Primary structure repair: The quest for quality

Composite airframes on commercial craft drive development of automated repair technology and industry-wide repair technician certification.

As The Boeing Co. (Chicago, Ill.) delivered its first 787 Dreamliner to All Nippon Airways in September, and as Airbus (Toulouse, France) moved its A350 XWB closer to production-readiness, the prolonged debate about what is needed to repair these aircraft continued. Although the 787 and A350 are the first commercial aircraft to feature composites in fuselage primary structures (that is, those necessary to sustain flight), composites have been used and repaired in some primary structures (e.g., vertical and horizontal tails) for more than 25 years, with good long-term service results. But there is a caveat: “Most of these have been bolted repairs, or if bonded, very limited in size, rarely greater than 18 inches [457 mm] in diameter,” says Mike Hoke, president of Abaris Training Resources Inc. (Reno, Nev.), a provider of composite repair training services. Something much more ambitious, however, is envisioned for wing and fuselage repairs on these new aircraft. On the 787, for example, Justin Hale, previously its chief mechanic, says Boeing is developing thick bonded repairs up to 1m2/10.8 ft2 in size.

This is significant, Hoke explains, because although most 787 carbon composite fuselage structures are typically on the order of 20 plies thick, some of them range as high as 75 to 100 plies. Although bonded repairs to structures of this thickness and greater have been successful, they are time consuming and demand a very high level of quality assurance. Hoke adds that the longstanding quality assurance issues for bonded structural repairs to composites are increasingly challenging as structures become more optimized and unitized. “How can we ensure and certify that the repair has been done with the best recommended practices and highest quality possible, so that the adhesive bond will deliver the precisely designed performance for the life of the aircraft?” he asks.

The question is a fair one. Although the quality of the repair is still largely dependent on the individual composite repair technician’s experience and skill, only the repair workshop, not the individual who makes the repair, must be certified. And yet, with these new aircraft, the stakes for bonded structural repairs are higher. When a catering truck dings an aluminum fuselage panel, the damage is clearly visible, but the same impact on a composite fuselage could initiate subsurface delamination that extends to integral stiffeners but show no visible exterior damage.

These issues are stimulating both debate and development. One debate concerns whether or not bonded structural repairs will be approved for 787 and A350 fuselage primary structures (see “No disagreement on bonded repairs,” at the end of this article or under "Editor's Picks," at upper right). Another subject of debate is the increasing number of new technologies now in development aimed at improving process control. Automated repair technologies appear to be gaining momentum, with the goal of reducing the cost of labor and the risk of human error. Other new technologies include laser-based methods for repair-surface preparation; novel heating methods, such as induction heating and conductive patches; health monitoring of bonded composite repairs (aka “smart patches”); and an industry initiative to develop a composite repair technician certification, similar to the system in operation for nondestructive inspection (NDI) technicians.

Eliminating human error

The research and technology division of Airbus’ parent company, EADS Innovation Works (IW, Ottobrunn, Germany), is developing an automated structural repair process, continuously digital from damage recognition through repair patch creation and application, to final quality assurance, with no gaps that might allow for human error. According to Matthew Beaumont, EADS IW’s head of operations for Composite Technologies, certifiable quality in structural bonding is the destination, and automation is the only way to reach it.

“Our goal is to work on defeating the current arguments against structural bonding,” he emphasizes. “It is a big hurdle, but necessary, not only for repair, but also for composite aircraft manufacturing.” Although the current state of the art for repairing composite primary structure is bolted repair, Beaumont says it is far from satisfactory. “As a developer of advanced composite structures, it hurts me to even think about drilling myriad holes through these very optimized and precisely designed and manufactured components.”

