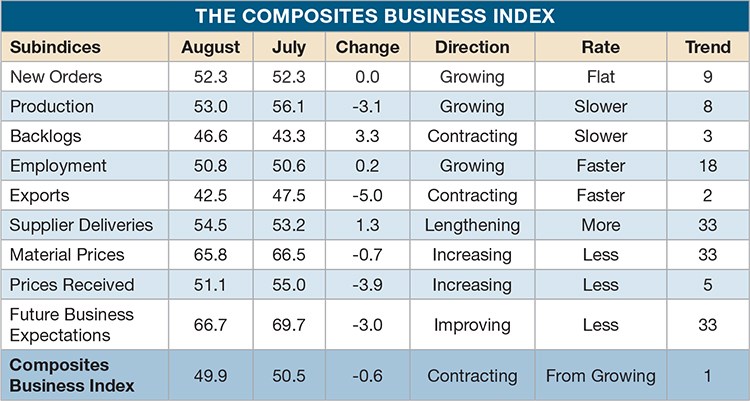

Composites Business Index 49.9: Industry virtually flat

Steve Kline, the director of market intelligence for Gardner Business Media Inc. (Cincinnati, Ohio), plots the Composites Business Index for July and August 2014.

In July, the Composites Business Index (CBI) 50.5, indicated growth in nine of the preceding 10 months. The Index was 5.9 percent higher than in July 2013 — the 11th consecutive month that growth was greater than one year earlier. The annual rate of change had accelerated for six straight months.

New orders increased for the eighth month in a row, but it was the slowest increase since November 2013. Despite running high in 2014, production continued a downtrend begun in April. Having contracted in three of the previous four months, backlogs increased at their slowest rate since August 2013, yet was still higher than one year earlier in each of the previous 11 months — a positive sign for capacity utilization and capital equipment investment. Employment continued to grow, but at its lowest level since June 2013. After expanding in June, exports contracted again in July. Supplier deliveries continued to lengthen, but the rate had slowed since March.

In June and July, material prices increased at their fastest rate since early 2013. Fortunately, prices received had accelerated upward since March and were at their highest level since June 2012. Future business expectations were above the historical average, but had fallen since February and were at their lowest since late 2013.

Facilities with more than 250 employees had grown since November 2013, but the rate in July was the lowest since December 2013. Facilities with 20 to 49 employees experienced a similar decline. Fabricators with 50 to 249 employees grew at a rate similar to June. Those with fewer than 20 employees contracted significantly after growing for two months.

Regionally, the North Central – West grew fastest, despite contracting in two of the previous three months. The West grew at its second slowest rate of 2014. The Northeast and North Central – East contracted slightly after seven and nine months of growth, respectively. The Southeast’s contraction accelerated for a second month.

Future capital spending plans fell to their lowest level since November 2012 — 35.7 percent less than they were one year ago.

In August, the CBI of 49.9 indicated the industry was essentially flat, breaking a string of 10 consecutive months of growth. Nonetheless, the Index was higher than it was one year earlier. In fact, the month-over-month rate of change had grown since September 2013, and the annual rate of change had accelerated for seven months.

There were some subindex positives. New orders increased for the ninth month in a row. Production expanded for the eighth straight month (but its index fell to its lowest level in 2014). Backlogs, however, contracted for the third month in a row, but more slowly. Compared to one year ago, the backlog index was 17.4 percent higher this August and had shown an accelerated growth rate every month in 2014 — a strong sign that capacity utilization and capital equipment investment will increase through 2015. Employment grew but at its slowest rate since June 2013. Exports had contracted sharply for two months, reaching their lowest level since the index began (December 2011). Supplier deliveries continued to lengthen at a moderately increasing rate, a trend since October 2013.

Material prices continued to increase, near peak levels reached since the beginning of 2012. Prices received had increased for five straight months — their longest sustained stretch of increases since summer 2012. Future business expectations was at its lowest level since September 2013.

Mid-sized facilities (20 to 249 employees) continued to expand. Those with less than 20 employees had contracted four of the previous six months. Facilities with 250 or more employees contracted for the first time since October 2013.

Regionally, the West and Northeast expanded in August. The North Central – West contracted after expanding in July. Both the North Central – East and the Southeast had contracted for two straight months.

Future capital spending plans had contracted significantly the previous two months. The annual rate of growth slid to its second slowest rate since November 2013.

Read Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)