Blade repair: Closing the maintenance gap

Citing difficult work conditions, lack of OEM guidance and underdeveloped inspection technologies, those who service wind turbine blades seek remedial solutions.

Composite wind turbine blades are designed to last for 20 years in the field. But those who service them say that without proper maintenance and repair, their actual service life will fall short, and during that shorter life, overall turbine efficiency will diminish. In fact, every defect on the surface of a wind blade disrupts its aerodynamic efficiency and, as a result, reduces the turbine’s power production. Blade repair and maintenance, then, is no small matter.

Its importance, however, is not uniformly recognized. “The European wind market is more mature than the U.S. market and recognizes that proper maintenance begins with regular inspection,” claims Josh Crayton, blade services manager at Rope Partner Inc. (Santa Cruz, Calif.). “Insurers in Europe require biennial, up-close, visual inspection of every blade in every wind farm.” In the U.S., the need for regular blade inspection and maintenance has been largely ignored, but Crayton believes wind farm operators in the U.S. are beginning to see the value of regular blade maintenance.

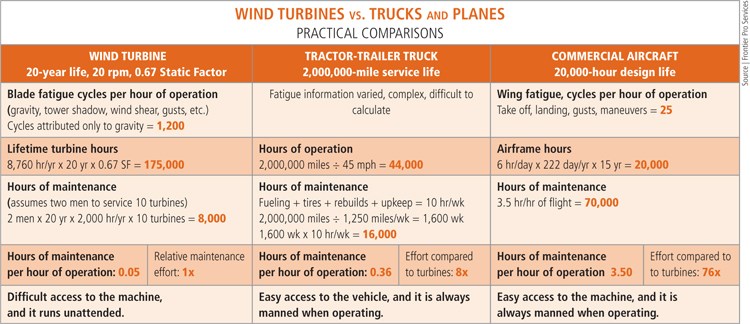

Mark Dawson, PE, Frontier Pro Services (Banning, Calif.), sees the need to close a significant maintenance gap. Rotor blades are expected to have four times the design life of a tractor-trailer truck, yet they currently merit only one-eighth of the maintenance hours, he estimates. Compared to commercial aircraft, which have a 20,000-hour design life, today’s composite wind blades suffer 48 times the hourly fatigue and are expected to log 8.75 times more service hours, but they receive only 1/76th the number of maintenance hours (see comparison chart at right). David Cripps, global account manager, Gurit UK (Isle of Wight, U.K.), suggests that one reason for the disparity in maintenance is that the ever-increasing volume of blades in the fast-growing wind energy industry is stretching the ability of the repair community to supply services to match demand.

Pay now or pay later

Certainly, no one in the blade repair community doubts the necessity. “Turbines are much like an automobile,” says Crayton, noting that “if you don’t rotate and balance the wheels, they will begin to send vibrations throughout the entire vehicle and affect the car’s mechanics,” he explains. “Wind farm operators are now realizing that if the rotor is out of balance, it will affect the entire turbine.” The effect can be something minimal yet annoying, such as increased noise, or it can be more dire, including the possibility of catastrophic failure.

“A good preventive maintenance program identifies potential problems and fixes them before they affect the operational efficiency,” says Gerry Bender, business development manager, Wind Energy Services (WES, Gainesville, Texas), a wholly owned entity of the Molded Fiber Glass Companies (Ashtabula, Ohio). Prevention, he says, “is gaining a lot of traction as an essential best practice.”

Prevention, however, isn’t everything. Impact damage and environmental wear inevitably make repairs necessary, says Gurit’s Cripps.

“It’s surprising how much damage we see that is caused during transportation and construction,” says Crayton. “Wind blades are not meant to undergo these dynamic forces.” Even when specially designed cradles are used for transport, trailing and leading-edge damage can occur, he explains. The trailing edge might experience some minor crushing of the laminate, and damage to the flange and sandwich structure of the leading edge can be far more significant and, oftentimes, cannot be seen on the surface,” he adds. “In addition, we often witness construction timelines that force the installation of rotors without sufficient time for inspection and proper repair on the ground.” Other minor damage, such as surface scraping or gouging, can be caused by forklifts, lifting straps and careless handling.

