GZero expands FFF 3D printing capabilities to second location

GZero opens another location in West Chester, Ohio, to optimize the production of fiber-reinforced 3D printed parts for service bureau customers.

Share

Read Next

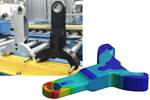

GZero Additive (Elsmere, Ky., U.S.), a producer of large, industrial-grade fused filament fabrication (FFF) 3D printers, announces its expansion to a second location in West Chester Township, Ohio. Founded in January 2022, GZero is a service bureau that makes parts out of a variety of thermoplastics on its machines. It also provides design and engineering services to help service bureau customers optimize their products.

GZero builds systems are offered with build volumes of 415 × 355 × 542 millimeters (16.3 × 13.9 × 21.3 inches) or 415 × 355 × 1042 millimeters (16.3 × 13.9 × 41.0 inches) which can be fitted with single or dual high-volume extruders. Its 3D printers use chopped fiber reinforced materials. According to the company, it can provide prototype or production parts at a fraction of the price of other companies.

Moreover, GZero Additive says it has developed a process that creates low-cost, reusable, 3D printed tooling for wet layup and vacuum resin infusion. In addition to reusable tooling, GZero has also developed a lost-PLA process that enables a mold to be dissolved from a wet layup or vacuum resin infusion part after curing.

The company’s new West Chester Township facility has twice the floor space. Additionally, it was able to lay out the machine assembly and part production departments to optimize production capabilities.

“The new facility is laid out to produce 10 times the number of printers,” says co-founder Michael Parks.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.