Statistical data pooling in design allowables

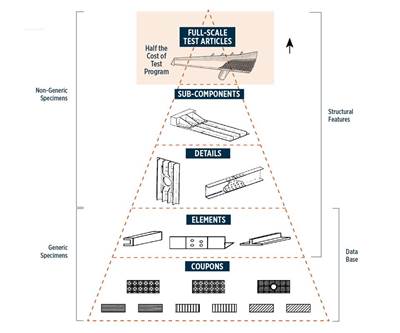

In the debate about virtual testing’s role in the design allowables process, one common ground is that it can reduce the number of physical tests required in the traditional building block approach (BBA), in the same that way that data pooling is already used.

Share

Read Next

In the debate about virtual testing’s role in the design allowables process, one common ground is that it can reduce the number of physical tests required in the traditional building block approach (BBA), in the same that way that data pooling is already used. Lockheed Martin Aeronautics (Fort Worth, TX, US) senior staff engineer Dr. Carl Rousseau presented a paper illustrating the use of data pooling at CAMX 2015 titled, “Case study: Accelerated insertion of a new material into production use.”

Though this was a fairly special case — a unidirectional carbon fiber/epoxy tape that had been used by a sister business unit, but was new to the Fort Worth site — it demonstrated the cost and time reduction possible mainly by cutting the number of test coupons required. Compared to the allowables development norm of 24 months, $1.5 million and 3,000 coupons, this project was completed in 16 months, required $350,000 and only 820 coupons.

Rousseau sets some ground rules for data pooling, “You have to watch variability — if you get more variability due to hot/wet performance, you cannot pool that data. And the failure mode has to be the same.” He gives an example: “Un-notched compression (UNC) and open-hole compression (OHC) test coupons all have 0° fibers failing in compression, so they all share the same failure mode. Thus, we don’t need 18 of each, simply 18 in total.” However, interlaminar shear (ILS) and interlaminar tension (ILT) do not share the same failure mode. “For ILT, you are only doing one test for that failure mode, so you’re stuck doing all of the coupons in order to get an acceptable statistical spread,” Rousseau explains.

The National Center for Advanced Materials Performance (NCAMP) works with the FAA and industry partners to qualify material systems and populate a shared materials database that can be viewed publicly. NCAMP started as an FAA-funded program within the National Institute for Aviation Research (NIAR) at Wichita State University (Wichita, KS, US) and stemmed from NASA's 1995 Advanced General Aviation Transport Experiment (AGATE). Rousseau says NCAMP pools composite test data across environments (e.g., room temperature ambient, cold temperature ambient, hot/wet), but not across laminates. He proposes both, explaining that laminates for most structural parts only have (0°/90°/+45°/-45°) fiber orientations, but manufacturers will test the full range of “hard” laminates (more 0° plies) to “soft” laminates (more 45° plies) to cover all the various parts that might be designed.

Rousseau sees NCAMP-type industry-shared databases as another tool to help reduce allowables tests. He refers to a project being developed by Materials Sciences Corporation (MSC, Horsham, PA, US). “We have 30 years of data on all of these CF/epoxy laminates that are relatively similar, so it is possible to develop an upper and lower bound for material property values. For example, interlaminar shear strength (ILSS) is between 6 and 12 ksi. So maybe I can find a relationship based on historical data. Or I could use simulation here to reduce the total coupons needed.” Rousseau says this work is proceeding through a Small Business Innovation Research (SBIR) grant with the Air Force Research Laboratory (AFRP, Dayton, OH, US).

But will this approach really help? Rousseau hopes so, “Right now, we’re gathering military data that can be shared with other defense contractors, including rotorcraft defense contractors. MSC has a web-based tool that allows you to cross-plot all of this data, but there are still data rights and ITAR issues.” He says there is interest to make this a publicly available tool, adding “That’s really what Mil-Handbook-5 for metals (now called MMPDS) is, and CMH-17 has a similar set of publicly available data including NCAMP. We are all thinking in the same way.” He notes that each company is going to want its own data behind its own firewall for security, “but that’s just a software architecture issue. It doesn’t invalidate this approach.”

Read Next

Accelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)