Vectorply Corporation Introduces Heaviest VectorUltra Product

Vectorply Corporation is pleased to introduce the latest product addition to the VectorUltra line of advanced composite reinforcements. The 94 oz/yd² carbon quadraxial fabric, named C-4QX 9400, is an all-standard modulus carbon fiber quasi-isotropic reinforcement fabric that is excellent fit for tooling, panel, and thick section advanced composite applications.

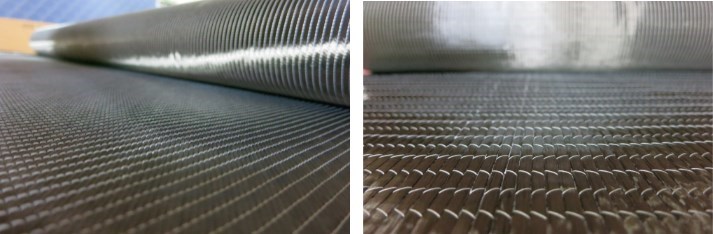

Pictured are two of the substrate layers for Vectorply’s C-4QX 9400. On the left is C-BX 2400, and on the right is C-LT 2200.

Vectorply’s C-4QX 9400 is constructed utilizing a balanced and symmetric construction (mirror image), [90°/0°/45°/-45°]S stacking sequence of approximately 400gsm carbon plies. The architecture of the fabric provides a very low and consistent coefficient of thermal expansion (CTE) and an un-coupled (non-potato-chipping) laminate, an ideal combination for high-performance composite tooling which experience large temperature changes.

The symmetric construction allows panel manufacturers to fabricate ultra-flat panels, and the 3200gsm areal weight allows for minimal labor requirements for building thick cross sections. In addition, the quasi-isotropic nature also provides high bearing strength, which combined with its high areal weight, is a perfect material for inserts and hard points requiring mechanical fasteners.

The C-4QX 9400 fabric is a versatile option for manufacturers since it can be used in both prepreg and resin infusion applications. It is also available in a “tapered” option along the fabric width, allowing for scarf joining and consistent thickness across joints.

For more information on the heaviest symmetric construction (mirror image) quadraxial standard product readily and commercially available in the market, visit Vectroply.