CW Business Index at 48.6 – US industry contraction accelerates

Steve Kline, Jr., the director of market intelligence for Gardner Business Media Inc. (Cincinnati, OH, US), surveys the CompositesWorld Business Index for May 2015.

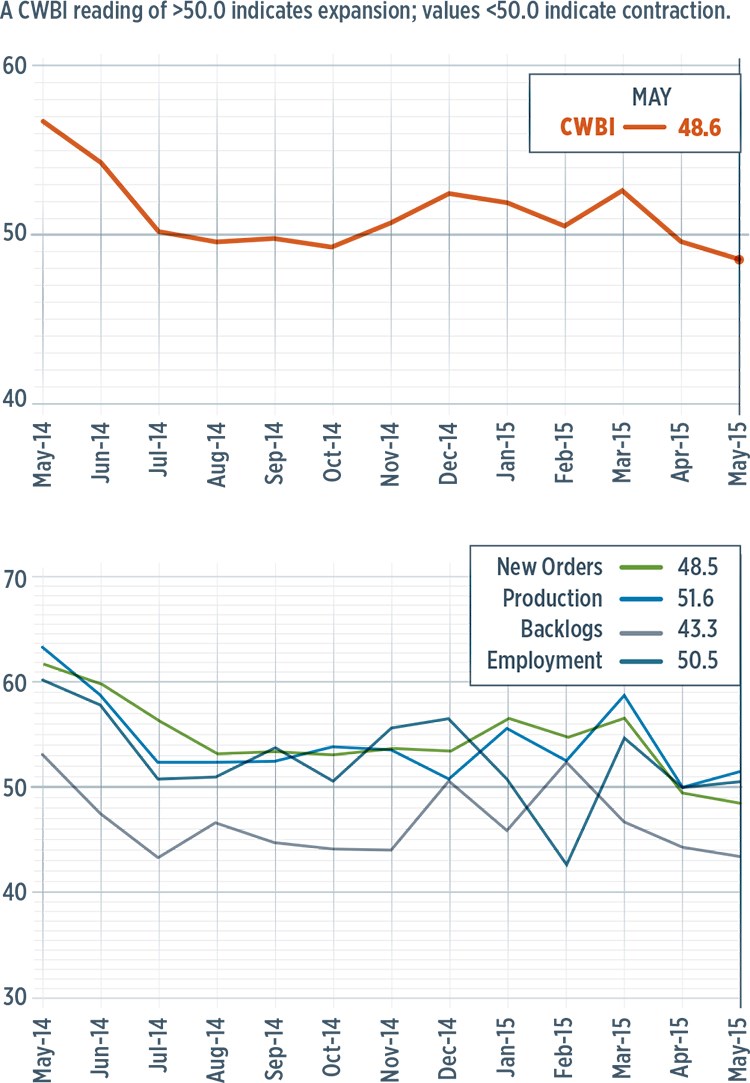

In May 2015, the CompositesWorld Business Index showed an overall reading of 48.6, indicating that the US composites industry contracted for a second month in a row and that the rate of contraction had increased compared with April. The Index was at its lowest level in May since August 2013. Compared with one year earlier, it contracted 14.6%, which was the fastest rate of contraction since December 2012. On an annual basis, the industry contracted in May for the first time since January 2014.

New orders in May contracted for the second month in a row. This ended a US trend of steadily accelerating growth in new orders that had begun back in July 2014. Production increased in May after being flat in April. Generally, production had been stronger than new orders, which had led to contraction in backlogs. Other than in December 2014, the backlog subindex had hovered around 44. Compared with one year earlier, backlogs had performed quite poorly in the five months preceding June 1. The annual rate of change in backlogs had contracted faster in the two preceding months. The trend to that point indicated that capacity utilization in the industry would see slower growth or might contract during the remainder of 2015. Employment in the US composites industry was virtually unchanged in May. Exports had contracted since July 2014. Supplier deliveries lengthened again in May, at about the same rate as they had since January 2014.

In April and May, material prices increased at a faster rate than they had the previous four months. However, material price increases had been much more subdued over that same six-month period than at any other time since the fourth quarter of 2012. Prices received decreased for the first time since October 2014. The US composites industry’s future business expectations subindex had been bouncing up and down quite a bit since the summer of 2014, but in May, that subindex was at its lowest level since October 2014 but also was right at its historical average.

All but the largest US composites fabricators contracted in May. Companies with more than 250 employees showed significant improvement in their May subindex, increasing to 55.5 from 45.8. Facilities with 100-249 employees moved in the opposite direction as their subindex dropped to 49.1 from 64.2. Fabricators with 20-99 employees contracted for the second month in a row. By the end of May, fabricators with fewer than 20 employees had contracted every month but one since June 2014.

The North Central – East was the fastest growing region in May. It had expanded in May for five of the preceding six months. The only other region to grow was the North Central – West, which had done so in six of the previous eight months. The West, which was the fastest-growing region in April, saw its subindex drop to 47.7 from 57.4. The Northeast contracted significantly in April and May and in five of the preceding six months.

Future capital spending plans had been below average in March and April and were, again, in May. Compared with one year earlier, they had contracted more than 20% in each of those months. The annual rate of change had contracted at an accelerating rate during that period. Spending plans in the US composites industry were contracting, in May, at an annual rate of 14.1%.

Read Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)