Kineco Exel Composites India to supply carbon fiber planks for wind

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

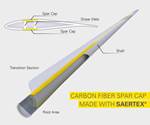

Kineco Exel Composites India (KECI, Goa, India), a joint venture between Exel Composites Plc (Vantaa, Finland) and Kineco Ltd., has signed a multiyear agreement for the supply of pultruded carbon fiber planks for spar caps to a major wind turbine manufacturer in South Asia. Carbon fiber planks are integral parts of wind turbine blades, offering optimal strength, stiffness and low weight as blades continue to grow in length.

The agreement follows the significant development work by KECI and the customer to meet stringent supplier capability and quality requirements, enabling the customer to include an annual minimum volume commitment from the customer to KECI. The parties have agreed not to disclose the contract value.

KECI will be delivering the carbon fiber planks from its new factory near Goa, India, currently in final stages of construction. Deliveries are expected to begin in the second half of 2024, subject to the customer’s product approval protocols and subsequent issuance of purchase orders under the agreement.

“By utilizing KECI’s new factory in India, the customer will be able to avail themselves of state-of-the-art carbon fiber planks produced competitively in India,” says Shekhar Sardessai, managing director of KECI.

Paul Sohlberg, president and CEO of Exel Composites, notes that Exel is in the process of further improving its capabilities to be able to serve the various needs of different customers seeking carbon fiber planks and other composite products for their wind turbines.

Exel Composites and KECI offer wind turbine manufacturers a comprehensive range of glass fiber and carbon fiber composite components required for the manufacturing of modern onshore and offshore blades.

Related Content

-

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

-

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

-

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

.jpg;maxWidth=300;quality=90)