“Transportation is going to be a constant challenge for wind blades,” cautions Crayton. “The technology is scaling so much that manufacturers are constantly forced to reassess how best to transport these larger composite structures. Already, blades are near their maximum size for road transportation, and given that these installations are in rural areas with geographical limitations, this is an issue that must be addressed,” he adds.

During operation, as blades rotate, the blade tips can reach speeds of 180 mph/290 kmh. At that speed, rain- and wind-borne contaminants and sand can heavily erode leading and trailing edges. “Turbines are erected in many different environments, from bitterly cold to scorching hot and everywhere in between,” says Cripps. “Thermal cycling, dust and debris erosion and fatigue are common reasons to require blade maintenance,” he says.

In the harshest environments, leading-edge erosion is evident as soon as two years after installation. As the edges erode, the airfoil is affected and, unless it is remediated by maintenance and repair crews, overall production of the turbine is reduced. (Blade designers are seeking ways to better protect edges via new materials. See the "Leading-edge erosion: Materilas solutions" sidebar under "Editor's Picks," at right, or finish reading this article and find the sidebar at the bottom of this page.)

Lightning also is a common source of damage, despite the best lightning protection technology. Blades are designed to reroute lightning strikes to the ground. Typically, a small copper plate near the blade tip acts as a conductor and feeds the lightning through heavy wires to the base of the blade and down to the ground. Crayton acknowledges that lightning protection technology is improving. “Lightning protection system designs are scaling to meet the forces of nature, driven by increased data accumulation from the field,” he notes, but he maintains that minor surface scarring and, sometimes, greater structural damage can and does occur.

“Scorch marks on the surface of the blade shells leave a pitted and blackened surface,” explains Cripps. “Commonly, this damage appears as puncture holes in the blade shell, which leaves the core exposed to water penetration.”

Even when built-in lightning protection successfully protects the blade shell laminate, any moisture in the blade at the time of a lightning strike can be the source of secondary damage. Lightning can produce very brief but extraordinarily high temperature spikes — as high as 50,000°F (27,760°C). During the spike, water turns to steam. Damage from the subsequent pressure expansion can range from delamination and cracking to debonding and spar separation.

Issues with inspection

The key issue in blade maintenance is inspection. The most common form of inspection is visual, from ground level, using a high-magnification scope, says WES’s Bender. “Using a scope from the ground, we can identify visual signs of damage, including stress cracks,” he says. To address damage, such as delamination, that lies unseen beneath the blade surface, however, wind farm operations and maintenance (O&M) companies are turning to nondestructive inspection (NDI).

Unfortunately, wind blades present a number of challenges for inspection technology, reports testing and consulting firm Exova (Mississauga, Ontario, Canada). Foremost is laminate thickness. Blade skins that range from 20 mm to 60 mm (0.78 inch to 2.36 inches) make it difficult for NDI technologies to “see” critical bond lines, says the company. But obstacles also include the blade’s varying curve geometries, cost and time constraints and the need for NDI equipment portability. To date, two forms of NDI are beginning to make inroads into blade diagnostics (for more information and background education about NDI, see “Assessing cnventional and advanced NDI for composite aircraft” and Nondestructive testing broadens its scope," under "Editor's Picks").

Ultrasound technology is suitable for detecting flaws within the bonding areas beneath several centimeters of composite laminate. Ultrasonic local resonance spectroscopy could replace manual tap tests to identify damage near the surface of the blade. Many companies are working to develop suitable solutions. Exova is adapting ultrasonic phased-array sensors for use on curved geometries and to identify out-of-plane waviness (wrinkles) deep within the laminate structures. The process involves pulsing each small element on a phased-array probe one by one at various times. When done in a sequence and in a row, a constructive interference pattern is generated, which results in a beam that can be steered electronically.

Shearography — currently used in aerospace and marine industries — is also an option for wind blade inspection in the field, according to Dantec Dynamics (Skovlunde, Denmark), which manufactures laser optical measurement systems and sensors, including the Q-810 portable laser shearography system. Dantec is working with Rope Partner to develop laser shearography for up-tower use. Reportedly, the technology can identify subsurface defects, such as wrinkles, delaminations, disbonds, kissing bonds, porosity, crushed core and core displacements in sandwich laminates comprising a range of materials, including carbon and glass fiber, honeycomb and foam. The results show strain distributions and hot spots.

