Composites Business Index 54.1: Best since May 2012

Gardner Business Media’s director of market intelligence Steve Kline, Jr. updates the turn-of-the-year Composites Business Index for the months of December 2013 and January 2014.

Share

Read Next

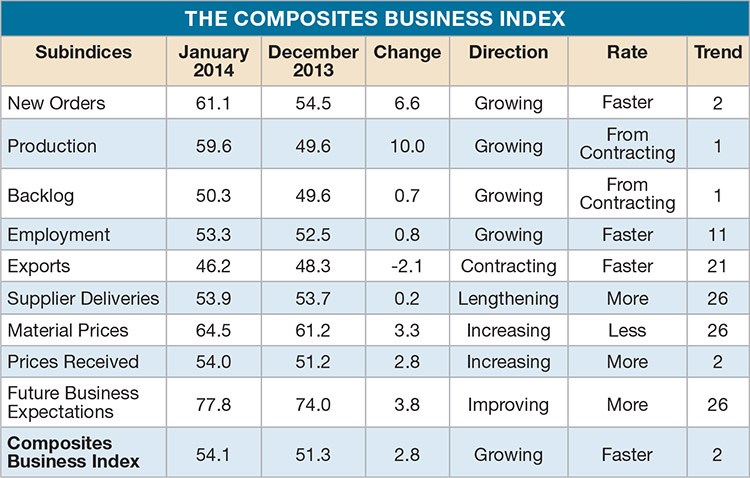

The December 2013 Composites Business Index, 51.3, showed that U.S. composites business activity ended the year on an upswing. In fact, conditions had improved generally since July 2013 — December’s CBI was 18.8 percent higher than in December 2012.

New orders grew at a significant rate for the second time in three months. However, production contracted at a modest rate for the second straight month. As a result, the backlogs index had improved dramatically since August 2013, indicating that fabricators’ capacity utilization would improve in 2014. Employment had grown at an increasing rate since June 2013. Exports continued to contract but the rate had slowed steadily since December 2012. Supplier deliveries continued to lengthen at a relatively constant rate.

Material prices were increasing, but the rate had slowed since early in 2013. Prices received increased but the rate was much slower than that of the increase in material prices. Future business expectations reaching their highest level since March 2012.

Facilities with 50+ employees expanded as they had for most of 2013. Those with less than 49 employees contracted in December, but the rate of contraction at plants with 19 or less employees was slower then in the previous three months.

The Pacific region grew, and at a faster rate than each of the previous three months. The West South Central grew at the second fastest rate. The East North Central also grew. The Mountain region was flat. All others contracted.

Future capital spending plans were at their third highest level since February 2013. Spending plans were 32.2 percent higher than in December 2012 and the annual rate of change was faster than in November, indicating that capital spending could go up significantly in 2014.

As the New Year turned, January’s CBI of 54.1 showed U.S. growth at its fastest rate since May 2012, accelerating since July 2013. The CBI was 8.6 percent higher than it was in January 2013 and it was the fifth straight month that it was higher than in the same month of the previous year.

New orders shot up, reaching their highest level since February 2012. After two months of very moderate contraction, production jumped to its fastest growth rate since April 2012. Backlogs grew for the first time since May 2012, indicating that the industry should see better capacity utilization in 2014. Employment grew, and had done so at a steadily increasing rate since June 2013. Exports remained mired in contraction at a rate similar to that in 2013. Supplier deliveries continued to lengthen, at a slightly faster rate than in the second half of 2013.

Material prices grew at a faster rate, continuing a trend begun in August 2013. Prices received had grown faster each of the previous two months, and at their fastest rate since January 2013. But the rate was much slower than that of material prices. Future business expectations had soared since September 2013, reaching their second highest level since the CBI was first recorded in December 2011.

For the first time since March 2013, facilities of all sizes grew in January. Fabricators with 50+ employees remained strong. But the improvement in the overall index was driven by smaller facilities. Fabricators with 20 to 49 employees expanded for the second time in three months, at the fastest rate since June 2012. Those with fewer than 20 employees grew for the first time since March 2013.

New England grew fastest, followed by the West North Central, which grew for the first time since July 2013. The Middle Atlantic expanded after two months of contraction. The East North Central grew for the third time in four months. The Pacific region, which grew the fastest in December 2013, expanded for the fourth straight month. The Middle and South Atlantic regions continued to contract.

Future capital spending plans were 17.8 percent higher than they were a year ago. It was the fifth straight month that they were higher than one year earlier.

Read Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)