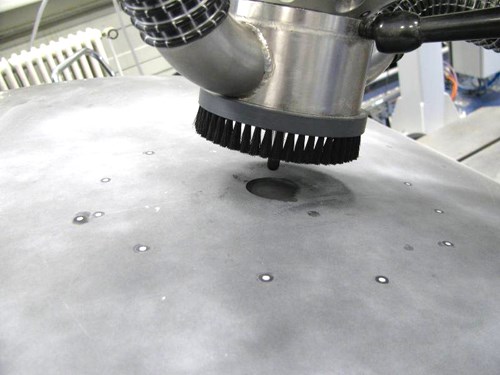

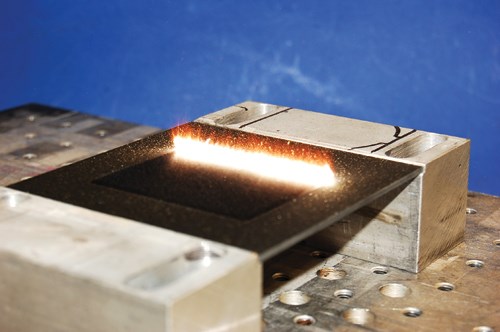

The envisioned final system is a fairly small mobile module that features a robotic arm with interchangeable heads that variously perform digital scanning, ultrasonic testing (UT), milling/grinding, automated tape laying and repair patch application. Suction cups would enable technicians to attach the module to the aircraft surface. An onboard data link would enable the technician’s necessary interaction with repair design personnel. The whole process could be done onsite in an aircraft hangar or even on the tarmac, Beaumont claims. “The ideal scenario is to roll the unit to the aircraft, position it, attach it, calibrate it, set up the data link and let it go.” The result would be repeatable and reliable quality, he predicts, “that is not dependent on the skill of an individual, using a hand sander or grinder, working to lines drawn on the laminate. A robot will be better than this case, seven days a week.”

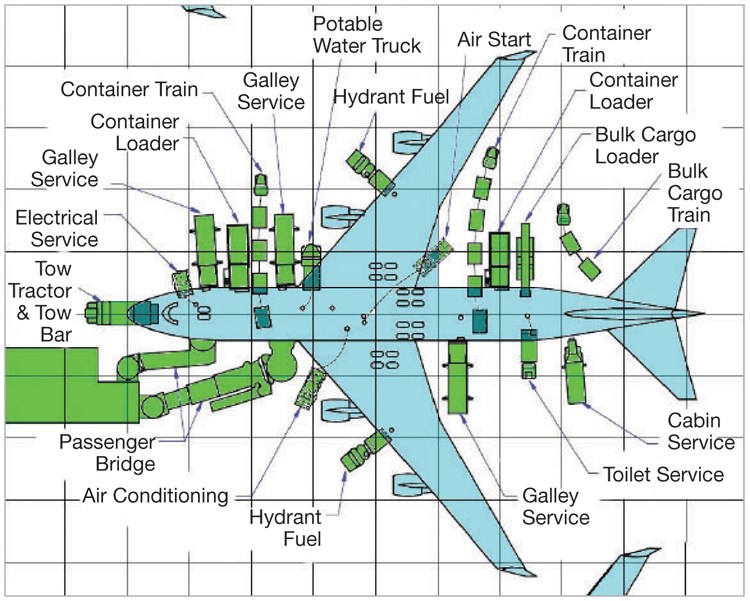

The development program’s three-year Phase I ended this year. Phase II begins in 2012. Partners include Eurocopter (Donauwörth, Germany); Cassidian Air Systems (Manching, Germany), which produces the Eurofighter; and Lufthansa Technik (Hamburg, Germany), a leading maintenance and repair organization (MRO). Blunt impact damage from ground vehicles, now under scrutiny by researchers employed by the U.S. Federal Aviation Admin. (FAA, Washington, D.C.), is “one of the main damage cases that we are looking at,” says Beaumont. “Although the location on the fuselage and the extent of damage will vary widely, it is a well-defined category of repair characterized by frequent occurrence and relatively easy access to the repair site.” He adds, “Thus, we are able to make the business case, especially once you include rotor blade repair and passenger cell repairs for Eurocopter plus specific types of damage to military aircraft, such as the Eurofighter.”

