Hypetex invests in composite manufacturing sustainability

U.K.-based manufacturer joins with SustainableX to address the negative ecological effects of post-process painting of composite components and find more sustainable solutions.

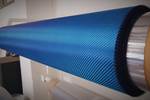

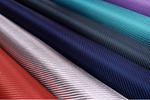

Photo Credit: Hypetex.

Manufacturer and supplier of colored carbon fiber and other advanced materials Hypetex (London, U.K.) announces its collaboration with SustainableX (London) to increase its efforts toward more sustainable composites manufacturing. Specifically, Hypetex is addressing the need for post-process painting.

According to the company, removal of the need for harmful paints could lead to ecological, cost and CO2 reduction benefits for the entire industry. This includes energy reduction needed to paint the part, reduction in final part weight and an overall decrease in carbon emissions.

To achieve this, Hypetex says it has worked with SustainableX to create a tractable model to evaluate its current impact and guide its business decision-making process and manufacturing solution. This will also guide the company’s ongoing improvement policy, which is committed to a sustainable future using the United Nations Sustainability Development Goals (UN SDG), and measure it against the ESG framework.

“Hypetex recognizes and understands how they can, directly and indirectly, contribute to the UN global goals,” says Nick Reilly and Rondi Allan of SustainableX. “Their biggest impacts come from supporting customers to eliminate processes from their production, increase product resilience and lengthen design life. It is great to see them investing in and rapidly developing their measurement systems to include environmental and social impacts. A road map is set out to establish benchmarks and set ambitious targets, to ensure Hypetex continues to authentically contribute to a sustainable future.”

In general, Hypetex endeavors to create value by acting responsibly towards the world in which it operates, contributing to the sustainable development of society and the economy, while placing a consistent focus on ecology and employee welfare. Due to rapidly escalating environmental and ecological concerns globally, Hypetex recognizes that increased efforts are required by companies to acknowledge the significance of sustainability in modern manufacturing.

“Hypetex aims to maintain deeper engagement in social responsibility activities. Sustainability has always been part of our ethos and has helped to guide our choices when selecting chemistries, business suppliers and partners,” adds Marc Cohen, CEO at Hypetex. “We are keen to change the current status quo relying on post-processing painting and the significant negative effect this has on any future sustainability goals. Our business believes in an ecologically friendly future and is invested in the advancement of biomaterials, sustainable chemistries and waste recycling.”

Related Content

-

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.