Composites Technology Digs-In Underground

The Underground Construction Technology Conference welcomes corrosion-resistant composites for underground infrastructure.

Pipe manufacturers and rehabilitation specialists who use composites will capture no more than 1 percent of the estimated $31 billion that will be spent worldwide in 2007 on underground water, wastewater and chemical infrastructure. The inherent corrosion-resistance and long-term durability of composites, however, have earned this group a growing niche in subterranean applications and a small, but significant, presence at the annual Underground Construction Technology (UCT) International Conference & Exhibition in Houston, Texas. Sponsored by Underground Construction magazine and other industry publications and corporations, the 2007 UCT event attracted 3,000 attendees to the George R. Brown Convention Center, Jan. 30-Feb. 1, 2007, for a look at the latest in underground flow-systems technology. Composite pipe manufacturers were on hand with news about the latest in filament-wound composites and hybrid technologies for new pipe construction, but the strongest contingent focused on the largest market for composites in underground piping: trenchless rehabilitation of increasingly deteriorating municipal water and sewer pipe infrastructure.

New Construction

For new pipeline construction, two types of composite/mortar sandwich pipe were introduced, made by filament winding fiberglass inner and outer pipe laminates around a mortar core, which allows a thicker wall at less expense than building up a thick laminate wall. A polyester, vinyl ester, epoxy or polyethylene matrix is used, depending on the flow media. This type of sandwich construction was on exhibit at the conference, offered independently by Ameron International and Future Pipe Industries (FPI), both based in Houston, Texas. Ameron also touted its steel/composite hybrid pipe (see "New steel-strip-reinforced fiberglass pipe handles high-pressure oilfield applications" under "Editor's Picks," at top right), which the company says is gradually gaining acceptance for high-pressure applications.

Also on offer was a proprietary computer-controlled, centrifugal-casting construction process that produces lightweight, high-density pipes for both new construction and repairs. Compared to concrete pipe, this product, produced by Houston-based Hobas, replaces a cement matrix with thermoset resin, and exchanges steel reinforcement for fiberglass. In business for 50 years, Hobas has placed pipe in 50 countries.

Repair and Rehabilitation

In the fast-growing arena of existing pipe rehabilitation, “trenchless” systems offer in-situ repair of corroded and otherwise damaged cast iron, steel and concrete pipelines, without excavation and replacement. Currently, there are two general types of lining technology, sliplining and cured-in-place pipe (CIPP). Sliplining involves the use of a cured composite pipe, smaller in diameter than the existing pipe, which is delivered to the site in sections or (if small enough in diameter) coiled in long lengths. The new pipe is inserted and then secured in place by grout that is pumped in between the old and new pipe. CIPP features a premade, precatalyzed, but uncured (and therefore still flexible) composite sleeve, typically delivered to the installation site flat and folded for easy transport. The sleeve is installed inside the existing pipe and then, as implied by the name, is inflated and cured in place.

In the sliplining market, corrosion-resistant, thermoformable polyvinyl chloride (PVC) and high-density polyethylene (HDPE) polymers are gaining market share in sewer, storm water and potable water pipe and trenchless repair applications. The highly ductile unreinforced products are deformed into “U” or “H” shapes at the factory, prior to coiling for transportation to the installation site. The deformed liners are then winched through the host pipe and inflated with pressurized steam. The heated liners soften and expand, conforming to the host pipe walls, and then are chilled under pressure to “set” them in final form. A supplier of both products, Ultraliner (Oxford, Ala.) exhibited an HDPE liner strengthened with Kevlar aramid fiber from DuPont Advanced Fiber Systems (Richmond, Va.). The Kevlar-reinforced HDPE makes a standalone liner that, unlike liners made with neat resin only, can withstand pressure as high as 350 psi/21 bar, according to Luke Whittle, president and CEO of Ultraliner. Applications include potable water lines, distribution lines and sewer force mains, which are used where sewage must be pumped up from a lower to a higher elevation.

