Airborne expands automated kitting partnerships in North America

Preferred Reselling Partners Eastman Machine and Zünd Systemtechnik leverage extensive experience in deploying cutters across diverse end markets to sell Airborne automated kitting solutions.

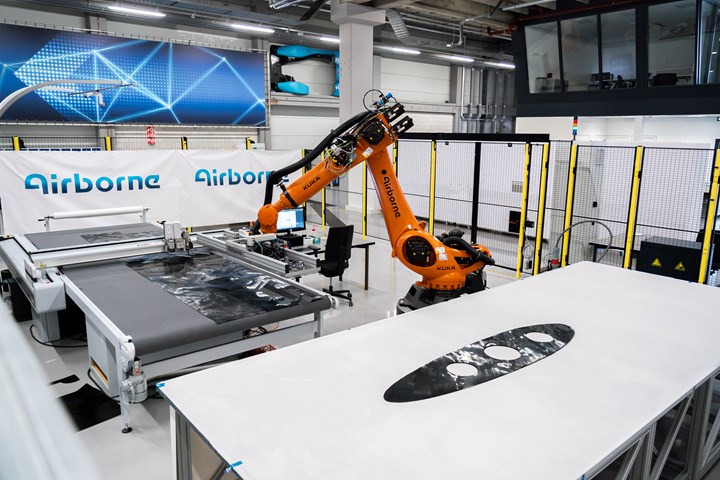

Automated preforming system. Photo Credit: Airborne

To further expand its automated and digital manufacturing services for advanced composites in the North American market, Airborne (The Hague, Netherlands) has appointed two companies, Eastman Machine (Buffalo, N.Y., U.S.) and Zünd Systemtechnik AG (Altstätten, Switzerland), as Preferred Reselling Partners. The partners have rights to sell Airborne automated kitting solutions to the U.S., Canada and Mexico.

Airborne’s automated kitting solutions reportedly reduce operating costs by maximizing material yield through optimized nesting, while simultaneously resolving the challenges inherent in sorting and grouping cut parts from complex nested layouts into laminate-ready kits with minimal operator intervention. Airborne says it offers a portfolio of solutions tailored to meet the individual needs of customers from affordable, entry-level semi-automated products through to fully integrated and high-productivity systems. All systems are “plug and play” and require no additional special programming. Airborne’s software generates the required robotics code directly from information derived from the nesting data and permits static or dynamic nesting and a sorting solution that adapts “on the fly.”

Both Preferred Reselling Partners have been selected due to extensive deployment of cutters and applications across a broad range of end markets.

“Partnering with Eastman and Zünd adds major value for our customers in North America,” notes Joe Summers, Airborne commercial director. “Both share Airborne’s ambitions to make the cutting room more efficient, with the ply cutter at the center of turning materials into cut shapes with the highest possible efficiency of materials and labor. We’re excited to see how this collaboration will bring even more advanced services to customers in North America.”

Zünd, a global, family owned Swiss company, specializes in digital single-ply cutting systems. Zünd has been developing, producing and marketing modular cutting systems since 1984. Its customer base includes global service providers and manufacturers in composites applications, graphics, packaging and leather industries as well as in apparel. Besides Zünd’s own global network of sales and service organizations, the company relies on a worldwide network of long-standing, independent distribution and service partners under the leadership of Oliver Zünd.

“With this distribution agreement, strong partners complement each other in much the same way as strong partnerships we have established in other industries,” adds CEO Oliver Zünd. “Airborne has excellent know-how in developing and manufacturing automated solutions for processing composites. Together we can offer our customers state-of-the-art technology and provide a technological answer to the growing demand for high-performance, innovative production systems in the composites market.”

Similarly, Eastman Machine is a fifth-generation, family operated manufacturer of cutting machines and material handling solutions. Working in tandem with industry engineers, Eastman designs and builds composite cutting machinery that is reliable, accurate and versatile. The company is committed to manufacturing industrial solutions proven to be simpler to operate, less expensive to maintain and customized specific to cutting and handling fiberglass, carbon and aramid reinforcement fibers, as well as other engineered fabrics.

“We are excited about our joint partnership with Airborne,” says Amy Denning, VP of North American Sales at Eastman. “It is a massive step forward for U.S. manufacturers looking to maximize operational efficiency in the cutting room.”

Related Content

-

Optimized CFRP gantry beam enhances Ultimate cutting machines

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

-

Precision sheeters, slitter rewinders are customizable to material needs

CAMX 2024: Pasquato exhibits its high-speed precision sheeters and slitter rewinders to enhance flexibility and material cutting quality.

-

Cutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

.jpg;maxWidth=300;quality=90)