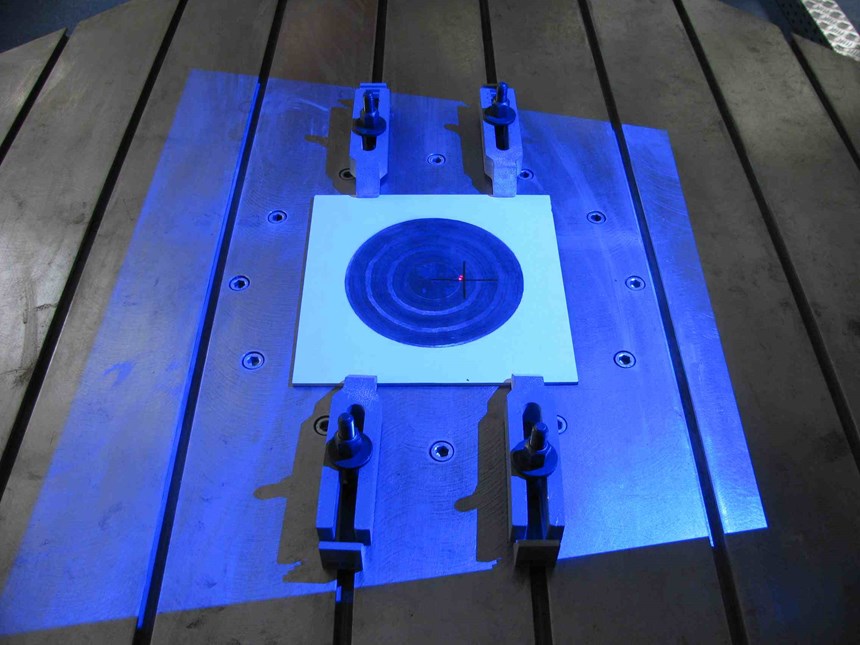

The proposed digital repair process begins with a stereoscopic camera that provides a very precise picture of the surface to be repaired and then digitizes it into a 3-D scan. The data provide an initial reference and will be used later to create a tool for layup and cure of the repair patch.

After initial 3-D scanning, the next step is phased array UT to determine the extent and degree of damage. This provides the data necessary to determine how much material must be removed and the precise parameters for designing the repair. Phased-array probes use multiple (typically from 16 to 256) transducers, each pulsed individually at separate times, allowing the sound wave to be shaped and steered so that multiple angles and focal depths can be examined within a fraction of a second. Results may be shown as A-scans, B-scans, C-scans or S-scans (typical of a medical ultrasound). This testing is used again as the final quality check to ensure there is no porosity in the repaired surface and that no further damage was done during the repair process.

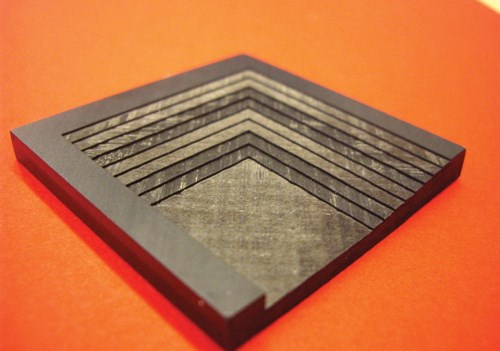

The results are sent to engineers in the design office, who respond with CNC directions for damage removal via robotic milling. Initial UT inspection results are analyzed by repair engineering personnel, who then respond with an appropriate repair design. The design then drives the digitally controlled creation of a precured composite repair patch. Beaumont explains that a hand-layed, wet layup patch that is cured on the surface being repaired is neither appropriate nor currently approved and certified for primary structures. “It is actually a fairly low-tech, quick and dirty approach, which works fine for nonstructural parts like fairings, but that does not reliably produce the type of high-quality, load-carrying, true composite primary structure repair that we require.” He adds, “A precured patch enables a much higher level of quality control.”

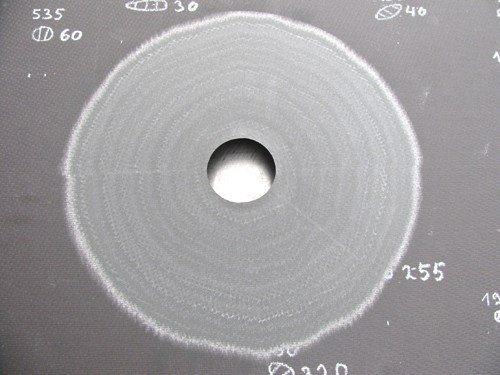

The digital scan is repeated and the results are compared to the original 3-D scan. A repair patch tool is created from this scan of the milled surface, followed by automated tape laying and cure of the actual repair patch. Finally, the precured patch is applied to the fuselage with film adhesive, and the bond is cured using a local vacuum bag.

