Digitization in CW Articles, News and Products

CW's Latest Digitization Articles

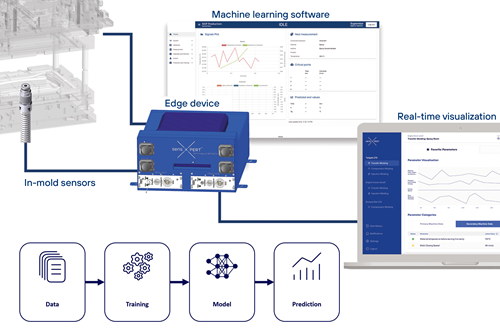

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Ginger Gardiner | CompositesWorldUsing a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

3D-printed CFRP tools for serial production of composite landing flaps

Ginger Gardiner | CompositesWorldGKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

Ginger Gardiner | CompositesWorldThe historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Digitization in the news

European SUSPENS project targets green composites production

The 13-partner program will addresses the challenge of reducing the environmental footprint of sandwich and hollow composite structures via bio-sourced resins and carbon fiber precursors.

Dieffenbacher TailoredPress promotes 70% energy savings

Variable-speed pump drives minimize unnecessary energy consumption during metal and composites forming operations.

Digitization products

Digital mold solution improves energy savings, reduces cycle times

Jessica PompiliCAMX 2024: SensXPERT showcases the Digital Mold, integrating material characterization sensors directly into plastics and composites manufacturing processes for improved product quality and scrap reduction.

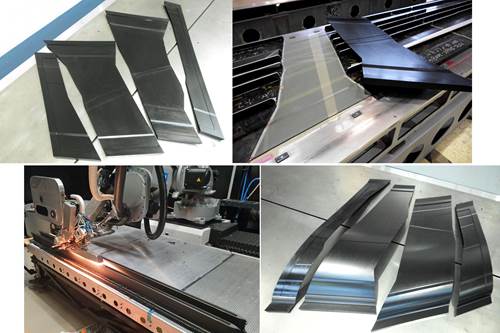

Machina Labs unveils Machina Deployable System for agile manufacturing

Grace Nehls | CompositesWorldPortable system combines AI and robotics for the forming and cutting of custom composite and metal parts.

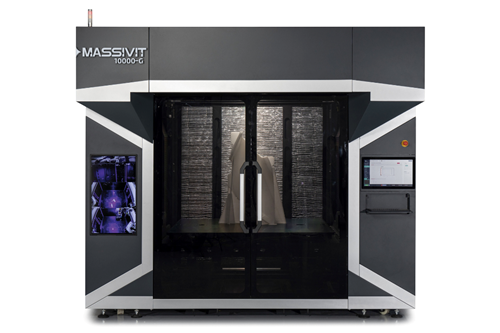

Large-scale additive system prints industrial molds for composites

Grace Nehls | CompositesWorldCAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.