Composites Business Index 54.5: Growth remains strong

Steve Kline is the director of market intelligence for Gardner Business Media Inc. (Cincinnati, Ohio), the parent company and publisher of Composites Technology magazine. He started as a writing editor for another of the company’s magazines before moving into his current role. Kline holds a BS in civil engineering from Vanderbilt University and an MBA from the University of Cincinnati.

The U.S. Composites Business Index for May, 56.8, saw every subindex contribute to a faster growth rate. New orders jumped dramatically, reaching their third highest level since the CBI began in December 2011. Production continued to expand significantly. Backlogs expanded at their fastest rate since March 2012 — 18.5 percent higher than one year earlier. The accelerating annual rate of change in backlogs indicated higher capacity utilization and capital spending for the remainder of 2014. Employment expanded at its second fastest rate since the Index began. Exports contracted for the second straight month. Supplier deliveries continued to lengthen at a slightly faster rate.

Material prices increased at their fastest rate since February 2013. Prices received increased as they had done in five of the previous six months. Future business expectations improved and remained at a historically high level.

Most fabricators saw improved business conditions. Most dramatically, shops with 19 or fewer employees, after contracting for two months, saw their index soar to 58.6 — their fastest growth since the Index began. After contracting in April, midsize facilities (50 to 99 employees) expanded slightly in May. Facilities with more than 250 employees grew at their second fastest rate since July 2012.

Regionally, the West grew at the fastest rate of any region since the Index began. It was followed by the Northeast, which has grown for six straight months. The North Central – East region had grown at a consistently strong rate for three months. The Southeast and North Central – West continued to expand.

In May, future capital spending plans had been above $1 million six of the past seven months. Compared to one year ago, spending plans were up 14.9 percent, while the annual rate of change had grown at a relatively constant rate the previous four months.

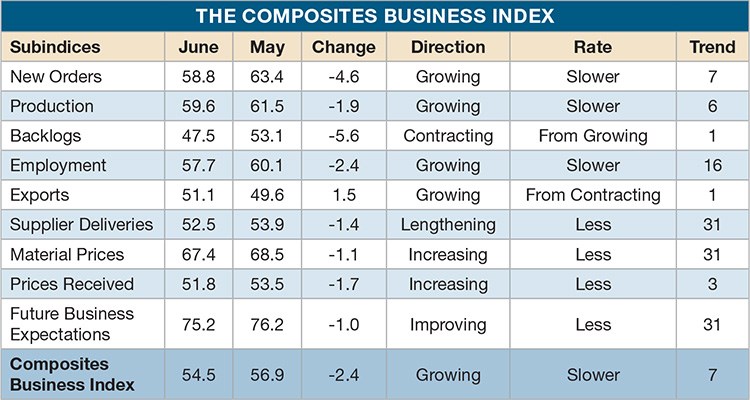

June’s CBI of 54.5 showed growth for the seventh straight month. Although the rate decelerated compared to May, June still saw the third fastest growth since May 2012. Compared to one year earlier, the CBI was up 12.1 percent. May was the ninth consecutive month the Index had increased compared to one year earlier, and the second month in a row of more than 10 percent month-over-month growth. The annual rate of change had grown at an accelerating rate for five months in a row.

In June, every subindex but exports contributed to the slower growth rate. For the seventh month in a row, new orders expanded, continuing a trend begun in August 2013. Production showed strong growth for the sixth straight month. Backlogs contracted for the second time in three months but were still 7.7 percent higher than they were a year earlier. The annual rate of change in backlogs continued to accelerate, indicating higher capacity utilization and capital spending through 2014. Employment continued its 2014 expansion at a rapidly accelerating rate. Exports increased for the second time in 2014. Supplier deliveries continued to lengthen at a steady rate.

Material prices increased at a slightly slower rate in June, but the rate was still among the fastest since February 2013. Prices received increased for the third straight month. Future business expectations dipped from the peak level attained in February.

All fabricator groups expanded or the first time since February. The growth rate remained strong at facilities with more than 250 employees (>60.0 for three of the previous four months). There was significant improvement at plants with 50 to 249 employees, but growth slowed dramatically for those with fewer than 50 employees.

Regionally, the West grew fastest (>65.0) for a second straight month. The North Central – East followed, above 56.0 for four straight months. The Northeast also posted growth, but the Southeast and North Central – West contracted after expanding in May.

Future capital spending plans reached their second highest level since July 2013. Compared to a year earlier, June’s spending plans were up 30 percent. The annual rate of change returned to double-digit growth for the first time since January.

Read Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.JPG;width=70;height=70;mode=crop)