Jobs in progress include a 30-inch/762-mm diameter liner to repair an old, corroded steel pipe for potable water transmission in Galveston, Texas; a 15-inch/381-mm liner to repair an old, corroded cast iron sewer force main in Minneapolis, Minn.; and a liner for a winery in Northern California.

There was considerable attendee interest in a presentation by Smart Pipe Co. (Houston, Texas) on its new onsite production method for glass- and carbon-reinforced thermoplastic pipe liners used in high-pressure applications (see "In Situ Manufacturing: Pipe Relining in Demanding, Corrosive Environments," under "Editor's Picks"). The company claims its liners can operate at service pressures as high as 4,000 psi/276 bar. The system uses computer-controlled equipment set up under a temporary tent for continuous manufacturing and installation of up to 10 miles/16 km of liner from a single entry point. Lengths up to 2,000 ft/610m of 6-inch/152.4-mm pipe can be made at the factory, coiled and trucked to the installation site. Each job is customized to engineering design guides and standards, and liner materials are selected with the aid of structural analysis software.

Meanwhile, CIPP service providers showcased several significant trenchless developments. The first and still most common method consists of resin-saturated fabric made in the form of a flat tube or sleeve with a polyethylene liner, which is usually manufactured inside (liner) out, then inverted during installation as water pushes it through the host pipeline. When the sleeve is in place, it is inflated to fit against the inside wall of the host pipe; hot water or steam is then directed through the pipe to cure the resin. The UCT Conference was the forum for several CIPP introductions that vary from the original formula.

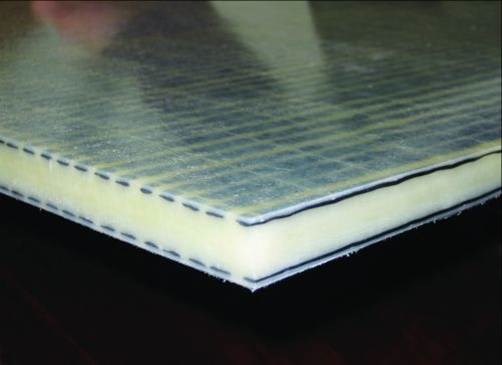

Insituform (Chesterfield, Mo.) exhibited its iplusComposite carbon fiber-reinforced CIPP liner product, introduced in late 2006 for medium and large diameter (24-inch/61-cm to 96-inch/244-cm) host pipe. The liner is made by stitching carbon tow in the weft direction over needle-punched polyester felt. This construction provides structural properties equal to or exceeding that of polyester-felt CIPP at half the wall thickness, thus optimizing flow capacity and pipe flow rate. The stiffer, less flexible sleeve is winched through the host pipe, rather than inverted. Fiberglass is used in place of carbon for weft reinforcement in applications with less demanding requirements. Fiberglass also is used in the warp direction to take the anticipated longitudinal stress of winching long lengths of CIPP. The iplusComposite product reportedly uses less resin, cures more quickly and weighs less than inverted constructions – factors which combine to make it cost-competitive, according to Insituform’s business development manager Glen Wiederholt.

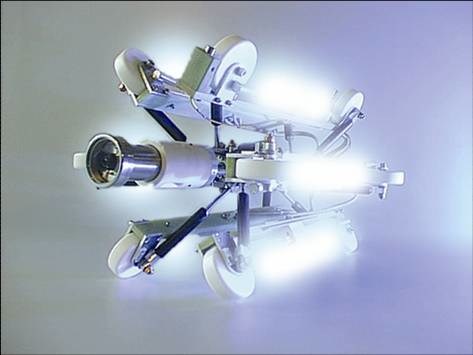

Two exhibitors highlighted UV-curable CIPP technology, which eliminates the need for hot water or steam and the equipment necessary to heat it, and ends concern about the presence of styrenated water in the flow media following cure. International Pipe Lining Technologies (IPL, San Diego, Calif.) and Reline America (Saltville, Va.) offer liners in diameters up to 48 inches/1.2m. The lining systems rely on stitch-bonded, light transparent fiberglass fabric wetout with resin formulated for ultraviolet (UV) cure. Cure is effected by a UV light “train” – a collection of UV lamps on a wheeled device (see photo, this page) – which is pulled through the pre-impregnated CIPP at a speed calculated to provide UV energy at an intensity and exposure duration sufficient to completely through-cure the laminate.

