Airbus ramps up A350-1000F freighter developments, manufacture

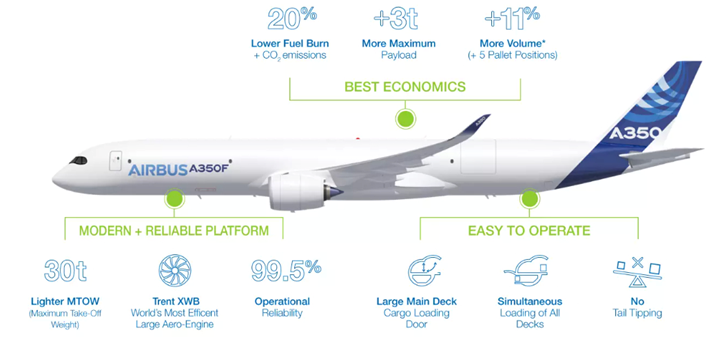

Widebody freighter brings enhanced fuel burn, CO2 emissions and economics compared to other offerings, in addition to adding volume, range and payload.

According to an official report by flightglobal.com, Airbus (Toulouse, France) is ramping up development activity on its A350-1000F freighter, working toward final assembly and first flight milestones in 2025.

The company made an announcement back in November 2021 forecasting new demand for 39,000 new passenger and freighter aircraft by 2040. This progression follows an expected shift from fleet growth to the accelerated retirement of older, less fuel-efficient aircraft. The widebody A350-1000F is one such option to replace these aircraft, being considerably more efficient and sustainable than the 777F, for example.

Per a 2020 Aviation Week article, the composite use for the Airbus A350 Family has “increased significantly from the A380, at 25% composites by weight, to the A350, at 53%.”

Parts currently produced for the A350-1000F include the lower fuselage skin and wing-box feet. In addition, around 30 “large test rigs” have been commissioned to assess individual systems and components, including the environmental control system and cargo loading system (CLS) controls.

Launched in July 2021, the A350F is expected to enter service in 2026. It will be capable of flying 4,700 nautical miles (8,700 kilometers) with a payload of 109 tons, with a maximum 111-ton load on board. A five-frame, 3.2-meter shrink of the A350-1000 passenger aircraft, and using the same Rolls-Royce Trent XWB-97 engines, the new freighter features what Airbus claims is the largest main deck cargo door in the industry — 15% wider than the competition — and a segregated fresh air crew area.

To date, the twinjet has gained 50 orders from nine identified airlines and lessors, plus one undisclosed customer.

According to Airbus’ 2023 full-year financial results, the aerospace company “will continue to invest in our global industrial system, while progressing on our transformation and decarbonization journey,” says Guillaume Faury, Airbus CEO. “Our dividend proposals are a reflection of the strong 2023 financials, our growth prospects in 2024 and balance sheet strength.”

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.