At Composites Europe: A lot of car hoods

As with most composites trades shows and events these days, automotive applications are getting more attention.

The Composites Europe conference and trade show was in Stuttgart, Germany this week (Sept. 17-19). The event has grown nicely the last few years and now boasts more than 600 exhibitors spread across two halls.

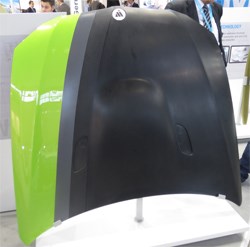

Emphasis here — as at many composites events the last year — was on automotive, and this show in particular featured an unusual number of car hoods, almost all demonstrator parts designed to show the capability of a variety of material types.

Perhaps the highest profile hood was a carbon fiber/epoxy design developed by the Institut für Kunststoffverarbeitung (Aachen, Germany) and machinery maker Breyer Composites (Singen, Germany) in cooperation with Ford Motor Co. The uniqueness of the hood is in the process, which uses gap impregnation technology. In the process, a preform is loaded into a horizontal press (Breyer's). The press is closed, but not fully, and the preform is held 3 mm away from the mold surface by a series of pins located on each side of the mold. Epoxy is injected into the mold cavity at the bottom of the tool until the resin fills about a third of the space in the mold. The pins then retract and the mold closes completely. The resin if forced up into the rest of the cavity and infuses the entire preform. Heat is provided via circulating hot water. Total cycle time is 15 minutes and the hood is ready for paining out of the mold. No word on whether or not Ford will actually put this part into production.

Taking a different tack was a project team whose efforts were driven by automotive engineering and manufacturing company Magna Steyr (Oberwaltersdorf, Austria) and partners Rühl Puromer (Friedrichsdorf Germany, contributing polyurethane resin knowledge), and Hennecke (Sankt Augustin, Germany, the molding equipment supplier). The team developed a demo hood, based on a combination of polyurethane and glass fiber surrounding a paper honeycomb core. Hennecke officials say their goal is not weight savings, but speed of production and meeting the new European pedestrian impact requirements. The honeycomb core and the glass fiber are inserted in the mold and surrounded by a gap of 0.8 to 1 mm. Polyurethane is injected into this gap, pressed and cured. The company says the process produces a finished part with a Class A surface every five minutes.

Moldmaker Frimo (Lotte, Germany) split the difference, showing its own demo hood comprised of carbon fiber surrounding a foam core from 3D Core (Herford, Germany), all infused with foaming polyurethane in a low-pressure process. Paint is provided in the mold, so parts emerge ready-made and feature a highly textured surface. The process, say Frimo officials, has a five-minute cycle time.

All three of these processes, say representatives, are adaptable to other large vehicle structures, like door, body and roof panels.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

.jpg;maxWidth=300;quality=90)