Jaguar Land Rover composites project to advance EV lightweighting, reduce emissions

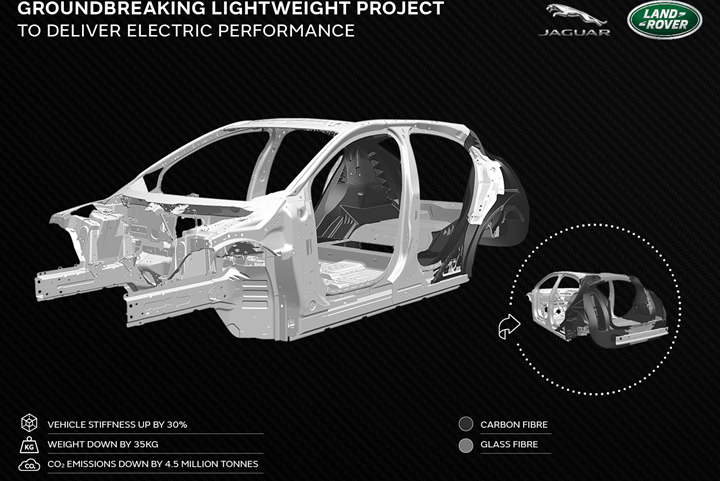

Four-year Tucana project aims to increase vehicle stiffness by 30% cut weight by 35 kilograms, refine crash safety via tailored composites for 2022 prototype fleet.

Share

Photo Credit: Jaguar Land Rover.

Jaguar Land Rover (Whitley, U.K.) is preparing for future electric vehicles (EVs) with advanced lightweight composite research that the company says will help deliver increased range, greater performance and a more dynamic drive.

The Tucana project is a four year program with a goal to make the U.K. a world leader in low-carbon technology, by preventing 4.5 million tonnes of CO2 emissions between 2023 and 2032. This is expected to be achieved by accelerating mainstream use of EVs and lighter vehicles for decreased tailpipe emissions and reduced energy consumption of electrified powertrains.

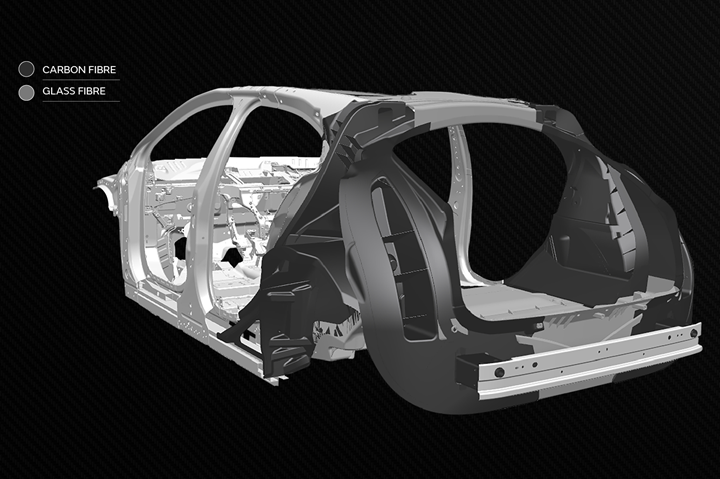

The research itself will enable Jaguar Land Rover to develop lightweight vehicle and powertrain structures by replacing aluminium and steel with composites capable of handling the increased torque generated by high-performance batteries, while improving efficiency and reducing CO2 impact.

Jaguar Land Rover aims to increase vehicle stiffness by 30%, cut weight by 35 kilograms and further refine the crash safety structure through the strategic use of tailored composites, such as carbon and glass fiber. Reducing the vehicle body weight will allow the fitting of larger batteries with increased range — without impacting CO2 emissions. By 2022, Jaguar Land Rover expects to have developed a fleet of prototype Tucana test vehicles.

“The development of new lightweight body structures to complement the latest zero-emissions powertrains will be key as the electrification of our vehicle range continues,” says Marcus Henry, research manager at Jaguar Land Rover. “This project will allow the true environmental credentials of electric vehicles to be realized by enabling wider adoption of the technology and will propel Jaguar Land Rover and the U.K. supply chain into a world-leading position in low-carbon technology.”

The consortium, led by Jaguar Land Rover, is said to bring together world-leading academic and industry partners including the Warwick Manufacturing Group (WMG, Coventry, U.K.), Expert Tooling & Automation (Coventry), Broetje-Automation UK (Wales), Toray International UK (London), CCP Gransden (Northern Ireland) and The Centre for Modelling & Simulation (CFMS, Bristol).

“Tucana shows how new technology development can be optimized and accelerated with digital engineering. Using new digital design, development and manufacturing tools helps to deliver emissions reduction faster, so the U.K. economy can reach zero emissions quicker,” adds Ian Risk, CTO of CFMS.

Photo Credit: Jaguar Land Rover.

According to the company, the continued electrification of Jaguar and Land Rover vehicles is part of a commitment to make societies safer and healthier through innovative technology. Jaguar has completed the electrification of its PACE family with the P300e plug-in hybrid powertrain offered on the new Jaguar E-PACE and P400e for Jaguar F-PACE alongside the all-electric Jaguar I-PACE. Similarly, the new Range Rover Velar is now offered with the P400e, completing the hybrid options available across the Range Rover family.

Related Content

-

Plant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.