Programming

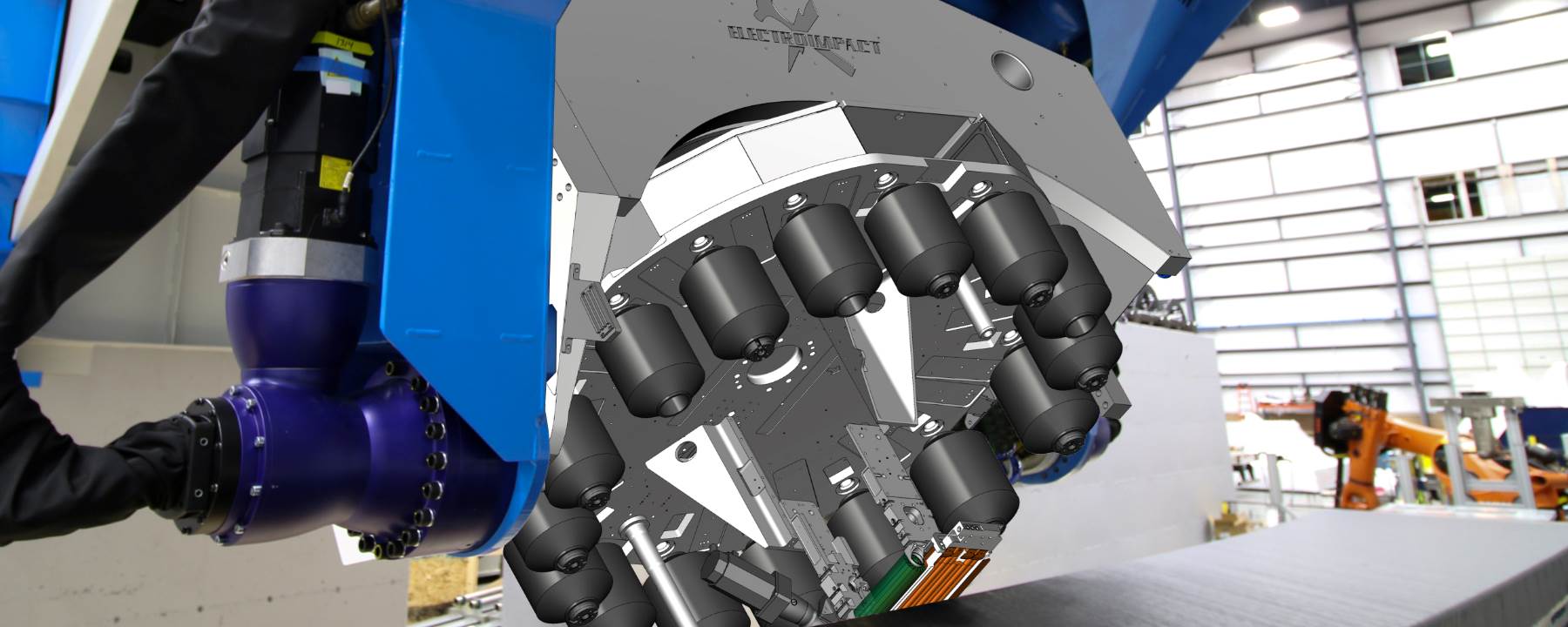

Tool paths are the foundation of automated composites manufacturing. Sound machine paths minimize process errors, ensure layup quality and don’t cause collisions. CGTech is an expert at generating tool paths for a variety of composites processes including AFP, ATL, Probing, Cutting, Stitching, NDI and Quality processes. Close partnerships with a myriad of machine vendors allows CGTech to create the same machine code that will run on your hardware.

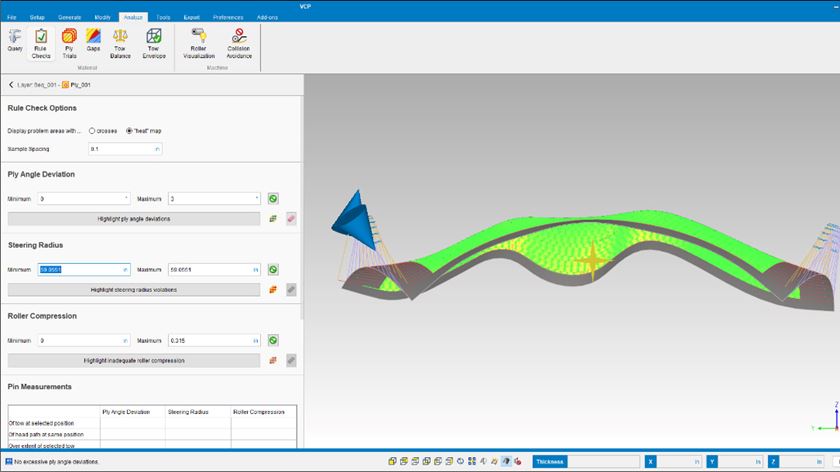

Programmed tool paths for AFP and ATL can vary depending on process and manufacturing allowables. CGTech’s composite programming software, VERICUT Composite Programming (VCP), allows users to tailor their headpaths to best suit their specific process. For example, material attributes such as width and steerability, both of which have a high degree of impact on the quality of the final part, can be directly controlled within VCP. The method that the material is draped over the tool’s surfaces, whether it should strictly adhere to the ply angle or be allowed to deviate slightly – and by how much – is also directly controlled by the user. By enabling programmers with a robust set of tools, machine paths are created that best suit the user’s needs.

Once generated, tool paths can be analyzed for multiple aspects of producibility such as how far off the paths are from the desired ply angle, if the material is under tension or compression due to forced changes in direction (called “steering”) and identification of areas where complete material compaction is not present. Analyzing producibility at this stage facilitates a straightforward process in headpath modification that reduces process failures and part defects during manufacturing.

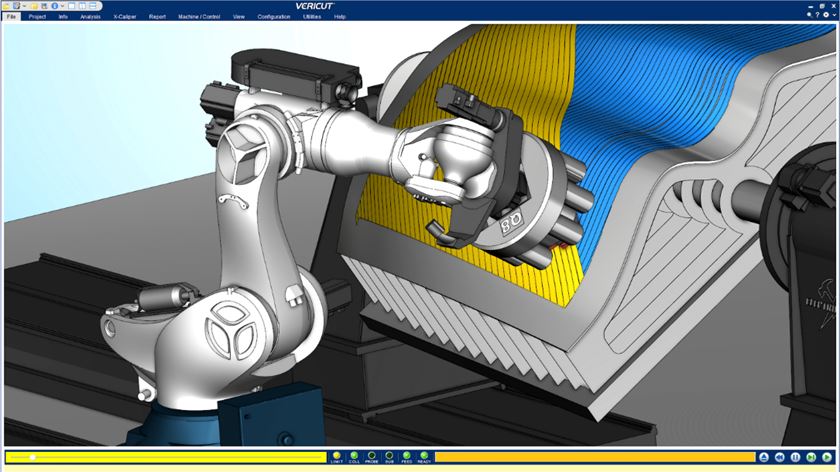

Once finalized, headpaths, which are comprised of machine-independent data until this point, are converted (“post-processed”) into machine-specific data via a machine-specific post-processor. These post-processors are tailor-made for each customer and their machine’s unique configuration and capabilities. Final checks can be performed to verify and eliminate potential collisions between the tool surface and the end of the machine.

In addition to generating the main processes toolpaths, paths for supporting processes can be generated together with the primary AFP and ATL processes. Whether the user needs to cut along the manufacturing-defined edge of part, probe the location of the tool, or label parts with an automated printer, VCP can generate paths and associated G-code to facilitate these processes.