Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

The StrengthBond Offshore project performed more than 250 specimen tests and 115 numerical simulations of laminated/bonded composite patches for the repair of corrosion in steel ships and offshore oil production vessels. Source | Getty Images, JIP StrengthBond Offshore

My 2019 feature article, “Removing barriers to lightweighting ships,” discussed several industry initiatives aimed at expanding the use of composites in large maritime applications. One of the key sources for that article was Stéphane Paboeuf, head of the Composites Materials Section of the classification society Bureau Veritas Marine & Offshore (Nantes, France). Classification societies develop and apply technical standards for the design, construction and maintenance of ships and offshore facilities including offshore oil rigs and floating production storage and offloading vessels (FPSO) that process, store and offload oil and gas from subsea reservoirs.

Steel ships and FPSO vessels are aging and face complex repairs in operation due to corrosion. The most common repair requires downtime in order to use welding torches to cut and weld new steel structure. Source | Bloomberg via InsuranceJournal.com (top) and Getty Images.

Paboeuf says the industry needs a new approach to corrosion repairs of steel structure. “Today, the classic approach is to crop and renew the corrosion with new welded steel girders and plate,” he explains. “But to do that, you have to empty, inert and clean tanks and adjacent structures and stop production to remove the risk of explosion during welding.”

Laminating a composite patch or bonding a plate to restore structural integrity has been proposed as a more cost- and time-efficient solution, says Paboeuf. “This is very interesting because it’s a non-intrusive solution that we can apply directly to the deck of the structure without stopping production.” He explains that a company called Cold Pad (Paris, France) applied this technique to repair a midship deck on an FPSO in 2018. Cold Pad reports that, using its patented ColdShield technology, and in cooperation with Bureau Veritas and TotalEnergies, it completed the world’s first fatigue S-N curve for a composite bonded reinforcement to a steel hull.

Bonded patch repairs (top) completed by Cold Pad offer a “cold” non-intrusive repair method, but lack standard qualification. To address this, composite patch repairs (bottom) were tested in JIP StrengthBond Offshore. Source | Bureau Veritas, JIP StrengthBond Offshore

“So, we do have a few solutions like this approved/certified for ships and offshore structure applications,” says Paboeuf, “but there is no real standard, either for design or qualification.” He adds that while outside of marine applications, pipes and columns are routinely repaired by wrapping with carbon fiber and glass fiber-reinforced polymer (CFRP, GFRP), “there is no standardized repair for wide, flat plates that are primary structure for these maritime applications. And that’s why we decided to launch the joint industry project JIP StrengthBond Offshore in 2019.”

StrengthBond Offshore project

As explained on its project web page, Bureau Veritas is working on several research projects to address aging and durability, including Qualify, Real Tide, RAMSSES and FIBRESHIP. For StrengthBond Offshore, Bureau Veritas worked with a consortium of industry partners with the main objective to qualify bonded composite patch repair.

“To do this, we needed to develop a robust methodology for the strength analysis of such repairs, which requires numerical tools to assess and validate designs,” says Paboeuf. “We also had to define the necessary tests and manufacturing protocols.” These objectives were indeed achieved during the 4-year project. “We performed more than 250 specimen tests and 115 numerical simulations and delivered 30 technical reports. We published 14 scientific papers during the project and presented these at different conferences across Europe. A Ph.D. thesis was also published during the project on the strength of the bonded repair.”

StrengthBond Offshore project testing pyramid and work completed. Source | JIP StrengthBond Offshore

“The main result is a project guideline for the qualification and certification of a composite patch repair for steel structures,” he continues. “And this is illustrated with applications that we have developed and used during the StrengthBond Offshore project. The largest challenge was to identify the parameters for numerical simulation — which ones are necessary and how to determine these. That’s why we tested so many specimens.” That testing also led to the development of a new type of coupon: the equivalent interface specimen. We’ll discuss that in more detail below, and also the project’s next phase, as Paboeuf explains: “Now, we have to define which kind of aging tests are required to predict the long-term behavior of these composite patch repairs.”

