Ashland unveils low-density, high-performance SMC

Ashland's new Arotran 771 sheet molding compound (SMC) offers a specific gravity of 1.2, with good mechanical and physical properties. The company is targeting 1.0 specific gravity, which would put SMC on par with aluminum in automotive applications.

Ashland, to assess the performance of its new 1.2 specific gravity Arotran 771 SMC, fabricated an automotive panel to Ford Motor Co. specifications and then tested it for E-coat tolerance. The material showed no blistering, which is seen as key to winning a place on production cars and trucks.

Michael J. Sumner, group leader – gelcoat, SMC, marine resin, Ashland Performance Materials (Columbus, OH, US), reported at SPE’s Thermoset Topcon (April 19-20) on the development of Arotran 771, the company’s newest sheet molding compound (SMC), designed specifically for use in automotive applications. Prompted by customer demand for a tough, low-density, E-coat-capable, cost-effective SMC, Arotran 771 offers a specific gravity of 1.2, along with some impressive physical and mechanical properties.

Sumner walked attendees through the SMC’s development, with particular emphasis on the evaluation of resin performance. Ashland looked at various combinations of vinyl ester and unsaturated polyester resin (UPR), testing for finished part surface quality, mechanical performance, Tg and E-coat tolerance.

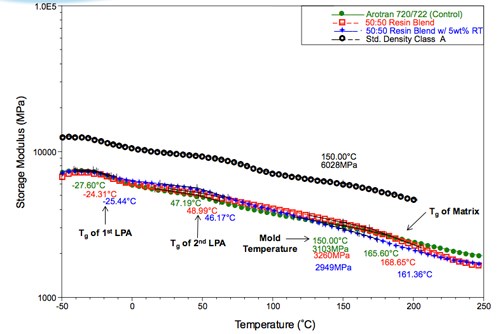

Tg of Ashland's new Arotran 771 SMC (50:50 blend, with 5 wt% resin toughener in legend). The material offers a specific gravity of 1.2, with good strength and toughness, along with the ability to tolerate the E-coat process.

Initial tests of surface quality, as measured by advanced laser surface analyzer (ALSA), showed that a 50:50 blend of vinyl ester and UPR was optimal, with an ALSA value of 64. Ashland added a 5 wt% reactive toughener to the mix and got very good mechanical values: tensile strength 85 MPa, tensile modulus 8,600 MPa, flex strength 182 MPa, flex modulus 8200 MPa and elongation 1.41%. Drop dart impact resistance is 3.1J.

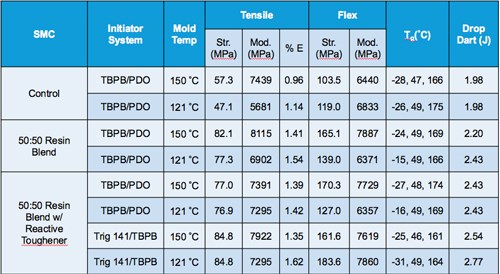

Further testing, Sumner says, revealed that the selection of initiator system and mold temperature can influence part quality. Ashland conducted a series of tests, combining different initiators with mold temperatures of 121°C or 150°C and evaluated surface quality and mechanical properties. The best-performing combination included the reactive toughener and a mold temperature in the 121-150°C range (see table).

Mechanical properties of Arotran 771 SMC (50:50 blend with toughener) compared to

non-toughener and standard SMC at two mold temperatures, with different initiators.

To assess E-coat performance, Sumner says Ashland fabricated several SMC panels to a Ford Motor Co. specification and ran them through the Ford E-coat test protocol, involving exposure to 38°C/100°F and 100% humidity for 10 days, followed by short-term exposure to 200°C/392°F heat. The panels showed absorption of 2.25% with no blistering, the latter of which is required to pass the test.

Arotran 771 represents a substantial increase in SMC performance, comparable to the TCA Ultra Lite brand SMC — also 1.2 specific gravity — introduced in 2015 by Continental Structural Plastics (CSP, Auburn Hills, MI, US). Sumner says Ashland is trialing Arotran 771 with several customers involved in the automotive supply chain.

In the meantime, Ashland is not standing pat. Sumner reports that the company is already working on chemistries to help push SMC specific gravity down to 1.1 and, eventually, 1.0. And those products could come on the market relatively soon. “If we can get to 1.0,” Sumner asserts. “We can effectively compete with aluminum.”

Related Content

Aptera joins forces with C.P.C. Group to accelerate solar EV production

Specialized composite bodies are being produced in Modena, Italy, for Aptera’s BinC vehicle, enabling eventual manufacturing ramp-up of 40 vehicles/day to meet demand targets.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreDieffenbacher acquires Schmidt & Heinzmann composites business

The acquisition, which includes all intangible assets of the business unit, will expand Dieffenbacher’s SMC delivery spectrum, enable potential for portfolio growth and synergies.

Read MoreAOC introduces UV-Resistant Automotive System for SMC parts

AOC’s novel formulation, tested in the lab and in real-world environments, delivers a deep black, molded-in color that resists fading and offers high scratch resistance.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More