Revisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

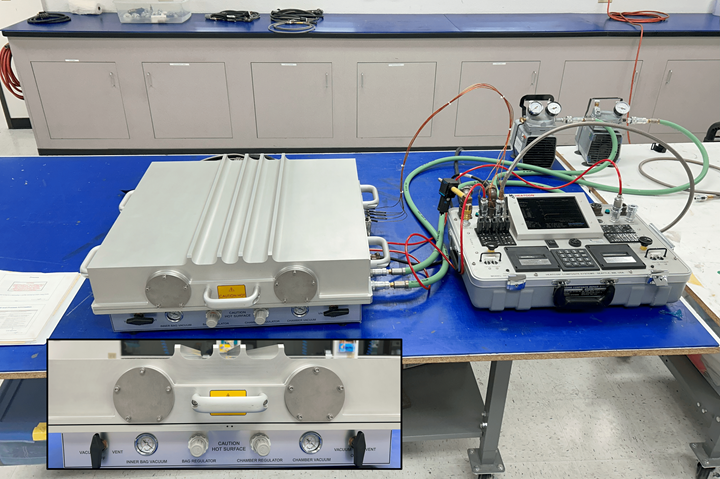

Figure 1. Vacuum chamber (left) and hot bond controller (right) along with a vacuum source for the inner bag and chamber are all connected and ready to run a double vacuum debulk (DVD) process. Inset photo shows a closeup of the vacuum controls and gauges. Source | Abaris Training Resources

I was first exposed to the double vacuum debulk (DVD) process in the early 1990s while viewing a demonstration video produced by the U.S. Navy. At the time, I was intrigued with the out-of-autoclave (OOA) process of which the Navy claimed provided a “near autoclave quality” repair patch. In the demo, the technician had a vacuum bagged wet layup CFRP patch with a “wedding cake” configuration (big ply down, smaller plies ascending) stacked on a heated plate with a bell jar on top that was sealed to the bag containing the patch. There was no breather under the bag so that you could see the underlying laminate. Vacuum was slowly applied to the bell jar until a pressure differential was created between the inner bag and the jar. At that point, the camera closed in on the patch inside the inner bag, revealing small bubbles percolating around the edges of each ply in the stack as the patch was heated to a designated isothermal temperature — it was held for a period of time until the bubbles disappeared. Then the vacuum connection to the bell jar was released, venting the jar to the atmosphere, enabling the inner bag to compact the patch with full atmospheric pressure (~14.7 psi at sea level). The patch was later cured under vacuum and tested for the void volume fraction (ref. ASTM D3171) which was determined to be far less than 1% — much better than was achievable using single vacuum bag (SVB) processes at the time.

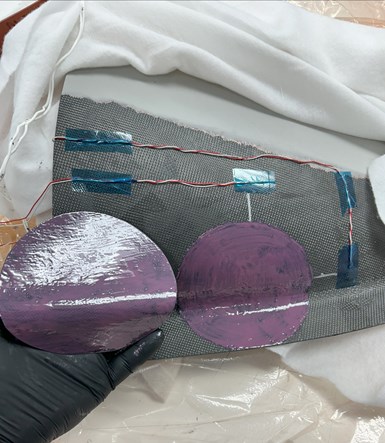

Figure 2. Vacuum bag, breather, bleeder and repair stack during leak check. Note that the thermocouples (TCs) are plugged into a pass-through block inside the chamber. Source | Abaris Training Resources

Since then, the DVD procedure and equipment have greatly improved the process (read CW’s “Double bagging through three decades”). Instead of a bell jar, a vacuum-regulated chamber is used, along with a heat blanket, thermocouples (TCs) and a hot bonder to control the process (Fig. 1). Larger sized, self-contained floor equipment is also available1.

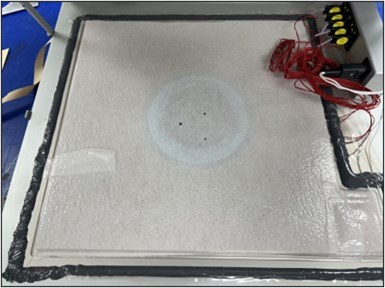

Inside the chamber you will find a series of materials that include a breather (for insulation), a heat blanket, TCs, an aluminum caul plate, a non-porous Teflon-coated fabric (TFNP), a layer of porous Teflon-coated fabric (TFP), the patch layup, TFP, bleeder layer(s), TFNP (perforated on 2-inch centers), more breather and a vacuum bag sealed to the plate surface (Fig. 2). (See “Understanding vacuum bagging layers ...”). Vacuum is drawn to the bag and leak tested. The chamber (box) is closed and sealed to the plate surface — after which the process can begin.

