find yourself fighting compatibility issues related to the resin and processing conditions required by the different materials,” Hanks says. He reports that DuPont is conducting research internally and working with suppliers to find and produce resins compatible with a wide range of fibers and fabrics.

Dana Granville, composite materials engineer, U.S. Army Research Laboratory (Adelphi, Md.), says improved use of modeling and simulation tools, such as finite element analysis (FEA), which can mimic microscale resin/fiber interactions right up to the macrolaminate scale, may permit designers to make a shopping list of performance objectives and then build armor and multifunctional structures for specialized U.S. Department of Defense (DoD) applications. “Computational materials science will greatly assist in letting us know how to build composites before we make the costly investments in tooling and process equipment,” says Granville.

Armor Designs Inc. (Phoenix, Ariz.) is using an advanced computational manufacturing technology called Volumetrically Controlled Manufacturing (VCM) to do that right now. Based on an inverse FEA method, VCM is a proprietary technology that combines design and manufacturing processes to optimize advanced composite structures for specific performance requirements. Engineers input a specific ballistic performance level, weight or density limit, dimensions and other parameters, and the VCM software specifies a design that automatically generates material construction of the laminate, processing conditions and CNC tooling paths.

Phil Clement, CEO of Armor Designs, says the company used VCM to manufacture the lightest National Institute of Justice (NIJ) Level 4 body-armor plate on the market. The plate, which is not used in conjunction with a soft-armor vest, comprises a ceramic facing and UHMWPE fabric backing. The company also produces body-armor plates for NIJ Level 3 and 3A protection standards. Clement reports that customers for the plates include European military branches and police agencies in the U.S. and elsewhere in the world.

AGY has recently expanded its composite armor portfolio with two new S-glass fibers, trademarked Featherlight and Quicksilver. The new fibers are being used by manufacturers in ongoing up-armoring projects intended to enhance ballistic protection against improvised explosive devices (IEDs) and explosive formed projectiles (EFPs). The fibers also will help reduce the weight of military vehicles in service in Iraq and Afghanistan. Featherlight glass fibers reportedly provide an increase in protection of 5 to 10 percent over standard AGY S-2 Glass composite armor, thus giving armor designers the potential to build armor that provides the same antiballistic rating at a reduced weight. Quicksilver S-1 glass fibers are intended to be a stronger, stiffer alternative to E-glass fibers in armor applications where weight reduction is deemed less important. Both fibers are compatible with a variety of manufacturing processes, including compression-molded laminating, thermoforming and 3-D weaving.

NP Aerospace Ltd. (Coventry, England) is using AGY’s S-2 Glass in parts of the company’s Advanced Composites Demonstrator vehicle. The shell of the demonstrator pod is designed using the AGY HJ1 Armor System, which is also a significant component in NP Aerospace’s trademarked CAMAC Lightweight Composite Armor system. The CAMAC system has been used as the core ballistic and blast protection system on a full range of vehicles supplied by NP Aerospace.

DSM Dyneema has significantly expanded its production capacity in the past two years at the company’s plant in Greenville, N.C., a direct result of increased demand for Dyneema UHMWPE in antiballistic products purchased by the U.S. military and law enforcement agencies. The company’s unidirectional hard ballistic composite material, HB26, recently saw its first commercial application in helmets used by the Denver Police Dept. (Denver. Colo.). The helmets are manufactured by Protech Armored Products (Pittsfield, Mass.) and are reportedly 15 percent lighter than comparable aramid fiber-reinforced helmets.

Security threats to people, planes, ships, vehicles and buildings are unlikely to diminish in the future. Moreover, more than 10 years of field testing in the Iraq and Afghanistan battle arenas has highlighted an urgent need for armor lightweighting, particularly in the interest of vehicle mobility and fuel efficiency. Although the Iraq conflict has abated, battlefield comparisons of armor designs will continue to drive armor development for years to come. These circumstances should ensure that composite materials will continue to play a critical role in the development of new antiballistic products.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

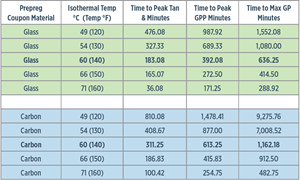

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More