Increasing Shear and Torsional Properties with Carbon Fiber Double Bias Fabrics

While stitch-bonded carbon fabrics are used successfully as direct replacements for traditional 0°/90° woven versions, this article will concentrate on their use in increasing in-plane off-axis (in this case ±45°) laminate properties.

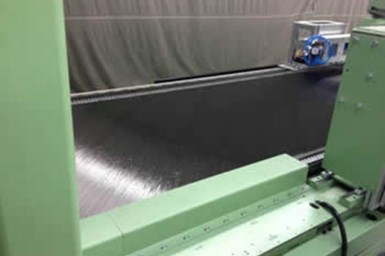

C-BX material is manufactured on a LIBA MAX 5 machine.

Carbon fiber reinforced composites are being increasingly used in applications requiring low weight with high strength and stiffness. In many widely adopted out-of-autoclave (OOA) processes such as vacuum infusion processing (VIP or VARTM) and resin transfer molding (RTM), carbon fiber fabrics are most commonly used for rapid laminate thickness build up. Traditionally, these fabrics have been woven in nature, either plain, twill, or satin weaves depending on the level of drapeability and properties required for a given application. However, woven fabrics do impose restrictions such as low composite mechanical properties due to fiber crimping, low stability, and lack of off axis reinforcing options. In order to improve on these shortcomings, stitch-bonded multiaxial carbon fabrics were developed.

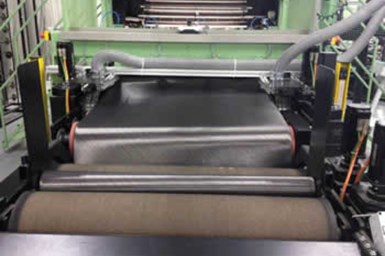

After going through the stitch head, C-BX material is put into roll form.

While stitch-bonded carbon fabrics are used successfully as direct replacements for traditional 0°/90° woven versions, this article will concentrate on their use in increasing in-plane off-axis (in this case ±45°) laminate properties. Stitch-bonded fabrics are ideal for this type of reinforcement, as the “double bias” fabrics provide non-crimped, ±45° aligned fibers directly off the roll with no skewing required.

Orienting fibers in the ±45° double bias directions are key to strengthening and stiffening laminates against in-plane shear stresses (beam shear webs, etc.) or torsional loading (as seen in driveshafts/torque tubes, etc.). They are also required orientations for creating “quasi-isotropic” laminates (close to isotropic, meaning the same properties in all directions) which may be required when specific loading conditions are not known. Below is a comparison of the in-plane shear modulus between 0°/90° glass and standard modulus carbon woven fabric laminates and ±45° double bias stitch-bonded fabrics:

| Reinforcement Type | Fabric Type | Matrix Resin | Fiber Volume Ratio -Vf (%) | In-Plane Shear Modulus – Gxy (Msi)* |

|---|---|---|---|---|

| E-Glass | 7781 - 8-Harness Satin Weave |

5245C Epoxy | 45% | 0.77 |

| E-Glass | E-BX 1200 - ±45 Double Bias Stitch-Bonded |

INF114/210 Epoxy | 45% | 1.48 |

| SM Carbon | AGP370 - 5-Harness Satin Weave |

3501-6S Epoxy | 62% | 0.94 |

| SM Carbon | C-BX 1200 - ±45 Double Bias Stitch-Bonded |

INF114/210 Epoxy | 54% | 3.86 |

*Global coordinate system is set by the dry fabric roll dimensions: x - roll length, y - roll width

**Physical and mechanical data or woven composites taken from "Engineering Mechanics of Composite Materials" I.M. Daniel & O. Ishai - 2nd Edition, Table A.5

As can been seen above, the shear modulus is increased by almost 2 times for the glass laminate when orienting the fibers at ±45°, and over 2.5 times that when switching to carbon fiber, even at slightly to moderately lower fiber volume fractions.

VectorUltra™ carbon fiber double bias reinforcement fabrics are available in a wide variety of areal weights (see table below for standard product listing) to meet any application

VectorUltra ™ Carbon Fiber Double Bias Products

| Product Code | Total Weight | 0° | 90° | ±45°/±60° | CSM | Veil/Core | ||||

| Longitudinal | Transverse | Double Bias | Weight | Weight | ||||||

| oz/yd2 | g/m2 | oz/yd2 | g/m2 | oz/yd2 | g/m2 | oz/yd2 | g/m2 | oz/yd2 | oz/yd2 | |

| C-BX 0300 | 2.94 | 100 | n/a | n/a | n/a | n/a | 2.94 | 100 | n/a | n/a |

| C-BX 0450 | 4.46 | 151 | n/a | n/a | n/a | n/a | 4.46 | 151 | n/a | n/a |

| C-BX 0600 | 5.94 | 201 | n/a | n/a | n/a | n/a | 5.94 | 201 | n/a | n/a |

| C-BX 0900 | 8.91 | 302 | n/a | n/a | n/a | n/a | 8.91 | 302 | n/a | n/a |

| C-BX 1200 | 11.80 | 400 | n/a | n/a | n/a | n/a | 11.80 | 400 | n/a | n/a |

| C-BX 1800 | 18.37 | 623 | n/a | n/a | n/a | n/a | 18.37 | 623 | n/a | n/a |

| C-BX 2400 | 24.11 | 818 | n/a | n/a | n/a | n/a | 24.11 | 818 | n/a | n/a |

Read Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)