The carbon fiber composite roof of the Maserati MC20 is achieved using HP Composites’ AirPower technology, a derivative of bladder-assisted compression molding (BACM). Source |Maserati

In the realm of high-performance automotive manufacturing, carbon fiber-reinforced plastic (CFRP) components have become increasingly crucial for achieving optimal strength-to-weight ratios and complying with stringent efficiency requirements. However, traditional CFRP production methods, such as autoclave curing, often struggle to meet the demands of automotive production rates, consistency and cost-effectiveness. HP Composites (Ascoli Piceno, Italy) has developed its proprietary AirPower technology to address these challenges head-on.

By integrating a derivative of bladder-assisted compression molding (BACM) principles with tailorable material science and process control, AirPower has successfully enabled the production of the Maserati (Modena, Italy) MC20 supercar’s complex CFRP roof at a rate of 1,500 units per year, demonstrating its capability to deliver complex, high-quality composite components at niche, automotive-scale production rates.

Enhancing BACM for automotive applications

AirPower technology builds upon the proven advantages of BACM, which has demonstrated its ability to produce aerospace-grade composite structures with fiber volume contents up to 67% and voids as low as 0.2%. The core of the BACM process lies in its use of an inflatable bladder system within a press mold, enabling the application of tailored pressure control throughout the composite laminate and the entire production process.

The Maserati MC20 features a body structure that highlights a composite central tub and roof structure, which are connected to two aluminum subframes at the front and rear. Source | Maserati

Traditional BACM machinery consists of a metallic press mold with upper and lower sections and an inflatable bladder on the top section that acts as the counter mold for the lower section. HP's AirPower technology enhances this design by introducing a split lower mold design and a custom flexible counter mold that combines the functions of a bladder and a vacuum bag. The split lower mold consists of upper and lower sections, with the lower half being a metallic structure serving as the heated surface, and the upper half being a detachable, thin CFRP shell. This innovative design allows for prepreg ply placement on the upper section without initiating curing while maintaining the lower part at the curing temperature. The shell’s CFRP construction ensures proper thermal and residual stress management due to its coefficient of thermal expansion matching the manufactured parts. The flexible counter mold, mounted to the thin CFRP shell, seals to the outer edge of the lower mold when the mold is closed, enabling the provision of air pressure on the top and vacuum on the bottom of the flexible counter mold during manufacturing.

Vincenzo Castorani, R&D project manager at HP Composites, explains: “The lower part of the bottom mold is kept at the part’s curing temperature while the upper CFRP section acts as a thin thermal separator from the heat source, allowing us to laminate the piece without starting the curing process until we are ready. By maintaining the mold at a constant temperature of 140°C, AirPower eliminates the need for repeated heating and cooling cycles, resulting in up to 50% energy savings compared to traditional autoclave methods.”

Custom inflatable bladder

HP’s flexible counter mold is the key component to its AirPower composite manufacturing tool, as it is designed to apply uniform pressure to the composite laminate, even in areas with complex geometries or undercuts. HP Composites custom designs and manufactures its flexible counter molds for clients, controlling the thickness, hardness and material composition. A highly tailored synthetic rubber is used, made through custom polymerization of monomers to produce the desired characteristics.

This sequence showcases the AirPower process with custom flexible counter mold for manufacturing a specific part. Source | HP Composites

Michelangelo Mastroberti, sales manager at HP Composites, emphasizes the importance of flexible counter mold design. “The thickness of this synthetic rubber is tailored exactly for that flexible counter mold’s role in the pressure application and curing,” he states. “The chemistry of the rubber is homogenous throughout, and its design features [thickness and rubber type], geometry and sealing surfaces are adapted to the part it is producing, ensuring the required durability and consistency throughout the production run.”

The flexible counter mold manufacturing process begins with the preparation of a solid female mold that matches the desired geometry of the bladder. The mold is designed to accommodate the specific requirements of the composite part being manufactured, including any complex shapes, undercuts or integrated inserts. Next, a measured quantity of the custom synthetic rubber material is then applied into the mold.

The custom counter mold for the construction of CFRP components using AirPower technology. Source | HP Composites

The female mold, in combination with the synthetic rubber, undergoes autoclave curing using a specific curing cycle. The sealing portion of the flexible counter mold is crucial for maintaining pressure and vacuum, so it requires special attention.

Once the curing process is complete, the flexible counter mold is de-molded and carefully inspected for defects or irregularities, and any excess material is trimmed away. It then undergoes rigorous quality control checks to ensure its dimensional accuracy, surface finish and mechanical properties, as well as pressure testing to validate performance under simulated manufacturing conditions.

The flexible counter mold manufacturing process, while intricate, is designed to be tailorable and repeatable, enabling the production of duplications to support the manufacturing run of composite parts at automotive-scale production rates. HP Composites has developed specialized expertise in flexible counter mold manufacturing, with a dedicated department focused on the design, production and maintenance of these critical components.

Thermal management and energy efficiency

Thermal management is a critical aspect of AirPower technology. The AirPower machinery is heated using electric resistance, with heated cores passing through the upper and lower metallic press structures. An in-house designed power supply system ensures uniform temperature distribution across the mold surfaces. “Recent manufacturing runs demonstrated a 50% reduction in energy consumption compared to conventional inflatable bladder molding processes,” explains HP’s team. “This increased energy efficiency reduces production costs and contributes to a lower environmental impact.