The handheld Q-810 system consists of a vacuum and/or thermal excitation hood with an adaptive seal that allows it to be passed over flat and curved surfaces. It incorporates a touch-screen display mounted on the hood for remote control of the measurement. The results are displayed in real time, allowing the operator to detect any variation or anomaly in the field of view. The images are automatically stored for later review and reporting.

“There is no surface preparation required, and 150 ft2 [14m2] can be scanned per hour,” reports Rope Partner’s Chris Bley, company founder and R&D director.

Field experience counts

Damage repairs are fairly straightforward. Wet layup is the standard technique, and both polyester and epoxy wet laminating materials are used for surface erosion and structural repairs.

“When teams develop a repair scheme, it’s critical that they understand the nature of composites, resins, fibers and orientation,” stresses Abaris Training Resources Inc.’s (Reno, Nev.) chief instructor, Dave Castellar. This is even more critical when teams are faced with a lack of information about proprietary material specifications from blade OEMs after warranties expire.

“Postwarranty, wind differs from the aerospace industry, where you would never undertake a structural repair without specified work instructions and materials,” says Crayton. And although materials suppliers can be a valuable resource, what blade repair technicians in the field need most is training and experience. “Few companies,” he says, “have all the pieces in place to assure a high standard of quality.”

“Having years of experience behind us is our value proposition,” adds Peter Wells, business leader for the Blade Services Team of UpWind Blade Solutions (Medford, Ore.), which recently acquired Medford-based Knight & Carver Wind Group’s Blade Services business. “We now have a large base of proprietary work instructions for various types of blade repairs, which are based on years of experience in the field,” says Wells. “Understanding the nature of different types of damage and being able to diagnose the correct repair that is repeatable, based on work instructions, and executable, due to technician training and expertise, is essential,” he adds.

Faster cure in lower temperatures

Low temperatures limit the repair window for blades. Fast hardeners can be used to accelerate cure time at lower temperatures, but Gurit’s Cripps warns that aggressive use of hardeners exposes repair firms to the risk that resin could gel before heavy repair fabrics are fully wet out. Heat blankets and infrared (IR) heaters can be used to ensure cure in cool weather. Although hardeners and/or heat accelerate cure, blades repaired with conventional catalyzed resins must nonetheless remain stationary for 24 hours to adhere to Germanischer Lloyd (GL) repair-quality certification requirements.

Cripps contends that two-component resins require offline mixing that must be done in temperatures greater than 15°C/59°F to avoid handling issues. Moreover, excess mixed resin is wasted.

These limitations have raised interest among O&Ms in the use of UV-curable resins, which cure within minutes and whose cure mechanism is not heat dependent. “UV as a curing method for resin, paints and ink is not a new concept,” says Cripps, whose company offers the RENUVO family of UV blade repair systems. RENUVO systems are available in two grades. The summer grade has a working temperature range from 15°C to 30°C (59°F to 86°F). Gurit’s winter grade, however, ranges from 5°C to 18°C (41°F to 64°F) — 10°C less than conventional resin working temperature. “These different grades are designed only to ensure that the material has the optimum handling characteristics at the given application temperature,” says Cripps, who points out that “the curing of the materials is unaffected by the temperature, occurring entirely with the correct dose of UV light.”

“What is unique about the RENUVO development,” Cripps claims, “is the industrialization of the curing equipment in combination with the development of specific UV resin technology that meets both the handling needs of the repair technicians and the structural needs of the blade designers and certification bodies, such as GL.”

The approach is fairly straightforward, beginning as any repair would with an inspection and assessment of the damage and then surface preparation. For small repairs that require no fiber reinforcement, Gurit offers RENUVO MPS (multipurpose system) resin, which is applied directly to the damaged area via a standard cartridge gun. The MPS resin, which is suitable for use on polyester or epoxy substrates, is a monocomponent system that requires no separate hardener. “It has the consistency of grease and, therefore, can be spread easily to repair small surface scratches, and yet it is thixotropic enough to fill small holes as well,” explains Cripps. To extend working time, the RENUVO material should be applied out of direct sunlight. For cosmetic repairs, curing is completed using a handheld, battery-operated spot lamp. In small patch repairs as thick as 3 mm/0.12 inch, the MPS resin reportedly can be cured by the spot lamp in 90 seconds.

