Mantis Composites developed its continuous fiber, fused filament fabrication (FFF) based 3D printing technology to provide the aerospace and defense industries with an option for small, complex, highly tailored, high-performance components for aircraft and other vehicles. Today, Mantis Composites continues pushing the envelope further with R&D in space components and ceramic matrix composites (CMC). Photo Credit, all images: Mantis Composites

According to Ryan Dunn, CEO of Mantis Composites (San Luis Obispo, Calif., U.S.), he and fellow co-founders David Zilar, COO, and Michael DeLay, CTO, recognized a gap in the composites market for producing highly detailed, high-performance aerospace and defense parts using lightweight carbon fiber composites.

“There is a lot of work being done in increasingly larger aerospace structures — aircraft fuselages, and that sort of thing — and even in 3D printing with large-format additive manufacturing, but we realized there was a need for smaller, highly intricate, even customized parts for engines, brackets or other areas that other composites companies weren’t taking on,” he says.

Dunn, Zilar and DeLay met while they were students at California Polytechnic State University, and combined their experience and education in composites, 3D printing and business to develop what would become their company’s custom-designed, five-axis, continuous fiber 3D printer — as well as a business plan and the industry connections needed to reach their goals.

In addition to printing highly complex components, services offered include custom design/engineering, post-processing, bonding and surface treatment.

Mantis Composites was officially founded and moved into its own facility in 2014, and the team worked to optimize its technology for a few years before ramping up in 2017, Dunn explains. “When asked to measure ourselves, we like to say we’ve grown to 10 people and 24 robots,” he says.

Mantis Composites’ technology uses a fused filament fabrication (FFF) 3D printing system, which essentially entails extruding a filament made up of a pre-impregnated, continuous fiber/towpreg. The company also developed its own specialized design software to model and print parts with the accuracy needed to create detailed components to meet aerospace specifications. Parts can be printed on a range of commercial materials, though Dunn notes mostly carbon fiber and high-temperature thermoplastics like polyetheretherketone (PEEK) are used.

Today, operating three additive manufacturing (AM) cells with a maximum print volume of 18 x 20 inches, Mantis Composites offers custom design/engineering, printing, postprocessing, bonding and surface treatment services for each of its projects. Fiber placement accuracy is said to be within ±0.015 inch (±0.4 millimeter) tolerance, and lower after postprocessing such as machining or sanding.

Much of the company’s commercial and R&D work remains within the realm of relatively small, detailed, high-performance components for aerospace, defense or space applications, at volumes of up to several hundred of each part per year. “We specialize in ultra-high-temperature-capable carbon fiber thermoplastic composites with high fiber volumes,” Dunn explains. Parts are highly engineered for strength, stiffness and thermal capabilities, and completed projects include parts for aircraft landing gears, weapons mounting components, brackets and gearbox housings.

Case study: U.S. Air Force beam and bracket

Specialized design software is used for accurate modeling and printing. This image shows the fiber path for printing a carbon fiber/PEEK bracket demonstrator for the U.S. Air Force.

Between 2018-2020, Mantis Composites worked with the U.S. Air Force (USAF, Washington, D.C., U.S.) on a demonstrator beam and bracket structure for use in an optical space telescope. The original structure comprised an Invar connector fitted to a tube-shaped truss structure. Funded by NASA’s Jet Propulsion Laboratory (JPL) as well as private sector customers, the project aimed to replace the Invar connector with an integrated composite assembly that reduced weight and exhibited a low CTE (coefficient of thermal expansion) more suitable for thermal environments in space.

Using continuous Hexcel (Stamford, Conn., U.S.) IM7 fiber and Solvay (Alpharetta, Ga., U.S.) PEEK, Mantis Composites printed the component, which was then bonded to a truss structure. “What we produced is a standardized, integrated product that is thermally optimized for space,” Dunn says.

The final bracket is a hollow, tube-shaped structure that weighs a tenth of the original Invar part, with eight times lower thermal expansion.

One challenge to the project, however, was controlling the fiber direction, particularly in the printing of the hollow, tube-shaped part. Ultimately, the completed part was a similar shape to the original Invar part, at a tenth of the weight, with eight times lower thermal expansion.

Next steps? “Since then, we’ve been moving forward with very similar projects for customers, having demonstrated the capabilities,” Dunn says.

R&D and future efforts

Research and development focuses include continued optimization of the process, new bonding and integration techniques, and materials for extreme temperatures, such as carbon/carbon and silicon-carbide ceramic matrix composites (CMC).

Related Content

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAirbus presents unmanned Wingman concept

Fighter jet model unveiled at ILA Berlin, made from an iron structure and composite outer skin, will deliver more tactical options, supporting future combat missions.

Read MoreRead Next

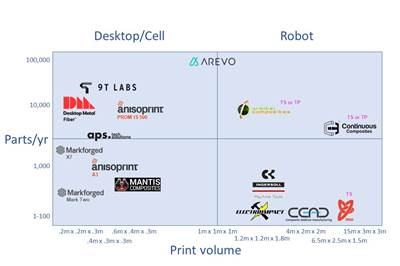

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)