Airbus ESM integration underway for future Artemis moon missions

More than 22,000 elements are begin integrated in parallel in Airbus’ Bremen cleanrooms for ESMs 3, 4 and 5, mission-critical structures for the Orion spacecraft.

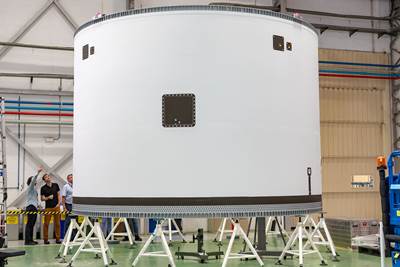

Airbus Bremen cleanroom, housing three ESMs. Photo Credit, all images: Airbus

Airbus (Toulouse, France) is integrating three European Service Modules (ESM) in parallel at its Bremen, Germany-based cleanrooms, with ESM-3 almost complete, ESM-4 underway after its arrival in June 2022 and the newly arrived ESM-5 structure under initial integration.

The ESMs, built for NASA’s (Washington, D.C., U.S.) Orion spacecraft for the Artemis I and II moon missions, comprise a web assembly made of of carbon fiber sheets and aluminum sandwich, and four solar array wings, each composed of three deployable carbon fiber-reinforced polymer (CFRP) rigid panels. Each ESM requires the integration of more than 22,000 elements. According to Airbus, this is the first time that NASA has entrusted a non-U.S. prime — Airbus through the European Space Agency (ESA) — to build a mission-critical element for an American human spaceflight mission.

“Together with the ESA, Airbus is providing half the spacecraft that will return humans to the moon — taking them further than ever before into space and of course returning them safely to Earth,” Marc Steckling, head of space exploration at Airbus, says. “We have already delivered the first two ESMs, with ESM-2 currently being integrated in Orion at [the] Kennedy Space Center. With the arrival of the ESM-4 structure last summer and that of ESM-5 just before Christmas, we have now started the serial production phase. Our cleanroom facilities have been optimized to accommodate three ESMs at the same time, and we are on track to meet NASA’s requirement to deliver one ESM per year going forward.”

The ESM is a critical element of NASA’s crewed Orion spaceship as it provides the spacecraft’s main propulsion system while also enabling orbital maneuvering and positioning control. Electrical power generation and distribution are also provided by the ESM along with supplying the crew with the central elements of life support such as water and oxygen. The ESM also regulates thermal control while it is connected to the crew module. In addition, the unpressurized service module can be used to carry additional payloads. ESA has invested about €2 billion in the Orion program and contracted Airbus to lead the European consortium and build six ESMs to date.

The Orion ESM is cylindrical in shape and approximately four meters in diameter and height. At launch, it weighs just over 13 tonnes, making up roughly 60% of the Orion spacecraft’s total mass. Its 8.6 tonnes of fuel power the main engine, eight auxiliary thrusters and 24 smaller thrusters used for attitude control. The ESM is installed underneath the crew module at Kennedy Space Center in the U.S. Together, they form the Orion spacecraft.

In 2022, the world saw the first Artemis mission with the first Orion spacecraft powered by the ESM-1. The spacecraft traveled more than two million kilometers, was exposed to a temperature range wider than 200°C and flew at a maximum speed of 40,000 kilometers per hour (or 11 kilometers per second). All systems were tested and performed well and reliable, some even better than expected.

ESM-2 was delivered to Florida in October 2021. It is now being tested and integrated at the Kennedy Space Center. It will be part of the crewed Artemis II mission, which will fly the first astronauts around the moon and back to Earth since 1972. The Artemis II launch is currently planned for 2024.

ESM-3 integration.

ESM-3, undergoing final integration, will power the Artemis III mission, set to see the first woman and first person of color setting foot on the moon. The delivery of ESM-3 is planned for the second half of 2023. This mission is envisaged for no earlier than 2025.

ESMs 4, 5 and 6 will be used for the Artemis IV to VI missions, the first two of which are part of the European contribution to the international Gateway, a space station planned to be assembled in lunar orbit. ESA and NASA are aiming to establish a moon ecosystem (Gateway, Argonaut) to better understand and explore all the moon has to offer and in the longer-term to prepare for crewed missions to Mars.

Further ESMs 7, 8 and 9 were authorized at the ESA ministerial council in November 2022, and Airbus is currently finalizing its offer to provide them.

Airbus engineers produce the ESMs together with ESA and industry partners, including suppliers from 10 countries. ESM manufacturing builds on Airbus’ experience gained on the automated transfer vehicle (ATV), which flew five times to the International Space Station (ISS) between 2008 and 2015.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

ESA approves Windform RS, LX 3.0 for space flight applications

CRP Technology’s Top-Line composite materials Windform RS and Windform LX 3.0 are compliant with outgassing requirements in accordance with ESA-TEC-PR-002015.

Read MoreAirbus, ArianeGroup sign transition batch contract for Ariane 6 launch vehicles

Airbus will provide four primary lightweight carbon fibers structures for the next 14 vehicle launchers via state-of-the-art 4.0 industrial facility in Getafe, Spain.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)