JEC World 2019: Kordsa

Kordsa has, in a just a few short years, transformed itself into a major supplier in the composites supply chain.

Kordsa (Istanbul, Turkey) has, in a just a few short years, transformed itself into a major supplier in the composites supply chain, and at JEC World 2019 it occupied a large, highly visible stand. Kordsa CEO Ali Caliskan sat down with CW and outlined his company’s goals. First, however, Caliskan noted that Kordsa is part of a larger organization that has a long history in the tire reinforcements business. In 2014, in an effort to diversify, the company expanded into composites, focusing on the manufacture of honeycomb cores, fabrics, prepregs and other fiber-based reinforcements. Since then, Kordsa has worked hard to establish a presence not just in Europe, but North America as well. “We are seeking balance between the market in North America and in Europe,” Caliskan said. “And we look for synergies to exchange information between the two.”

To that end, Kordsa in February acquired U.K.-based Advanced Honeycomb Technologies and, in late 2018, U.S.-based Fabric Development Inc. (FDI) and Textile Products Inc. (TPI). Going forward, Caliskan says Kordsa has plans to expand into composites fabrication operations, either via organic or acquisition growth. “We continue to search for companies that are a good fit for the Kordsa strategy,” he says.

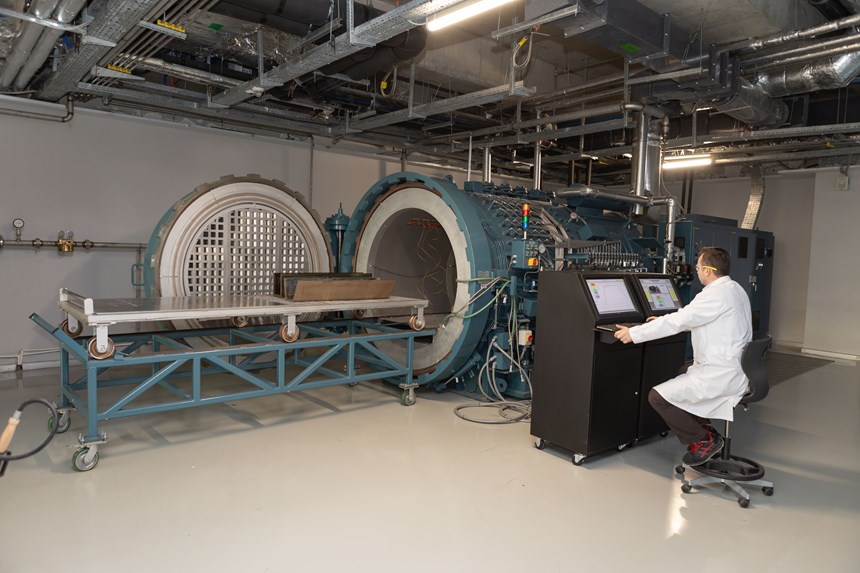

Kordsa is building a technical center in Turkey that will offer fiber placement, autoclave, testing, prototyping and additive manufacturing services. In addition, the company is working on its own automated fiber and tape placement technology. Caliskan also said the company is looking at establishing similar technical centers in the U.S. and Europe.

“We want to grow in this industry,” Caliskan said. “We are making a second Kordsa that might, in a decade, be larger than our tire business.”

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

.jpg;maxWidth=300;quality=90)