Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

NanoXplore Inc. (Montréal, Quebec, Canada) is one of the largest producer of graphene nanomaterials. The company is capable of producing 4,000 tons/year of graphene powder for use in the transportation and industrial sectors, as well as under different applications, including composites. In addition to developing new applications for graphene, and producing standard and custom graphene-enhanced plastic and composite formulations, NanoXplore produces plastic and composite parts for the transportation, renewable energy, energy storage and industrial markets and owns owns several processors/molders/compounders.

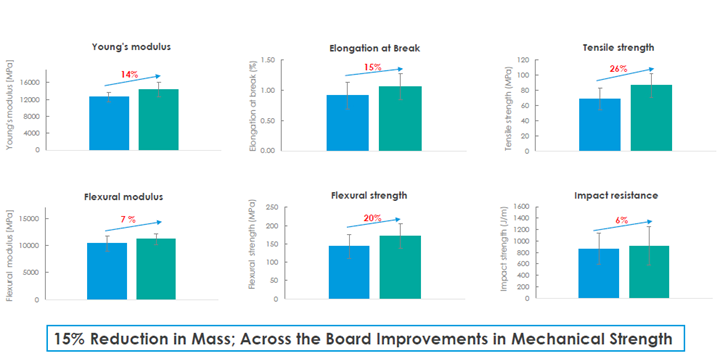

NanoXplore has developed a graphene-enhanced sheet molding compound (SMC) currently sold under the commercial name GrapheneBlack SMC. It provides up to 15% weight reduction versus conventional SMC of the same specific gravity at neutral costs to the OEMs through downgauging, which enables the use of less material per part. Other benefits include increased strength (up to 26% higher tensile, compressive and torsional) and stiffness (better vibrational loading resistance), which provides concurrent opportunities to reduce nominal wall stock.

GrapheneBlack SMC improves moisture resistance of the SMC molded components which lead to less surface blistering after painting and less quality defects as a result. Improvements can be seen in sound damping, UV stability, chemical resistance, and surface finish and paintability. The graphene-enhanced solution reduces stress-crack resistance, and enables process enhancements through better in-mold flow and curing, higher flame retardancy and thermal conductivity.

The GrapheneBlack SMC high-density grade is currently approved and in production for a large transportation OEM exterior panel application. Along with SMC materials, the NanoXplore group of companies also offer SMC molding services to end users and OEMs with multiple large-scale SMC presses available. Applications served are mainly focused on Class A exterior panels and supporting reinforcements but can extend to any SMC application such as battery trays and enclosures, semi-structural components and more.

Related Content

-

AOC introduces UV-Resistant Automotive System for SMC parts

AOC’s novel formulation, tested in the lab and in real-world environments, delivers a deep black, molded-in color that resists fading and offers high scratch resistance.

-

Comprehensive service formulates standard, custom SMCs

CAMX 2024: As an SMC product manufacturer, Molding Products LLC provides SMC formulations and technical support for diverse markets, from R&D to post-production.

-

IDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.