For a structural repair, the MPS resin is combined with RENUVO PP — a UV-curable biaxial or unidirectional prepreg. “Since the RENUVO materials have an almost indefinite working time when not exposed to the correct UV light, complex, multilayered repair patches can be assembled offline, if required,” says Cripps. When building a repair patch for structural damage, such as that seen in leading-edge erosion, a clear plastic UV blocker is used as the base of the repair. The correct offset of the different prepreg layers is achieved using a template placed under the clear plastic. Folding the excess plastic over the prepreg seals the patch into a clear envelope. It is then placed into the RENUVO heated vacuum consolidator, which fuses the prepreg layers together without curing them.

After 15 minutes, the sealed envelope is removed. The clear UV blocker film is removed from the backside of the patch and trimmed to provide a 10 mm to 15 mm (0.4 inch to 0.6 inch) excess around the edge of the patch. A bead of MPS resin is applied to the prepreg and spread to an even thickness of approximately 1 mm/0.39 inch. This MPS layer then acts as a tie between the prepreg patch and the blade. The finished repair patch is then rolled up and placed into a specially designed storage device, which is sealed to prevent premature exposure to UV light.

The patch then can be transported to the blade and placed over the exposed damage on the substrate. After air is removed (typically with a small roller) the UV protective film is removed from the upside of the patch and an extra coating of MPS resin can be applied if a smoother surface finish is required. Curing — typically 180 seconds for structural repairs — is achieved using RENUVO lamp technology on a specialized indexing system.

Northeim, Germany-based repair and maintenance provider BS Rotor Technic GmbH was an early adopter of the RENUVO system. According to the company’s managing director, Jeremy Sheppard, the RENUVO system allows BS Rotor to eliminate the 24-hour hold time required for wet layup blade repairs.

“Irrespective of site, turbine design, or wind conditions, the cost of energy from any installation will be reduced by ensuring maximum availability and uptime,” says Cripps. “By significantly reducing the time of repair and eliminating the need for a 24-hour delay before starting up, revenue can be increased and therefore the cost of energy is reduced.”

Optimizing service life

If wind energy is to realize its promise, wind turbines must be cost-effective, and generated energy must be competitive with energy from coal and natural gas. That won’t be possible if rotor blade service life is cut short. Repair and maintenance strategies must keep turbines operating optimally and minimize downtime. To meet this mandate, O&Ms must develop quality laminate repair methods characterized by quick cure and they also must adopt preventive-maintenance schemes that make use of NDI.

Many O&Ms are partnering to develop proprietary advances in repair techniques, although details are scarce, given the competitive nature of the industry. UpWind is partnering with NDI developers and materials suppliers to develop faster and more accurate inspection technology, resins and accelerators that can be used in colder weather, and innovations in access technology, says Wells.

Continued training, both internal and external, will be critical as wind blades become larger and more complicated. “As new and improved manufacturing processes multiply the material types and ways that blades are built, constant training will be necessary to keep repair technicians up to date,” says Bender. “Customers want repair quality and documentation equal to that of a manufacturing environment, and as blades in the field age, larger and more structural field repairs will be required.”

“As the industry matures, expectations and capabilities are getting higher,” agrees Wells, pointing out, “There has definitely been a shift in the expectation of customers toward a high level of service and a maturity in the service provider’s ability to deliver that level of quality.”

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

Nondestructive Testing Broadens Its Scope

Automation and integration of advanced NDT methods lead to faster, more accurate flaw and damage detection.

Read MoreLeading-edge erosion: Materials solutions

Depending on operating conditions, erosion of rotor blade leading edges can affect wind turbine energy generation efficiency as soon as two years after installation.

Read MoreAssessing conventional and advanced NDI for composite aircraft

AANC experiments test how well damage can be detected in composite parts.

Read More