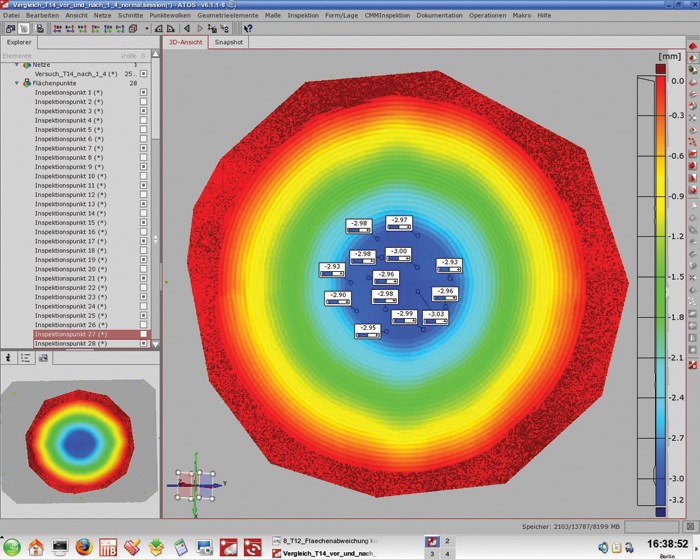

Beaumont notes that one of the keys to the EADS IW digital repair process is the ATOS high-resolution optical 3-D scanner, made by GOM mbH (Braunschweig, Germany). “It looks at the surface to be repaired and produces a very exact digital model of its shape both before and after grinding or milling away the damaged material.” The scans are vital to success, Beaumont contends, because “this is a very exacting process that we are trying to automate. It is not good enough to do robotic milling and assume the resulting surface is perfect, because when we create the repair patch, it needs to be made precisely for the scarfed surface.” The primary structures that will be repaired with this system are made to extremely tight tolerances. Even millimeters of difference between the patch and surface that needs repair are unacceptable because they would introduce deviation from the original structural design, resulting in a weakened bond due to inconsistent bondline thickness and degradation of the finished laminar surface. “Thus, the postmilling digital scan allows us to know exactly the difference [between] the milled surface and what we planned for in the repair patch design,” says Beaumont, “and then to compensate for that.”

Making sure the surfaces of the scarfed area and the precured patch match precisely is critical to obtaining a certifiable structural bond, but Beaumont’s team has found that surface contamination requires even greater vigilance. He explains that epoxy resins absorb not only moisture but also other contaminants, such as release agents and hydraulic fluids, which can migrate to the bondline. Beaumont asks, if the surface is well cleaned and prepped for bonding — via plasma treatment, for example — what will its condition be in five years? “This is one of the key areas,” says Beaumont, “How to understand that surface. What is dangerous over time? Can we really understand the state of the surface before bonding and then use that understanding to predict the long-term bond strength?” When asked if he is making headway, Beaumont responds, “Yes, but as my employees say all the time, ‘God created solids, the devil created interfaces.’ It is a large and complex subject.”

Phase I development has addressed each of the system’s building blocks. Team members are engaged in defining parameters for Phase II and will include sizing down each of these technologies to accommodate a user-friendly, mobile unit with a means to coordinate the exchange of functional heads on the robotic arm. For now, the process is designed only for thermosets, both carbon fiber and glass fiber-reinforced composites, the latter to address repair of Eurocopter rotor blades.

Automated alternatives

EADS IW’s process is not the only automated composite repair in development. Publicly released in 2005, the much-discussed Inspection and Repair Preparation Cell (IRPC) research began in 1999. An update was presented at the 2011 Commercial Technologies for Maintenance Activities (CTMA) Symposium (April 4-6 in Quantico, Va.), an annual meeting with about 200 attendees associated with maintenance and repair in the U.S. Department of Defense (DoD).

The current status of IRPC was summarized by project champion Frank Elliott of American GFM Corp. (AGFM, Chesapeake, Va., a member of the GFM machine tool organization headquartered in Steyr, Austria), Jani Le at Warner Robins Air Force Base (Warner Robins, Ga.) and program manager Bill Waddell of the National Center for Manufacturing Sciences (NCMS, Ann Arbor, Mich.). Automated functions include creation of 3-D surface models, damage inspection and evaluation, damage removal, preparation of repair materials, and verification of the completed repair. However, application and cure of the repair patch and core plug — the demonstration case was the C-130 radome — would remain a manual operation.