Large area repairs, carbon fiber, repair processes

Although composite repairs have been used for decades on aircraft, marine, and construction and infrastructure applications, use in large offshore units has been limited. Here, the composite is not bonded to composite substrates, but to steel. Also, a key issue addressed in StrengthBond Offshore is that these composite patch repairs are also quite large, as Paboeuf details: “Bonded composite repairs for aircraft are typically a local repair, say several centimeters, compared to the large repairs we’ve considered. These can be 40 square meters and affect the vessel’s hull or deck strength. We have seen some approved/certified composite patch repairs to steel vessels, but they are more in the size of typical aircraft repairs — so just sustaining local loads and not global loads. But with StrengthBond Offshore, we looked at global loads, which requires a much more complex analysis for simulation and predicting failure.”

To achieve sufficient stiffness for the large area repairs to primary structure, the patch used in StrengthBond Offshore comprised mainly carbon fiber plies. “Excessive thickness would be required if we used glass fiber,” says Paboeuf, “but we did use some layers of glass fiber between the carbon fiber and the steel to prevent galvanic corrosion.”

The repairs were designed using epoxy resin in the patch without an adhesive, and the patch repair was tested using two different manufacturing processes: vacuum-assisted resin infusion and vacuum bagged hand layup. The epoxy resin was also post-cured at 80°C for a total cycle of 16 hours. “When we compared the two different manufacturing processes, we saw more or less the same strength. There was no impact from the manufacturing process,” he explains. “And the methodology we developed is more generic, so that the process can use multiple kinds of resins and fabrics. It also includes which kind of tests have to be performed to qualify these materials.”

Patch design, long and short scarf repairs

Layup of the bonded repair patch where blue and gray plies are carbon fiber, green plies are glass for galvanic isolation and the steel substrate is orange. The long and short scarf angles tested are shown at top right.

The goal of the composite repair is to regain the lost stiffness of the steel structure caused by corrosion. The loss of steel thickness to be recovered was evaluated to be roughly 7 millimeters for a 20-millimeter-thick sheet. Under these conditions, the design of the bonded patch led to a proposed composite layup of unidirectional plies shown in the diagram above. The gray/blue/black layers correspond to carbon fiber plies, while green plies of glass fiber provide isolation to prevent galvanic corrosion with the orange layer representing the steel substrate.

Long and short scarfs at the edges of the patch (at top right of the figure) were proposed to study the influence of the scarf angle and resulting stress concentrations on the strength of the bonded repair. “The long scarf showed a 38% higher repair patch strength versus the short scarf,” says Paboeuf.

Equivalent interface test specimen

Bonding FRP patches imposes significant constraints on the design. “The patch end is placed in a fully stressed zone subject to unit tensile and bending,” explains Paboeuf, “causing high stresses on the edges of the reinforcement.”

Thus, designers and engineers face several difficulties related to the nature of hybrid steel to composite joints, including the difference between the composite and steel material properties and singularity at the edge of the patch. Paboeuf explains that the cohesive law determines the failure of such bonded patch repairs. Thus, it was necessary to characterize the multiple interfaces within the bonded composite patch, including: the GFRP to steel interface, the GFRP ply to ply interface, the CFRP to GFRP interface and the CFRP ply to ply interface for both tension and bending loads.

The different toughness properties of each interface would typically be assessed using standardized tests such as End Notched Flexure (ASTM D7905) or Double Cantilever Beam (ASTM D5528) tests, and simple theories based on linear elastic fracture mechanics. However, the StrengthBond Offshore team wanted to limit the number of physical coupon tests. Thus, a new kind of sample which includes all the different interfaces was designed based on the existing ASTM standards just mentioned, as well as Mixed Mode Bending test (ASTM D6671).

“We named this the equivalent interface specimen and used it for all the tests,” says Paboeuf. “And all of these tests were also simulated with finite element analysis [FEA]. Using the equivalent interface specimen allowed us to determine the toughness of the edges of the composite patch repair and we were able to determine the parameters for the cohesive law that we used in the FEA. We then compared the simulation results using this cohesive law with results from the physical testing we performed on large-size specimens, and saw a discrepancy of 3% in tension tests, which is a very good result, especially for simulation of an adhesive joint. For the bending tests, the discrepancy was higher, which demands further work.”

More details on this test method will be presented in a future Predicting Failure column: “Using a new equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structure.”

StrengthBond Offshore results

As stated above, by the end of the project more than 250 specimen tests and 115 numerical simulations had been completed. This included fatigue testing on large-size specimens, comprising 50,000 to 5 million cycles, depending on the load applied.