IPL’s trademarked LightStream Liner was introduced recently to the North American market after development and use in Europe, where more than 3 million ft/914,400m of pipe have been relined. The liner features several layers of Advantex glass fiber (Owens Corning, Toledo, Ohio) and is impregnated with either polyester or vinyl ester resin (the latter for wastewater applications). The product can be manufactured and installed in one piece up to lengths slightly in excess of 1,600 ft/488m. Liners are inflated pneumatically, then cured via the company’s proprietary OpenEye installation and curing system that features the Eye-Botix light chain, which is pulled through the pipe at constant speed. The system’s UV curing lamps are powerful enough to cure pipe liners up to 0.5 inch/12.7 mm thick.

A winner of Trenchless Technology magazine’s Most Innovative Technology award, Reline America’s trademarked Bluetec liner uses a system developed in the 1990s by Brandenberger Liner GmbH & Co. (Landau, Germany) that, according to Reline America, has been used by Brandenberger and its licensees to reline 5 million ft/1.524 million m of sewers and other underground pipe systems in 24 countries. Products for the North American market are manufactured in the company’s Saltville plant by spiral winding resin-impregnated fiberglass fabric into CIPP sleeves. Intended primarily for low-pressure gravity sewer applications, the product has a six-month shelf life and is shipped to the job site in containers that protect it from sunlight (refrigeration is unnecessary). At the site, a slip-sheet is pulled or winched into the damaged pipe. The fiberglass liner is then winched in over the smooth slip-sheet. Once the liner is in place, a UV light train is inserted and the liner is inflated with compressed air to fit tightly within the damaged pipe. The light train and a closed-circuit TV camera are winched through the uncured liner to document its installed condition; then the lights are turned on and the light train is pulled back through liner to effect the cure.

For pipe “point” repairs – those that remedy localized damage caused by root intrusion or separated joints – Perma-Liner Industries (Largo, Fla.) touted its patented Sectional Point Repair System, a tubular 5-mil, felt-lined fiberglass material. During installation, a felt sleeve and polyurethane inner liner are pulled over a partially inflated bladder; epoxy-saturated fiberglass mat is wrapped around that package. After the package is pulled into the host pipe and positioned in the damaged section, the bladder is inflated to hold the liner against the original pipe during an ambient-temperature cure. Following cure, the bladder is deflated and pulled out of the line. Perma-Liner offers custom-packaged repair tubes from 2 ft to 30 ft in length (0.6m to 9.1m) and 6 inches to 54 inches (152.4 mm to 1372 mm) in diameter. In the majority of cases, the company claims, repairs can be done without resorting to by-pass pumps. Instead, Perma-Liner supplies a “flow-through” bladder, which permits water or other liquids to continue to flow through the pipe during installation, inflation and cure.

CIPP growth was confirmed by exhibitor statistics for resin sales. Resin manufacturer AOC (Colliersville, Tenn.) reported a 10 to 15 percent annual growth in this market. AOC, Ashland (Dublin, Ohio) and another UCT exhibitor, Interplastic (St. Paul, Minn.), are significant suppliers for CIPP exhibitors that included Insituform, CIPP Corp. (Hudson, Iowa) and the Novapipe division of Lantor Group (N. Smithfield, R.I.).

While going underground may seem less glamorous than going into space, expect composites to play an increasingly important role in the infrastructure market, especially as aging water supply and wastewater systems in the U.S. and around the world reach the end of their design lives.

Read Next

New steel-strip-reinforced fiberglass pipe handles high-pressure oilfield applications

Hybrid technology positions composite pipeline to compete with steel in land and sea oilfields.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More