Fastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Choosing the right fastener for components or assemblies involving composite materials can be a complex task. Navigating through terminology barriers and understanding the diverse world of materials and fastening functionality is crucial. In this article, we explore how to simplify this process, drawing insights from a collaboration between Bossard (Zug, Switzerland) and thermoforming companies to develop fastening solutions for thermoplastic aircraft interior panels.

Terminology barriers, example pathway for fastener selection

How do you decide on the “right” fastener type for a component or assembly involving composite and plastic materials in a time-efficient way? To define which materials and concepts a fastener type is suitable for requires an understanding of the materials involved, their forming processes and the required fastening or assembly functionality.

Take an aircraft interior panel, for instance. Describing it merely as an “aerospace composite” material oversimplifies the rich array of available materials and processes. Similarly, the term “aerospace fastener” lacks specificity about the materials a fastener best suits and the functional aspects of its fastening. Fasteners such as insert studs, rivet studs, surface bonding fasteners and welded fasteners may all be suitable for aerospace applications yet differ significantly in terms of the materials they can fasten and their functionality.

The trouble with navigating the fastening world lies in how fastener products are categorized, which often uses terminology specifically relevant to fasteners instead of the materials for which they are best suited. However, terminology specific to composite materials tends to have limited relevance in navigating fastener categories. For example, how do you know if a surface bonding or ultrasonically weldable fastener is an applicable fastening option for thermoformed laminate materials, without a detailed understanding of surface bonding or ultrasonic welding in the context of fastener installation? If your world is polymer matrix properties, fiber reinforcement architectures and processing parameters, how can you navigate a world that talks about assembly strategy, fastening direction, tightening torque expectations and target preloads?

Contacting a fastener supplier or distributor for advice and guidance is often an efficient and successful first step; but further streamlining is achievable by presenting applications in a way that allows simple, quick navigation toward relevant options. Here, we illustrate the important aspects of such a pathway for refining fastener selections using the example of a thermoplastic aircraft interior side panel.

Fastening requirements

First, it is helpful to define the fastening requirement. Do you want to create a fastening point for a composite or plastic component, ready for subsequent assembly operations down the line? Or do you want to directly fasten components onto or into your composite or plastic component?

For our example, the requirement is to create fastening points — specifically, to provide threaded connection points on a composite panel. Thus, we will steer toward technologies that provide a means of installing fastening connection points, instead of ones that are used to directly fix components together. Fastening technologies are relatively easy to categorize using these terms, and the terminology is relatively simple so that everyone can communicate using the same language.

Material concepts

Factors relating to the materials involved can affect fastener type suitability, but the relevance of these factors often depends on the fastener type under consideration. To break this cyclicity and avoid overly detailed conversations during early filtering, we can define composite and plastic materials generically as:

- Unreinforced polymers.

- Discontinuous fiber-reinforced polymer materials.

- Continuous fiber-reinforced polymer laminates.

- Sandwich materials.

- Nonwoven and fibrous materials.

In our example, the aircraft interior panel material is a continuous fiber-reinforced polymer in a laminate architecture. By defining the material concept in this straightforward way, we can quickly spotlight a set of relevant material considerations:

- How will the fastener integrate into the manufacturing process chain?

- How do the materials affect the fastening integration or installation?

For instance, integrating fasteners within the continuous reinforcement material prior to or during thermoforming could cause undesirable process complexity, such as cutting or displacing fibers that may undesirably affect mechanical performance. In other words, continuous fiber reinforcements can present challenges to co-process fastener integration that one may wish to avoid.

Meanwhile, it requires only basic understanding of a fastening technology to determine whether it uses co-process or post-process installation. By simplifying both the material and the fastening terminology, it is possible to quickly and easily see what matches and what doesn’t. In our example, fastening selection should focus on post-process technologies, unless we wish to get into the challenges of integrating fasteners into continuous fiber-reinforced materials/manufacturing processes.

Detailed requirements

At this point, in order to identify relevant fastening technologies, we need to define more details about the fastening strategy, the materials involved and the forming process. For our continuous fiber-reinforced laminate example, we define the application as follows:

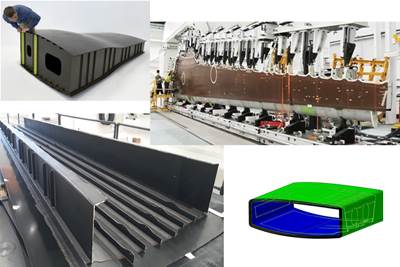

- The generic application is an aircraft interior side panel.

- The fastening strategy is to provide a threaded stud on the reverse (non-visible) side of the panel for attaching a polymeric window surround using a threaded nut.

- The fastening requirement is a blind, non-visible, externally threaded connection point — blind meaning the installation/fastening occurs from a single side of the component — with an ability to withstand around 500 newtons of pull-off force.

