Hexagon Purus secures dual-approved hydrogen system order

Landmark order with a 2025 scheduled delivery showcases Hexagon Purus’ dual-approved hydrogen distribution systems, including Type IV tanks, for U.K. and European industrial and mobility applications.

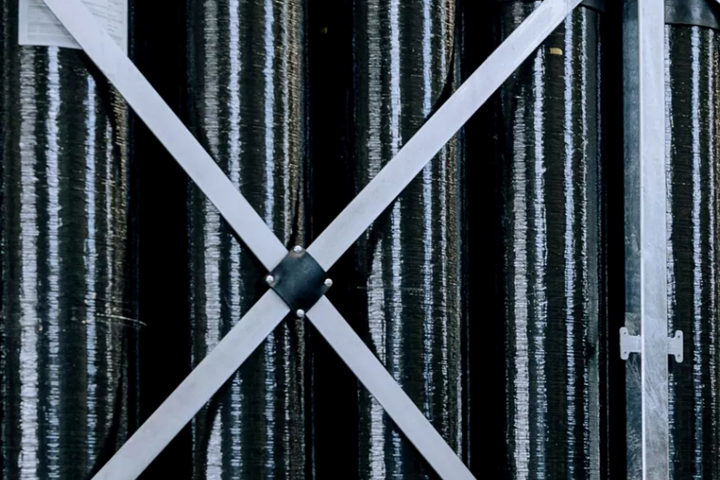

Photo Credit: Hexagon Purus

On Dec. 13, zero-emissions mobility and infrastructure solutions company Hexagon Purus (Oslo, Norway) has received an order for hydrogen distribution systems from a unnamed global industrial gas company in the U.K. Each system will be able to transport more than 1 ton of hydrogen. The value of the order is approximately €3 million (~$3.3 million).

The company’s hydrogen distribution systems, including Type IV hydrogen cylinders, now have dual approval for industrial and mobility applications in the U.K. and Europe. This follows the region’s departure from the EU and new regulatory requirements in the U.K. for hydrogen cylinder storage. The systems will carry the U.K. “Rho” mark, indicating conformity with that region’s standards, and will also retain the “Pi” mark for use in Europe.

“Our distribution systems are ideal to transport hydrogen from production sites to either industrial clients or hydrogen filling stations for mobile applications, allowing for high payloads and reducing total cost of ownership for our customers. With the dual approval we also enable our customer to operate the units outside of the U.K., for example in Ireland or mainland Europe,” says Michael Kleschinski, EVP hydrogen infrastructure and mobility at Hexagon Purus. “This is the first time that our distribution systems are now approved for both the European and U.K. markets, giving our long-standing customer the flexibility to use our hydrogen distribution systems wherever they are needed.”

According to Hexagon Purus, making green hydrogen available for use in industrial processes and mobility is critical to reduce carbon emissions; hydrogen is projected to supply up to 25% of the world’s energy needs by 2050.

Delivery of the hydrogen systems is scheduled for 2025.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.