Share

Read Next

It’s no secret that composites are expensive and tough to work with, which means if you’re still relying on manual methods for nesting and cutting, you’re probably wasting large amounts of time and material. Technical textiles and composites are increasingly used across a number of industries, and the complexities of these products demand agility and quick product optimization in order to constrain material and labor costs.

For a more agile and efficient process, many composites manufacturers are beginning to digitally transform their supply chains by implementing the latest automated nesting and cutting solutions. With automated nesting and cutting solutions, you can maximize material utilization by getting the best nest and cut possible.

This video shows Gerber Z1 automatic cutting machine cutting a variety of materials.

Software is Key to Cutting Efficiency

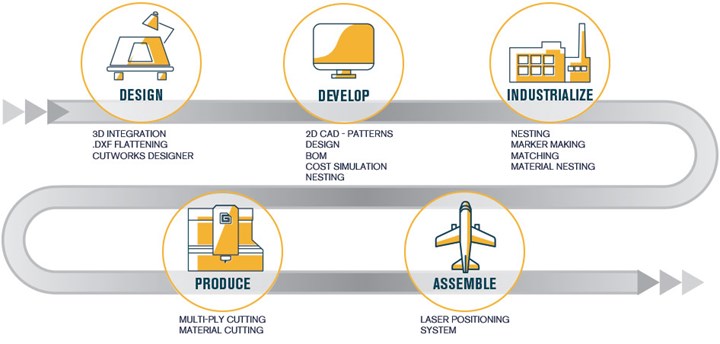

While having a fast and accurate machine is central to automated cutting, the software behind it is key to having a truly efficient cutting system. Gerber Technology addresses this with a suite of software and hardware solutions for every step of the manufacturing process including pattern design and digitizing, materials planning and management, nesting, cutting machine control and monitoring, quality control, and assembly, as well as the ability to seamlessly share data across all these applications. Here’s a quick snapshot of what you need to have a fully integrated system.

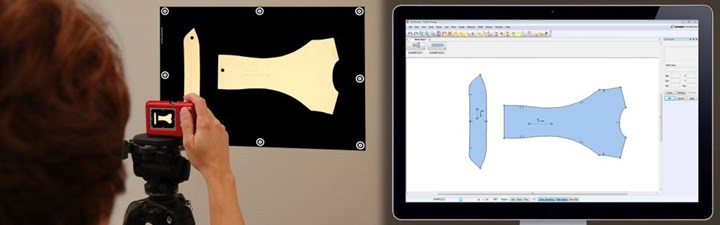

Design – Fabricators converting from a manual cutting operation need a way to digitize their existing physical patterns or digitally create new ones. The next step is working directly from 3D product CAD files to, for example, flatten out a reinforcement shape so it will precisely fit a contoured mold surface.

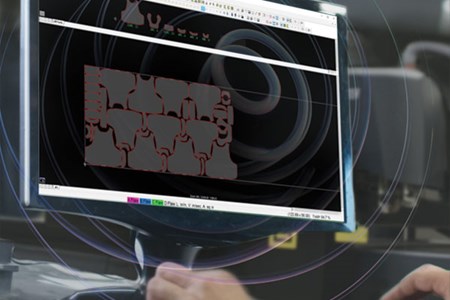

Good nesting software reduces preparation time for new jobs and can substantially improve material utilization.

Nesting – Manually nesting patterns on a roll of material creates excessive scrap. Good nesting software can automatically nest a pattern, or multiple patterns, for the most efficient use of material. This gets jobs into production faster, minimizes material waste and can be very beneficial in kitting operations.

Machine Control – Once the nesting program is transferred to an automated cutting machine, material shapes will be cut much more accurately than is possible than with manual cutting which improves quality and reduces material waste and labor.

Materials Management – Through the combination of a nesting program and cutting machine monitoring you can know exactly how much material you need on hand for upcoming work and validate how much you actually use by material type or for any given product. This is enormously useful information for production planning and cost control.

Software Applications for the Job

Gerber addresses these needs in a modular way so that a suite of software applications can be applied to a user’s particular needs. For example, CutWorks® and AccuMark® are next-generation design software applications that allow data to be shared throughout the workflow. Its Designer module is built on the AutoCAD platform and is used to create, digitize and edit parts. It’s ComposiNest™ nesting module is designed specifically for the composites industry. It includes advanced nesting algorithms to enhance ply placement for maximum material utilization. It can automatically generate nests without human intervention and integrates with Gerber cutting machines as well as machines from other manufacturers.

Integrated digitizing tools simplify the capture of existing physical templates.

CutWorks also includes a Database Administrator module that:

- Tracks production data of cutting machines including materials consumed, parts and jobs processed, and machine operators.

- Creates production schedules and monitors work in process.

- Generates customizable reports.

Gerber also has a range of packages aimed at other applications such AccuPlan™ which is a spread and cut planning tool for improved material and labor utilization for applications such as furniture, upholstery and automotive interiors. Costs can be tracked easily, as well as material weight. This software helps reduce labor and material costs by being able to adjust quickly to work order needs and improving the shared understanding of available inventory. For integrated composites manufacturers that cut a range of materials, this facilitates better utilization of both cutting equipment and people.

A major advantage of having all these applications running on a common platform is the ability to pass data seamlessly through a fully integrated workflow. It improves efficiency and leaves less room for error. Throughput can be boosted by up to 50% through optimization of the entire cutting process. It maximizes efficiency by being able to analyze available fabrics for the most efficient yields. It also achieves full automation in the nesting process by using special marker placement tools which can help save up to two weeks of development time. An integrated system also streamlines the transfer data to production and accelerates workflow while reducing cost and increasing agility.

Still another group of applications can be used to augment other manual aspects of composites fabrication are the laser templating products from Virtek Vision. Virtek is a part of the Gerber Technology family suite of Laser Projection and Vision Systems, both owned by American Industrial Partners. The two-combined compliment the manufacturing process with Gerber cutting & kitting of carbon fiber, and Virtek with laser projection for hand- layup, and assembly of composite material.

Virtek 3D Vision Positioning System

For example, the Virtek 3D Vision Positioning System projects a virtual laser template onto complex 3D molds and parts to guide operators through the process of part fabrication. It can be used to guide composite layup, reinforcement placement, tooling modifications and assembly positioning. It can even be used for in-process or final inspection purposes. Accurately projected laser templates can eliminate the need for blueprints, physical templates and manual measuring. Use of technology like this can eliminate expensive tooling, stop costly errors, and significantly cut time to market.

Ongoing Support

Another important factor to consider is that Gerber can provide support throughout the whole process. Gerber offers several advanced IoT Remote Support solutions, such as GERBERconnect™, to help quickly solve equipment or software issues manufacturers may encounter. Gerber’s Remote Support predictive maintenance solutions monitor data and machine performance to detect issues before they impact production. With Remote Support solutions, field service technicians can access your system from anywhere in the world, allowing them to diagnose, troubleshoot, install software and solve problems without ever having to set foot in the facility.

Not only will manufacturers who leverage digital technology be able to work faster and more efficiently, they’ll be able to take their products to the next level with precision nesting and cutting that will greatly reduce material waste, cut costs and minimize human error. These solutions enable composite manufacturers to adapt more quickly to industry changes, putting them in a better position for success in the long run.

Please go here for more on Gerber Technology solutions for the composites industry.