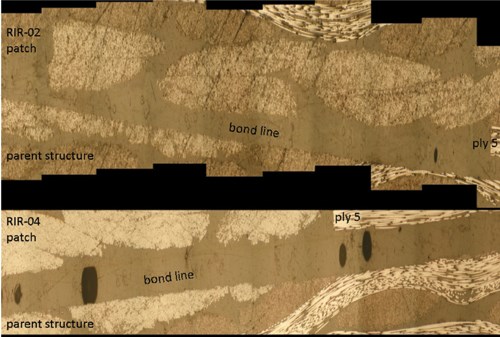

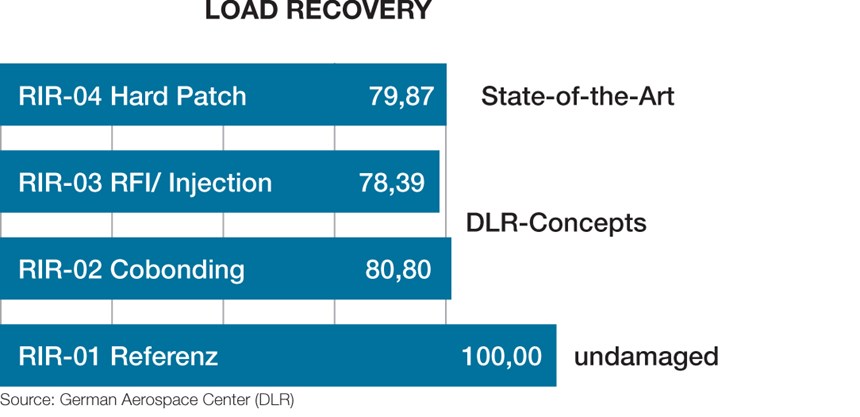

Elsewhere, the German Aerospace Center (DLR, Stuttgart, Germany) is exploring automated composite repair as well, using a resin infusion-based system similar in many respects to the EADS IW system. The stated goal for each is certifiable bonded repairs to carbon composite primary structures. Both methods employ 3-D laser scanning of surface geometry; integrate with CATIA CAD software (Dassault Systèmes, Vélizy-Villacoublay, Cedex, France) to develop scarf design; and employ computer-controlled milling for damage removal. However, the DLR process also eliminates fabrication of tooling and a precured repair patch by using resin infusion to impregnate in situ a dry patch preform. DLR claims its method drastically reduces process complexity for curved parts and yields a patch with mechanical performance equal to that of state-of-the-art precured, or hard, patches. Microscopic evaluation reportedly showed a good bondline with no voids for infusion repair but identified voids in the hard patch. Tensile test results for both repair types were basically the same, achieving 80 percent total load recovery. Future developments will include miniaturization and improved mobility of machining as well as simulation and optimization of 3-D patch repairs.

Seeking a better bond

Because the bondline between a patch and a repaired surface is so important, efforts are underway to optimize surface preparation. For example, cleanLASER (Herzogenrath, Germany) claims it has developed a laser surface pretreatment for carbon fiber composites that enables superior structural bonded repairs, without the use of chemicals and abrasives and with no waste. An adapted laser and optical machining system were evaluated on real parts and were designed to be portable and mountable onto aircraft surfaces even in the field, enabling fully automated composite repairs with greater quality and reliability. The company claims that ply-by-ply damage removal is possible and that the laser achieves surface energy activation that increases bond joint strength by up to 20 percent. The company also is participating in the European Commission Seventh Framework Programme (7th FWP) Eureka project titled “Portable LAser system for the SurfacE preparation of composite Repairs,” or PLASER. This three-year, €1.3 million (nearly $1.8 million) program started in 2009. Its aim is the development of a portable, laser-based repair unit for damaged aerospace composite parts, using novel automated and certified material removal technology plus cutting of fiber plies with one tool. Targeted benefits include greater accuracy, reduced repair time and, most importantly, elimination of human error. Partners include Laser Zentrum Hannover (LZH, Hannover, Germany) and an aircraft repair technology company GMI Aero (Paris, France).

IAPETUS is another 7th FWP project valued at €3.5 million ($4.75 million) over three years, ending in June 2012. Its mission is to address problems with adhesively bonded repairs to composite primary aircraft structures by developing simplified on-aircraft curing technologies with integrated cure monitoring and damage sensing, using carbon nanotubes (CNTs). The technical goals will be demonstrated at coupon and component levels. Results to date include improved peel strength from lab-scale resistance heating of patches vs. conventional cure; deployed cure monitoring of the repair patch via thin film dielectric sensors enhanced with CNT materials; and initial trials of damage detection in smart repair patches. The IAPETUS consortium, led by Tecnalia (San Sebastián, Spain), brings together three European universities; three aircraft and component manufacturers (Daher in Saint-Julien-de-Chedon, France; Helenic Aerospace Industry in Athens, Greece; and PZL in Warsaw, Poland); and supplier Huntsman Advanced Materials (Basel, Switzerland).