- The panel is a continuous fiber-reinforced thermoplastic material, and fastener installation must occur after the forming process to avoid disrupting the reinforcement architecture.

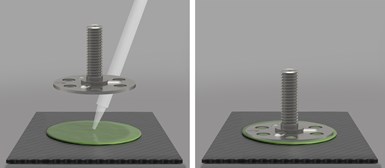

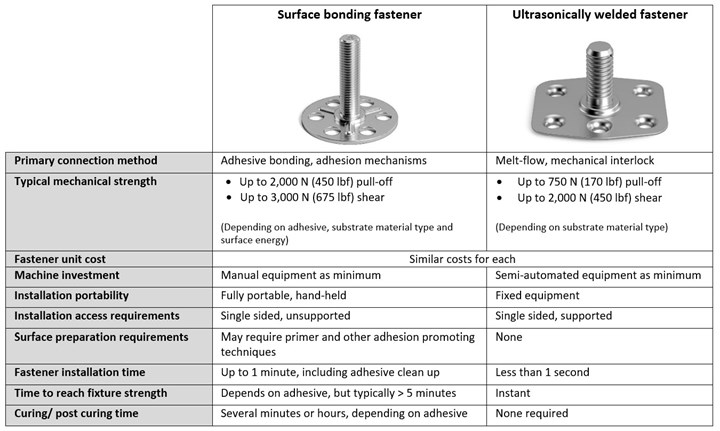

Factors to consider in deciding between surface bonding fasteners (e.g., bigHead) and ultrasonically welded fasteners (e.g., Multi-Material MM-Welding) for a thermoplastic composite aircraft interior panel.

Further sorting factors, downselecting

Looking at our example, we can start to see multiple factors that can affect our decisions about which fastener to use. The question is, which of these factors are most important, especially if fastener item cost is not the sole decisive factor? In our example, we have narrowed choices down to either a surface bonding fastener or an ultrasonically welded fastener.

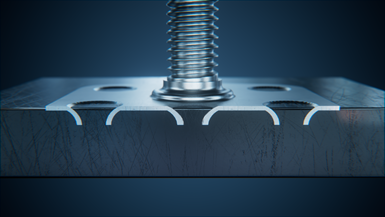

Example of an ultrasonically installed fastener, showing the welding process (top) and resulting mechanical interlocking (bottom).

Here is where even simplistic application information can help. For example, knowing we are working with a thermoplastic material helps us set a relevant performance expectation. Given the availability of specialist adhesives and surface preparation techniques, we can expect a reasonable level of mechanical performance for either technology.

However, because we know the application is aerospace, a mechanically interlocked connection may offer a simpler route to performance assurance and certification. Adhesives require time to cure, whereas ultrasonic installation is instantly loadable, so we should consider process time implications. Access constraints can also be a critical factor. Although interior panels are typically easy to present to an automated adhesive applicator or ultrasonic machine for fastener installation, this should be double-checked before making a final downselect.

Making the final decision

A decision based purely on connection method qualification and fixture time is unlikely; the final decision will depend on consideration of equipment investment, mechanical performance and durability, overall process time implications, access constraints and approval or certification strategies. Also, design, manufacturing and assembly operations may involve different stakeholders — so a final decision requires their input.

Furthermore, to make this decision requires consideration of the entire value proposition, including productivity and the total cost of ownership (TCO). By taking a holistic view of fastening and considering all the factors that are relevant at the initial design stage, within the manufacturing process and at the final assembly operation, it is possible to calculate and positively influence productivity and TCO. These are among the key principles in Bossard’s Assembly Technology Expert Education portal, aimed to help individuals gain knowledge in assembly technology.

Ultimately, the final decision on which fastening strategy or product to use depends on multiple factors — there is no one-fits-all solution, and there are so many different options to consider. However, as we have outlined above, defining the application details even in a relatively simplistic way can streamline the selection process, highlight relevant decision factors and identify where stakeholder input might be needed.

About the Author

Dr. Lawrence Cook

With a wealth of experience in bonding fasteners and composites manufacturing, Lawrence works as a development engineer at bigHead, part of the Bossard Group. Based in Cranfield, U.K., Cook works together with global teams on composites and plastics fastening projects. Follow Lawrence on LinkedIn.

Related Content

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreGuidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Read MoreRead Next

Molding in fasteners to CFRP parts

Placed into the mold prior to RTM, compression or injection molding/overmolding, this specially-shaped fastener enables composites to be fastened with standard methods used for metal parts.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

Read MoreSolar-powered photonic cooling enables energy-saving coating

Passive cooling technology can reduce interior temperatures 5-13°C, offering weight, cost and CO2 benefits for cars, construction, aircraft and more.

Read More