Hexcel carbon fiber selected for Artemis 9 mission booster production

Lightweight composite design for BOLE boosters enable increased performance for NASA’s future missions to the moon and Mars.

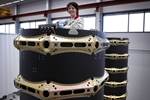

The first BOLE case in winding at the Northrop Grumman Promontory, Utah, facility. Hexcel advanced composites will be used to manufacture the first composite case for BOLE boosters to be used on the Space Launch System (SLS) starting with the Artemis 9 mission, planned for 2031. Photo Credit: Northrop Grumman

Hexcel Corp. (Stamford, Conn., U.S.) announces that its advanced composite materials have been selected by Northrop Grumman (Bethesda, Md., U.S.) to supply the production of the Booster Obsolescence and Life Extension (BOLE) boosters for the Artemis 9 mission. Boosters will support the Space Launch System (SLS) rocket.

The Artemis program is a human spaceflight program that is being led by NASA (Washington, D.C., U.S.) with multiple international and U.S. domestic partners. Its primary goal is to return humans to the moon, specifically the lunar south pole, by 2025.

Northrop Grumman Innovation Systems is working to address space launch system obsolescence issues in booster design and manufacturing. Upgraded boosters using Hexcel’s carbon fiber and prepreg will also reportedly provide increased performance that will benefit future lunar campaigns, science missions and the eventual Mars campaign.

Beginning with the Artemis 9 mission, the new BOLE boosters will replace the steel cases previously used for the space shuttle systems with a weight-saving composite case and upgraded structures, electronic thrust vector control systems and propellant materials to address obsolescence.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

.jpg;maxWidth=300;quality=90)