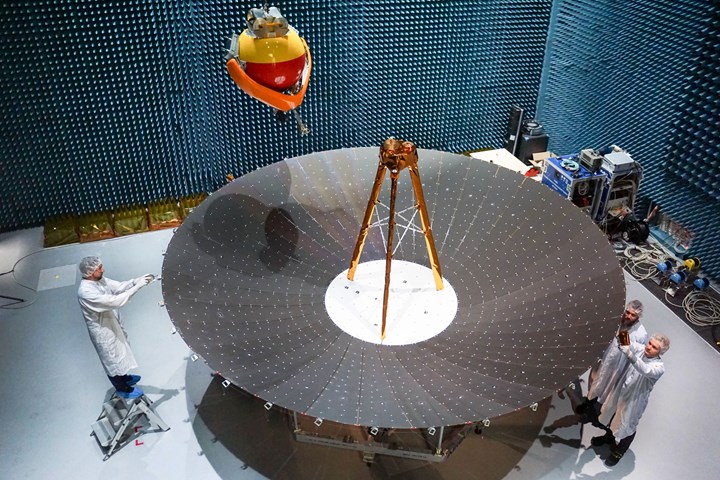

Airbus qualifies Europe's first 5-meter deployable reflector for radar satellites

The unfurlable, parabolic, composite reflector offers significant advantages in satellite deployment and marks Airbus’s entry into the market for cost-effective and small radar missions and constellations.

Photo Credit: Airbus

Airbus (Toulouse, France) reported on Dec. 10 that it has successfully qualified what is says is Europe’s first 5-meter deployable antenna reflector. The 70-kilogram deployable reflector will help enable higher resolution from a radar instrument for Earth observation. Incorporating panels made with high-modulus carbon fiber into the design, Airbus says the semi-rigid reflector technology offers significant advantages compared to classic mesh reflectors.

Due to its large diameter, the reflector would be unable to fit into any rocket fairing, says Airbus. However, this particular antenna reflector is capable of being compactly stowed, and then unfolds like a flower — from 1.6 to 5 meters — after the fairing is released. The unfurlable, parabolic reflector concept enables Airbus to enter the market for cost-effective and small radar missions or constellations.

After successful completion of the intensive deployment and environmental tests, the qualification model has now been delivered to the customer for further tests on the satellite system level. The flight unit will be delivered in 2021 and is currently scheduled for launch for the export customer in 2022.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.