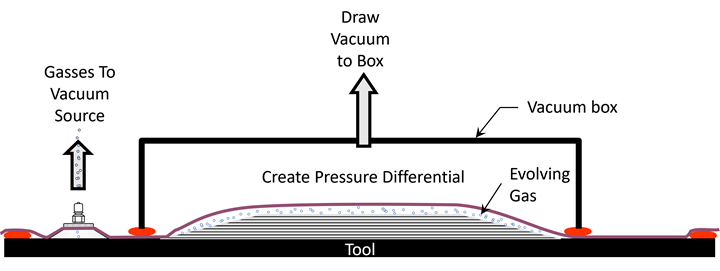

Figure 3. By pulling vacuum inside the chamber, a differential is achieved and the layers under the bag are no longer under pressure yet are still under vacuum. This enables the resin in the repair laminate to “degas” as if it were in a vacuum chamber. Heat is applied during the process to lower the resin viscosity and promote resin movement within the patch during the degassing event. Source | Abaris Training Resources

The purpose of the DVD process is to remove gases from the laminate prior to fully compacting it, which brings it to an advanced stage of cure (B- or C-stage) with minimal voids. Knowledge of the resin’s viscoelastic (VE) properties at different isothermal temperatures is necessary to develop process recipes for resins that have not already been established. For example, industry has VE data for the Loctite (Hysol) EA9390 resin which requires a temperature of 49-55°C for a period of 30-60 minutes to degas, depending on the laminate thickness (thicker laminates may require multiple debulks). Other liquid and prepreg resins would require a different time and temperature based on their unique VE properties.

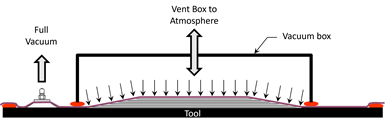

Figure 4. Venting the chamber allows the inner vacuum bag to pull down tight against the patch, effectively compacting the freshly degassed layers and bringing the laminate to the desired state of cure. Source | Abaris Training Resources

Figs. 3 and 4 illustrate how the DVD process works. First, the vacuum to the inner bag with the patch is turned off using the inner bag supply valve. Then vacuum is slowly drawn in the chamber until it is within 1 Hg inch of the value of the inner bag (per the gauge reading), creating a slight pressure differential between the chamber and the inner bag. Vacuum is reapplied to the inner bag and maintained for a specified (pre-gel) time at the isothermal temperature determined by the VE profile or as given in the repair instruction. After the time has elapsed, the chamber is vented to the atmosphere and the patch is debulked within the inner bag until the desired state of cure is reached.

Figure 5. The B-staged patch laminate and the structure to be repaired are coated with a paste adhesive prior to application of the patch. The patch is then positioned so that the fiber angles match and the patch is cured with a heat blanket using a vacuum bag process. Source | Abaris Training Resources

After DVD processing, the patch can be removed from the chamber and cobonded (Fig. 5) or cured to a shape on a separate mold and secondarily bonded to the parent structure as needed.

Development of a SVB process to replace DVD has been examined for many years (since 2016) by a commercial group under an SBIR-STTR program for the Department of Defense. The goal is to produce an equivalent or better-quality process that is suitable for larger repairs, on or off aircraft, that requires fewer resources and is less time-consuming. The status of this effort is unknown at this time.

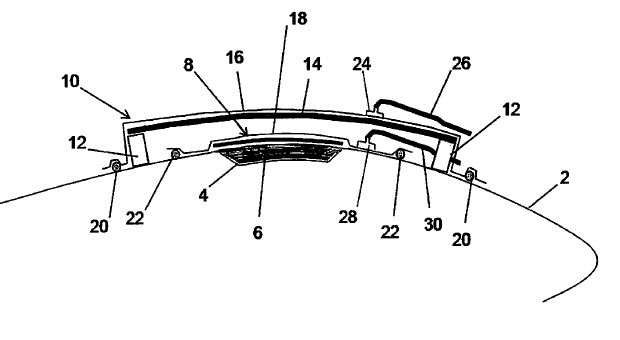

In 2010, the Boeing Co. filed a patent2 for an in-situ DVD method that applies to contoured surfaces. While the basic concept is the same as described above, the on-aircraft capability allows for both debulking and curing the patch in place in one process (Fig. 6). Optional setup using an inflatable bladder in the chamber, along with specific details, can be found in the patent document.

In addition to using the DVD process for composite repair patches, it is imagined that the basic concept of extracting volatiles and gases prior to compacting composite laminates is possible. I can envision using an adapted version of this process to build small structural panels and other items such as ballistic armor plates, doors and hatches, plaques, etc. without the overhead of an autoclave. The possibilities for innovation are endless.

Figure 5. This illustration shows the basic concept of the in-situ DVD setup. Source | Boeing/U.S. Patent office

References:

- Heatcon Systems, (Seattle, Washington) HCS7600 series DVD tool. https://www.heatcon.com/product/hcs7600-double-vacuum-debulking-chamber/

- US Patent Publication Number US2012/0080135 A1, published in April of 2010

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

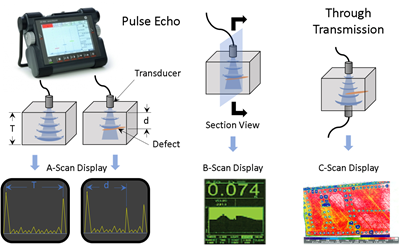

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More