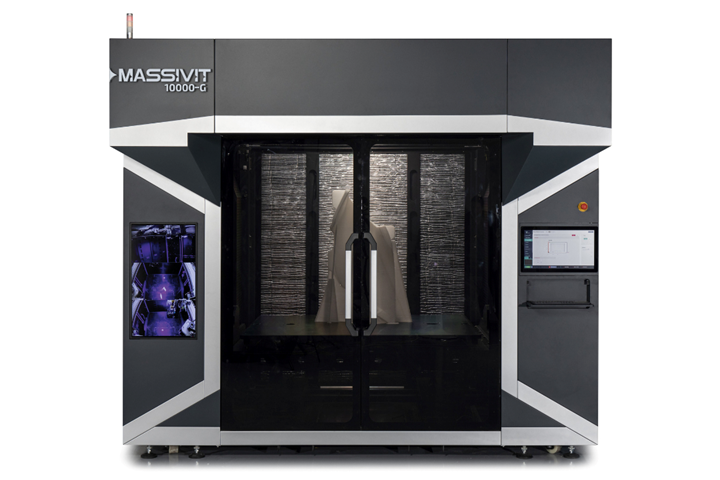

Large-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

Share

Massivit 3D (Lod, Israel) is transforming additive manufacturing with its patented gel dispensed printing (GDP) dual-head systems, which the company says are significantly faster than other 3D printing technologies. The high-speed system is applied to print full-sized parts (4' × 5' × 6') across the entire manufacturing line. Industrial, isotropic, epoxy-based molds with high-performance materials are made possible in a matter of days instead of weeks or months.

Founded in 2013, Massivit’s vision is to transform the manufacturing of large parts from traditional processes to on-site, ultra-fast, digital and sustainable fabrication using industrial-grade materials. Driven by a passion to solve real-world manufacturing needs, Massivit has developed a portfolio of large-scale 3D printers, enabling customers across 40 countries to automate their production, reduce manufacturing costs and minimize waste.

Its latest printer, the Massivit 10000-G is the culmination of this vision. The system crafts epoxy molds, but also enables tooling applications for thermoforming, resin transfer molding (RTM) and reaction injection molding (RIM). New features expand this output to include direct custom manufacturing of end-use parts and functional prototyping. Custom molds for composite parts can be manufactured using Massivit’s patented cast-in-motion (CIM) technology to automate isotropic mold production and decrease fiber-reinforced polymer (FRP) tooling time by up to 80%, thereby decreasing labor-associated costs by 90%.

Massivit says its systems also make it easy to stay green, with sustainable, efficient, digital printing. Users only need to use the core material required, waste associated with CNC machining is eliminated and the need for extensive support structures is removed.

Related Content

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Sumika, Hexagon digitize sustainable compounds, enable 60% carbon reduction for new vehicles

Digitized mechanical and environmental performance of recycled short glass fiber-reinforced PP compounds supports the transition to more sustainable vehicles.