The graph at right shows the results for different amplitudes of force, where orange squares correspond to the test results (at break) and blue arrows show the tests which have not broken. From these measurements, the fatigue curve was plotted as the straight black line and compared to that of a reference FPSO unit in green at lower left. This shows that the service life of the composite patch is much greater than that of the reference ship histogram.

The vertical blue line in the graph corresponds to a target lifetime of 20 years which equates to 63 million cycles. Thus, these fatigue test results predict that the bonded patch lifetime, under real loading conditions and without external damage, will greatly exceed the lifetime of the ship. The high safety margin (difference between the theoretical and experimental lifespan) provides a very good level of confidence in the behavior of the bonded patch in real conditions.

“We also applied this methodology and technology on a full-scale structure,” says Paboeuf. “We didn’t install a patch onboard a vessel, but we demonstrated a real case application and tested it in the lab. We did initially plan to complete an onboard installation during the project, but unfortunately we didn’t have the budget for this. Although Bureau Veritas completed a previous bonded repair installation project with Cold Pad, it was a bonded metal patch and not a composite patch. Now, we’d like to install a large composite laminated patch on an offshore unit.”

Significantly, the StrengthBond Offshore project enabled issuing a methodology for the bonded composite repairs, which includes the best approach for repair design and materials characterization, as well as procedures for surface preparation. “These are mainly grit blasting followed by solvent wipe, which is standard in bonded composite repairs,” notes Paboeuf. “We tested different surface preparation methods and selected the best one. In the published methodology, we also discuss process control during patch application and guidelines for monitoring this, including vacuum bagging and cure temperature details.” He notes the latter depends on the resin used.

“Thanks to what we developed during this project, we are now able to predict with good confidence the failure and load of these large-scale bonded composite repairs,” says Paboeuf. “Also, thanks to the new equivalent interface specimen that we developed, we are able to use the cohesive law for numerical simulations, which enables a good prediction of failure. We have achieved a robust methodology for design assessment of bonded reinforcements to steel structure, and that’s important for classification societies to be able to justify the strength of the repair and validate the failure load and safety factor.”

Next phase: DuraBond Offshore project

Planned work packages to be completed during the DuraBond Offshore project. Source | JIP Durabond Offshore

Paboeuf says the consortium would now like to investigate environmental effects on the strength of the laminated composite patch. “In maritime applications, we don’t use chicken rivets in bonded primary structure repair. That’s why we have to confirm the long-term behavior, especially because we know we will have high humidity, high temperature and sometimes pollution from chemical agents and so on. So, we have to confirm the resistance of the composite patch repair against this aggression and the combined effect with fatigue from cyclic loads.”

Thus, the new JIP DuraBond is a 3-year program launched in November 2024 with mostly the same partners. “InfraCore will not be part of the new project but we are now joined by FUZE Solutions [Perth, Australia], a company that is performing composite-wrapped pipe repairs,” says Paboeuf. “And we are always open if there are new companies who want to participate in the project.

“In DuraBond, we will put the specimens in water and hydrocarbons, expose them to high and low temperatures and then test them in tension after aging,” he continues. “These tests will include static loading and also in fatigue, so that we can evaluate the influence of the environment on the strength of the patch in order to tune the safety factor and confirm the long-term performance. We will also be working again with Gustave Eiffel University [Bouguenais, France] to complete this testing, as well as with Nantes University [Nantes, France] and the University Federal of Rio de Janeiro in Brazil.” He notes the latter already has experience on the aging of composites in oil. “But just as in StrengthBond Offshore, we will complete a comprehensive test program, and again publish guidelines to enable the approval/certification and wider use of these repairs.”

Read more about Bureau Veritas’ work with composite materials and adhesives, about the JIP StrengthBond Offshore and about the DuraBond Offshore project.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

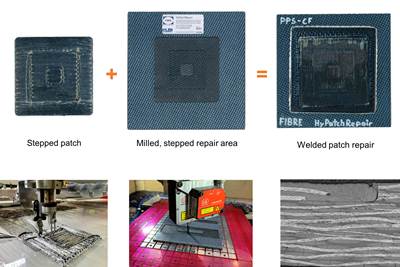

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreAerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More