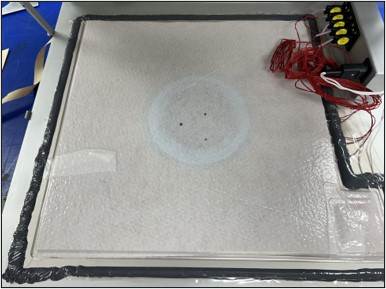

The AirPower machine used for producing the roof structure of the Maserati MC20. Source | HP Composites

“While the AirPower technology requires metallic molds and synthetic rubber countermolds, which initially contribute to higher environmental impacts, these are offset by the extended service life of the tooling compared to autoclave molds,” HP’s team continues. “Additionally, autoclave processing relies on consumable vacuum bags, which must be frequently replaced, leading to additional waste and resource consumption. As the composites industry continues to prioritize sustainability and environmental responsibility, technologies like AirPower will play a significant role in reducing the ecological impact of manufacturing processes while maintaining the high-performance standards required by demanding applications.”

Vacuum line connections in the lower mold section of the Maserati MC20 roof mold enable the application of air pressure on the top and vacuum on the bottom of the flexible counter mold during manufacturing. Source | HP Composites

Maserati MC20 roof material development, structural design

HP Composites partnered with Maserati to manufacture the roof of the company’s top-of-the-line sports car, the MC20, using its AirPower technology. For this application, HP Composites developed a bespoke CFRP prepreg, featuring a weave architecture engineered to optimize both structural performance and manufacturing efficiency. The result is a high-grammage woven CFRP fabric that allows for fewer plies to be used, accelerating the lamination process, with engineered drapability facilitating the production of the roof’s complex geometries.

The stages of prepreg layup for the Maserati MC20 roof structure. In the far left image, the upper layer of the roof structure is laid down. The central image illustrates the bonding phase process with aluminum inserts positioned within the structure. The far right image reveals the interior skeleton layer of the structure. Source | HP Composites

Developing the bespoke CFRP prepreg material involved extensive collaboration between HP Composites and Maserati. The material was characterized through a series of tests to establish its performance characteristics and create material cards. This data enabled the design of the ply book, taking into account the manufacturing process and the need to reinforce critical areas such as the A-pillar and B-pillar.

Gianluca Monsurrò, design lead at Maserati, outlines the design philosophy: “The primary goal was to maximize the integration of the roof with the car’s main body, allowing us to minimize the use of materials while meeting performance requirements and creating the lightest possible roof structure.” The MC20 roof incorporates a series of aluminum inserts, which play a crucial role in its structural integrity and integration with the vehicle. HP Composites also developed a bespoke lamination process to establish a suitably strong connection between the composite and metallic inserts. This process includes surface treatments to prevent galvanic corrosion and ensure strong adhesion for optimal performance.

Manufacturing process optimization

HP Composites designed a bespoke production process for the MC20 roof to ensure effective consolidation and minimal voids. During part consolidation, air pressure above the custom flexible counter mold applies up to 8 bar of pressure onto the top while a vacuum is drawn underneath. The roof construction process involves multiple multilayered CFRP structures bonded together, which must be perfectly matched during the manufacturing process. The firewall is also bonded to the roof structure in the same process.

This image sequence illustrates postprocessing of a specific part. Cooling is managed within the mold by separating the lower mold (far left) into upper and lower section, which prevents a direct thermal pathway between the part being molded and the hot lower section. The part is then removed from the press and further cooling is optimized in a cooling station (center). Once cooling is complete, the CFRP part is demolded from the thermal separator (right). Source | HP Composites

Thermal management during the demolding process was a critical consideration to ensure the geometric stability of the finished product. HP Composites engineered the AirPower equipment to control the cooling rate precisely, preventing any thermal stresses that could lead to part distortion or damage. The cooling rate was carefully balanced to maintain an industrialized process while avoiding damage to the part. From laying up the prepreg to a fully consolidated part takes just 2 hours. Post-cure operations — including trimming, drilling and surface finishing — are carefully executed to maintain the integrity of the composite structure and its interface with the metallic inserts.

Process control, quality assurance

HP Composites employs nondestructive testing methods, such as thermography analysis and ultrasound, as robust quality control measures. The Maserati MC20 roof was subjected to rigorous testing to validate its structural performance and contribution to the vehicle’s overall torsional rigidity and crash safety. The testing regime included cyclic loading to simulate impacts from the road to the main structures of the A-pillar and B-pillar, as well as vibrational tests to understand the bonding between the metallic and composite structures. Castorani notes: “We found that the level of compactness of the laminate and performance was exactly the same as from a far longer and more energy-intensive autoclave manufacturing process.”

The final roof structure, weighing just 26 kilograms, contributes significantly to the MC20’s lightweight design, with the entire vehicle weighing only 1,200 kilograms. The roof’s structural integrity performance under crash situations met all the required targets, demonstrating the effectiveness of the AirPower technology in producing high-performance composite components.

Scalability and industry impact

At maximum production capacity, HP Composites can manufacture eight MC20 roofs per day in a two-shift operation. Mastroberti highlights the technology's scalability advantage. “To produce the 1,500 production run sets per year for Maserati, we needed only eight flexible counter molds in total. To do the same with autoclave technology, you’d need 30-plus molds and a considerable number of autoclaves.”

The success of the MC20 roof project underscores AirPower’s potential for broader applications in the automotive composites industry. HP Composites is already applying this technology to produce other components for the Maserati group, including side skirts, front and rear diffusers, and splitters. For some of these parts, the company has implemented fast-curing resin systems, further reducing production cycles from a couple of hours to less than 20 minutes.

The scalability of AirPower technology extends beyond the automotive sector. Mastroberti notes that the company is exploring opportunities in satellite and space applications, leveraging the technology’s ability to produce parts with varying geometries and complexities without compromising on quality.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

Smarter molding with Smart Cauls

Spintech’s Smart Caul technology can be used to create internal mandrels, bladders for hollow parts or any irregular male layup tool shape involving a sharp angle or corner.

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read More