Induction Heating and Health Monitoring Solutions for Smart Aircraft Maintenance using Adapted Composite Patches (INDUCER) is another notable smart patch project, also funded under the 7th FWP. It began in January 2010 and ended in June 2011. Pursued by GMI Aero and TWI (formerly The Welding Institute, Cambridge, U.K.), INDUCER seeks to enable high-integrity bonded repairs using a magnetostrictive sensor mesh embedded in the repair area. The mesh comprises small-diameter sensors that measure changes in magnetic properties due to stress and is said to perform multiple functions. It enables Smart Curing of the bond by replacing conventional conduction heating (via heating blankets) with induction heating. It also provides the means to monitor the structural integrity of the repair in service, and it doubles as the lightning protection and grounding element in the repair area. Structural monitoring is accomplished by interrogating the magnetostrictive sensors at regular maintenance intervals to acquire strain field data changes. The program output will include repair equipment, software and sensors.

Repair technician certification

Abaris Training’s Hoke is familiar with the issues of certifying composite repair technicians. His company at one time provided training for Ottawa, Ontario-based Transport Canada’s (the Canadian equivalent of the FAA) certified repair technician program. Hoke also has been a member of the Training Task Group within the Commercial Aircraft Composite Repair Committee (CACRC) for more than 20 years. CACRC comprises the Air Transport Association of America Inc. (ATA, Washington, D.C.) and the International Air Transport Assn. (IATA, Montreal, Quebec) as well as most international aircraft OEMs and airlines. Its standards-setting activities are overseen by SAE International (Warrendale, Pa.). Hoke believes that a path could be emerging, after many years, for this type of certification through SAE’s Performance Review Institute (PRI), which helps to advance mobility-related industries through development of performance standards and administration of quality assurance, accreditation and certification programs. Nadcap (Warrendale, Pa.) is the global cooperative program that PRI administers in an effort to improve quality assurance in the aerospace industry, working with companies to audit and certify that they meet specific industry standards. The benefits of a Nadcap audit include verification that a company builds/repairs to a given industry standard. It releases the company from the otherwise necessary repeat audits for each customer. PRI conducted more than 4,000 Nadcap audits in 2010, 200 of which were done for companies that build composite parts.

Although PRI has not yet audited training organizations, Hoke believes it is feasible. A graduate of a certified composite repair training program would take a written test at the certified school and then perform a practical repair exercise. The repaired structure would be shipped to an independent test lab for both NDI and destructive testing to verify the repair bond’s strength. In one proposed scheme, written and practical exam results would be passed to PRI for review and, assuming the results met the developed standards, a composite repair technician certification would be issued. The standards could be written by the SAE’s CACRC Training Task Group. Because it lacks the funding and personnel to support a mandate, the FAA would probably publish an Advisory Circular recommending, rather than requiring, that airlines and MROs internally require Level 3 or Level 4 composite repair certification for technicians who perform structural composite repairs to aircraft such as the Boeing 787 or Airbus A350. This would put composite repairs on par with welding and NDI technicians for certain airframes and components. However, current composite repair technicians would have to be grandfathered to make this system practical for airlines and MROs by avoiding the operational disruptions that would accompany an effort to certify already active crews.

In what could be a first step toward this eventual goal, the FAA issued a draft Advisory Circular AC 65-CT this past spring, concerning the development of training qualifications for composite maintenance technicians at airlines and MROs, recommending that each MRO develop its training program and then have it approved by the FAA. Public comment ended in March of this year, and a revised circular was issued on Aug. 3 as AC 65-33 “Development of Training/Qualification Programs for Composite Maintenance Technicians.”

Meanwhile, PRI has begun a survey of the aircraft repair industry to better gauge interest in the development of a standards and qualification framework.

Looking forward

In its description of Project P3.1 for “Robust, repeatable, reliable repair processes,” CRC-ACS, a Victoria, Australia-based composites research coalition of 28 international organizations, aptly summarizes the current status of structural bonded repair on commercial aircraft: “As new aircraft programs drive the use of composites into safety-critical primary structure, the design and certification of repairs becomes evermore challenging.” As manufacturers of passenger aircraft increasingly turn to highly optimized and complex composite structures, the resulting repair challenges could soon bring about use of automated robotic repairs freed from human variability. In the meantime, development of new repair technologies continues at an accelerated pace as the aerospace industry seeks to elevate bonded repair process control to the level required to ensure aircraft safety and reap the benefits of lower lifetime maintenance costs promised by today’s all-composite airframes.

Related Content

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreRead Next

The craft of aircraft repair

As the use of composites on commercial and military aircraft grows, repair facilities seek more science in what remains a primarily manual art.

Read MoreUpdate: Automated repair cell

Consortium makes progress on aircraft component diagnostics/repair cell concept.

Read More