Carbon nanotubes functionalize PP, HDPE structures

Using carbon nanotubes, polypropylene, high-density polyethylene and 3D printing, researchers develop a composite with energy absorption superior to that of aluminum.

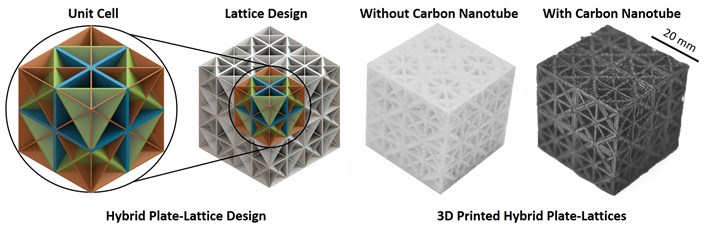

Polypropylene (PP) and high-density polyethylene (HDPE) are two widely used polymers that are low cost, widely available, easy to process, reusable, resistant to solvents and have other benefits, but, as a team of researchers led by engineers at the University of Glasgow (Glasgow, U.K.) point out, the materials have an “unsatisfying impact behavior [low impact strength and penetration resistance]” — which they have addressed by developing a plate-lattice cellular metamaterial that uses multiwall carbon nanotubes (MWCNTs) in the polymer matrix.

The result? “Our nanoengineered hybrid plate-lattices achieve extraordinary stiffness and strength properties and exhibit superior energy absorption characteristics over similar lattices built with aluminum,” says Dr. Shanmugam Kumar, reader in composites and additive manufacturing in the James Watt School of Engineering, who led the project.

This development could have big implications. Kumar says, “One application for this new kind of plate-lattice might be in automobile manufacture, where designers perpetually strive to build more lightweight bodies without sacrificing safety during crashes. Aluminum is used in many modern car designs, but our plate-lattice offers greater impact resistance, which could make it useful in those kinds of applications in the future.”

The polymers were used to create specific geometric structures. The cubic structures have a significant amount of space between the plates, thereby contributing to low mass. The MWCNTs are used to enhance the dynamic energy absorption capacities of the PP and HDPE materials.

To create the structures, the researchers used a fused filament fabrication 3D printing machine, a Creator Pro from Flash Forge (Jinhua, China) fitted with a 0.4-millimeter nozzle.

The plastic materials were sourced from Borouge Pvt. Ltd. (Mumbai, India) and comprise PP random copolymer RA140E (PPR), HDPE and Borcoat ME0433 (HDPE) thermoplastic materials. The MWCNTs, which had an average outer diameter of ~10-12 nanometers and a length of <30 μm, were provided by Applied Nanostructured Solutions LLC (Baltimore, M.D., U.S.).

The researchers found that based on a specific lattice structure, the PPR/6 wt% MWCNT and HDPE/6 wt% MWCNT have a specific energy absorption of 16.1 and 19.9 Joules per gram (J/g), respectively, which is not only higher than aluminum lattices, but comparable to stainless-steel and titanium lattices.

In addition, there is an environmental benefit. Kumar says, “The recyclability of the plastics we’re using in these plate-lattices also makes them attractive as we move towards a net-zero world, where circular economic models will be central to making the planet more sustainable.”

While 3D printing is still limited in terms of output, Kumar adds, “Manufacture of this kind of design at industrial scales is becoming a real possibility.”

The team’s research paper, titled “Impact behaviour of nanoengineered, 3D printed plate-lattices,” is published in Materials & Design and is available at https://doi.org/10.1016/j.matdes.2021.109516.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)